-

Energy Consumption Modeling and Carbon Footprint Analysis in CNC Machining of Biodegradable Plastics

This article provides a comprehensive examination of energy consumption modeling and carbon footprint analysis in the CNC machining of biodegradable plastics.

2025-06-16

-

Multi-Scale Simulation of the Influence of Different Crystalline Structures on CNC Processing Performance of Semi-Crystalline Plastics

Multi-scale simulation has emerged as a powerful tool to bridge the gap between the molecular-level structure of semi-crystalline plastics and their macroscopic processing behavior.

2025-06-15

-

Microstructure Damage in Polymer-Based Composites during Machining

Polymer-based composites, also known as polymer matrix composites (PMCs), are advanced materials composed of a polymeric matrix reinforced with fibers, particles, or other fillers to enhance mechanical, thermal, and electrical properties

2025-06-15

-

CNC Machining of High-Precision Plastic Fasteners for Space Station Maintenance Systems and Mechanical Behavior Stability

This article explores the CNC machining processes for producing these fasteners, the selection of engineering plastics, and the scientific investigation of their mechanical behavior under simulated and actual space conditions.

2025-06-23

-

Study on CNC Machining Mechanism and Surface Quality Control of Polyimide-Based High-Performance Polymers for Aerospace Thermal Structures

This article provides a comprehensive exploration of the CNC machining mechanisms for polyimide-based high-performance polymers, focusing on their application in aerospace thermal structures.

2025-06-23

-

Low-Damage Machining Path and Surface Energy Optimization in CNC Machining of PTFE Materials for Aerospace Insulation Systems

This article explores the principles and practices of low-damage machining paths and surface energy optimization in CNC machining of PTFE for aerospace insulation systems.

2025-06-29

-

Surface Modification and Mechanical Retention Mechanisms of Lightweight and High-Strength Plastics for Deep Space Missions in CNC Machining

This article provides a comprehensive examination of lightweight and high-strength plastics suitable for deep space missions, focusing on their surface modification strategies and mechanical retention mechanisms in the context of CNC machining.

2025-06-23

-

Multi-Axis Dynamic Stability Domain Modeling of Thin-Walled Titanium Alloy Complex Components

This article provides a comprehensive exploration of multi-axis dynamic stability domain modeling for thin-walled titanium alloy complex components.

2025-06-16

-

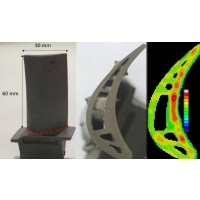

Continuity of Microstructure and Thermal Stress Evolution in Laser Additive Manufacturing-CNC Reprocessed Composite Components

The article is structured to provide a rigorous, scientific examination of the topic, suitable for researchers, engineers, and academics in the fields of materials science, mechanical engineering, and additive manufacturing.

2025-06-30

-

Research on Error Inversion Identification and Physical-Driven Path Optimization System for CNC Machining of Complex Titanium Alloy Multi-Dimensional Free-Form Surfaces

The article is structured into several sections, each addressing a specific aspect of the research, supported by detailed tables for comparative analysis.

2025-06-15

-

Multi-Physics Modeling of Thermal Texture Evolution and Surface Residual Stress During High-Speed Milling of Aviation-Grade High-Strength Aluminum-Lithium Alloys

This article provides a comprehensive exploration of multi-physics modeling techniques for analyzing thermal texture evolution and surface residual stress during HSM of Al-Li alloys.

2025-06-09

-

Evolution Mechanism of Delamination Damage and Fault Suppression Process Strategy in CNC Machining of Aviation Composite Laminated Structure Metal (Titanium Alloy + Carbon Fiber)

This article provides a comprehensive exploration of the evolution mechanism of delamination damage and fault suppression strategies in CNC machining of aviation CFRP/Ti laminated structures, supported by detailed tables for comparative analysis.

2025-06-30

- 5 Axis Machining

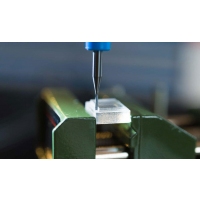

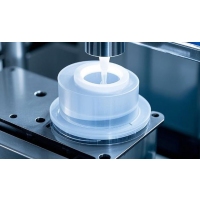

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

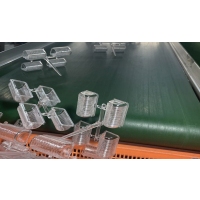

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material