CHINA DIE CASTING SERVICES FOR NON-STANDARD CUSTOM INDUSTRY

ISO 9001:2015 certified custom manufacturer of die, sand and investment castings.

|

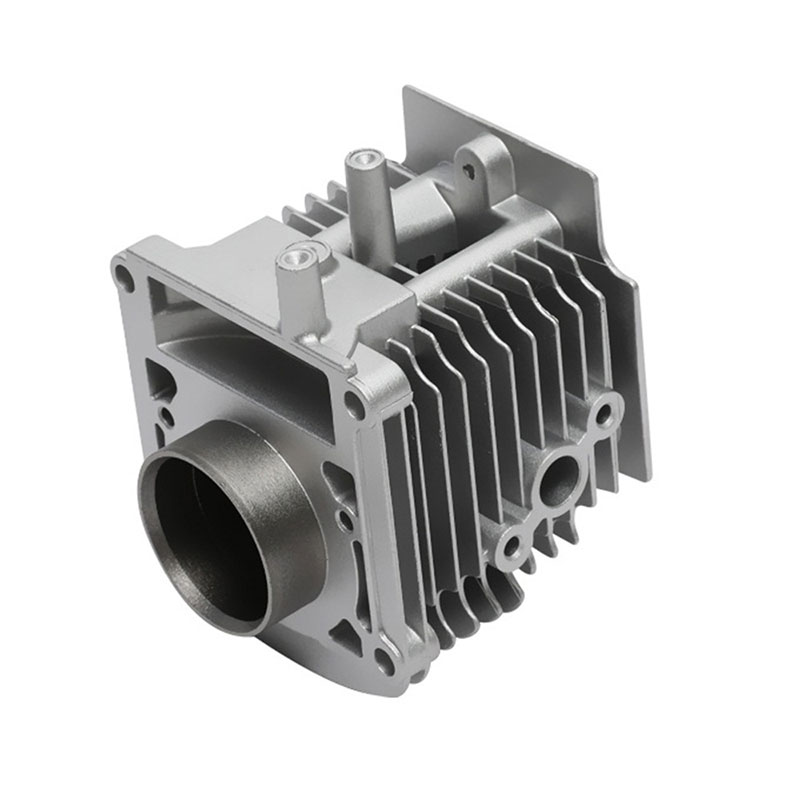

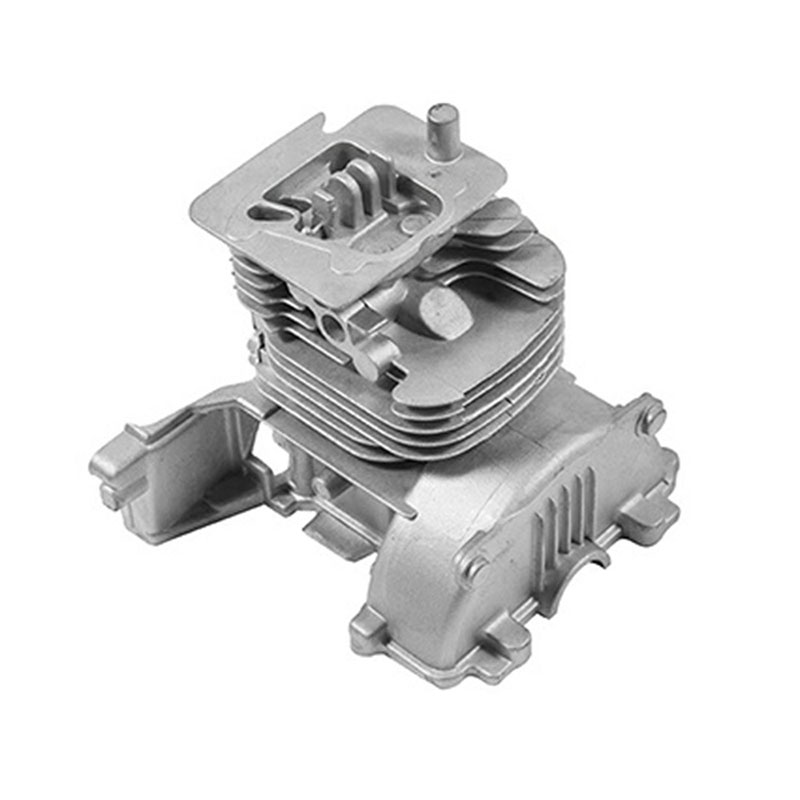

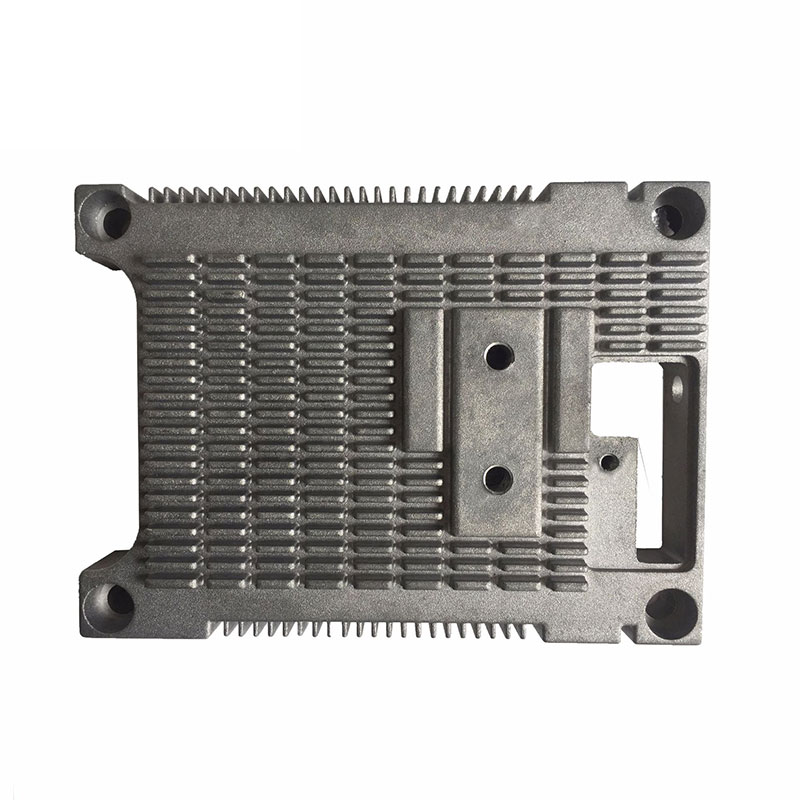

Die casting is the process of making high fidelity copies of your designs by injecting molten metal into custom made steel dies. It’s the most cost effective way to produce medium to high volumes of metal parts with excellent surface finish and dimensional accuracy. PTJ Shop Is ISO 9001:2015 and AS 9100 Rev. C certified custom manufacturer offering die castings. Capable of handling parts weighing from 1 oz. to 10 lbs. Available in short to medium-sized runs with up to 100,000 production pieces.Capabilities are investments, iron, steel, zinc, lost wax, ferrous sand, permanent mold, and gravity castings. Also capable of molding, CNC machining, stamping, tooling, and finishing. Material include aluminum、brass & zinc etc.Industries served include industrial lighting, automotive, medical, agriculture, off-road vehicles, telecommunications, electronics, and meter components industries. PTJ Shop offers a complete range of pressure die casting services. These include mold tool making, die casting, machining, polishing and plating. Our advanced inspection and test equipment ensures the quality of your raw materials and your finished parts. We invite you to experience our professional service at an unbeatable price when you send us your CAD files for a free quote. |

|

|

|

|

|

|

|

|

|

Contact our die casting services enginers today to discuss the specifics of your complex parts. |

1.Precision custom manufacturer of aluminum die castings.

Aluminum die castings are available in alloys including 380 & 383. Specifications include plus /- 0.0025 tolerances & maximum molding weight of 10 lbs.2.Custom manufacturer of brass die castings.

Available with low density, higher strength to density ratio, higher conductivity, non-magnetic, corrosion resistance and many other properties.Process such as high and low pressure, air set, hot chamber, loose pattern, pressure cast and tight, impregnation and tilt poured offered. Castings are abrasion, acid, wear, heat and corrosion resistant. .3.Custom manufacturer of zinc die castings.

Zinc die castings are available in standard & hybrid alloys. Standard zinc alloys include Zamak no. 3, Zamak no. 5 & Zamak no. 7. Hybrid zinc alloys include ZA-8 & ZA-27. Specifications include plus /- 0.001 tolerances & maximum molding weight of 4.5 lbs.

|

|

|

|

|

|

|

High Accuracy |

Quick Quote& Service |

Fast Delivery |

Custom Finishes |

Precision Machines |

Addition Services |

|

|

Contact our Die Casting Shop to discuss your custom part needs today. |

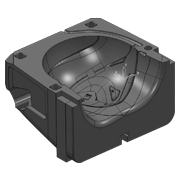

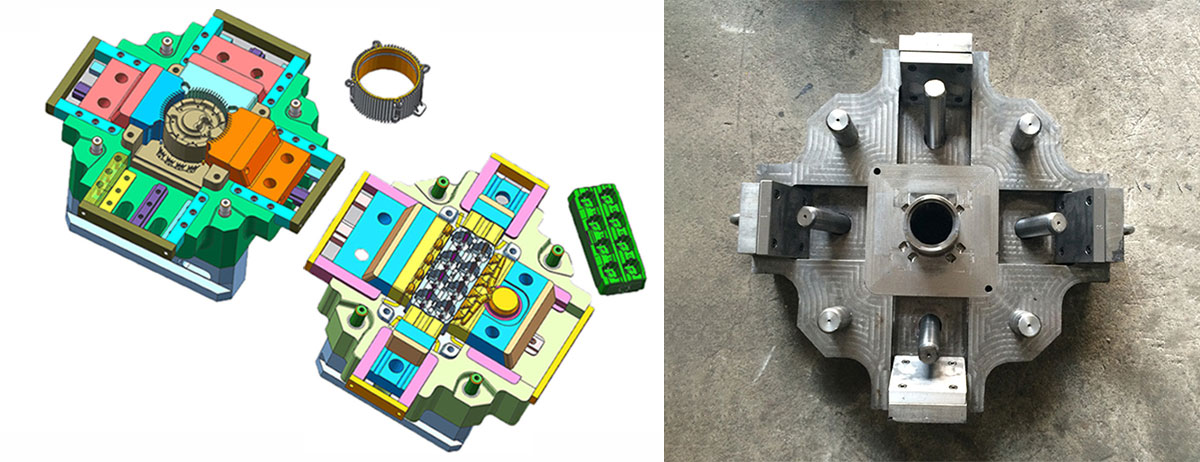

Die Casting Parts And Mold Capabilities

The success of your pressure die casting project depends on the quality of the mold tools, and our tool making abilities are unmatched in China. After we receive your order, we will:-

▶ Perform a complete Design for Manufacturing review of your CAD files

- ▶ Verify tooling raw materials for compliance.

-

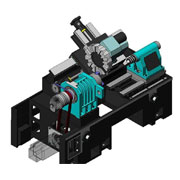

▶ Use our multi-axis imported CNC machine tools to fabricate the core and cavity.

- ▶ Apply careful heat treating to temper the molds.

- ▶ Exercise process control when casting your parts.

- ▶ Provide any necessary post-machining or processing.

-

▶ Professionally inspect and measure finished parts to meet and exceed your specifications.

-

▶ An Esprit CAD/CAM system to precisely produce the most elaborate geometries (complete equipment list)

View more machining technology on our Gallery Page

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years. Let’s view the other machining technology and learn more calture about PTJ Hardware.

|

|

|

|

|

| View Detail >> | 1 | View Detail >> | 1 | View Detail >> |

|

|

|

|

|

|

|

|

|

|

|

| View Detail >> |

|

View Detail >> |

|

View Detail >> |