Multi-Physics Modeling of Thermal Texture Evolution and Surface Residual Stress During High-Speed Milling of Aviation-Grade High-Strength Aluminum-Lithium Alloys

Aviation-grade high-strength aluminum-lithium (Al-Li) alloys are pivotal in the aerospace industry due to their exceptional combination of low density, high specific strength, excellent corrosion resistance, and enhanced fatigue properties. These alloys, such as AA2050, AA2099, and AA2195, are increasingly utilized in critical structural components like fuselage panels, wing skins, and load-bearing frames, where lightweight design and mechanical performance are paramount. High-speed milling (HSM), a precision machining process characterized by elevated cutting speeds and feed rates, is widely employed to shape these alloys into complex geometries with stringent dimensional tolerances. However, the multi-physics interactions during HSM—encompassing mechanical, thermal, and microstructural phenomena—introduce significant challenges, particularly in controlling thermal texture evolution and surface residual stresses. These factors critically influence the machined component’s surface integrity, fatigue life, and overall performance in service.

The complexity of HSM arises from the interplay of cutting forces, frictional heat generation, plastic deformation, and dynamic recrystallization, all of which contribute to microstructural changes and residual stress states. Thermal texture evolution refers to the development of crystallographic texture driven by localized heating and deformation, while surface residual stresses result from the combined effects of mechanical loads and thermal gradients. Understanding and predicting these phenomena require sophisticated multi-physics modeling approaches that integrate computational mechanics, thermodynamics, and materials science. Such models enable researchers and engineers to optimize machining parameters, enhance surface quality, and mitigate defects like cracking or distortion in aerospace components.

This article provides a comprehensive exploration of multi-physics modeling techniques for analyzing thermal texture evolution and surface residual stress during HSM of Al-Li alloys. It synthesizes recent advancements in experimental and computational methodologies, drawing from finite element analysis (FEA), crystal plasticity models, and phase-field simulations. The discussion is structured to address the material properties of Al-Li alloys, the mechanics of HSM, thermal and mechanical modeling frameworks, texture evolution mechanisms, residual stress formation, and practical strategies for process optimization. Detailed tables are included to compare material properties, modeling approaches, and experimental outcomes, ensuring a rigorous and scientifically grounded presentation.

Aluminum-Lithium Alloys: Composition and Properties

Overview of Al-Li Alloys

Aluminum-lithium alloys represent a class of advanced materials engineered to meet the demanding requirements of aerospace applications. The addition of lithium, typically ranging from 0.5 to 3 wt.%, reduces the alloy’s density by approximately 3% per 1 wt.% of lithium while increasing the elastic modulus by about 6%. These alloys also exhibit superior fatigue crack growth resistance, fracture toughness, and corrosion resistance compared to conventional aluminum alloys like AA7075 or AA2024. Third-generation Al-Li alloys, such as AA2050, AA2099, and AA2195, have been developed to address earlier challenges, including anisotropy and weldability, by optimizing compositions with elements like copper (Cu), magnesium (Mg), and zirconium (Zr).

Composition and Microstructural Characteristics

The composition of Al-Li alloys significantly influences their mechanical and thermal properties. Lithium enhances the formation of coherent δ′ (Al₃Li) precipitates, which contribute to precipitation hardening but also introduce planar slip, leading to anisotropic mechanical behavior. Other alloying elements, such as Cu, promote the formation of T₁ (Al₂CuLi) and θ′ (Al₂Cu) phases, while Zr facilitates grain refinement through Al₃Zr dispersoids, improving ductility and controlling texture during thermomechanical processing. Table 1 summarizes the typical compositions of key Al-Li alloys used in aerospace applications.

**Table 1: Typical Chemical Compositions of Aviation-Grade Al-Li Alloys (wt.%)**

|

Alloy |

Al |

Li |

Cu |

Mg |

Zr |

Mn |

Fe |

Si |

Others |

|---|---|---|---|---|---|---|---|---|---|

|

AA2050 |

Bal. |

0.7–1.3 |

3.2–3.9 |

0.2–0.6 |

0.06–0.14 |

0.2–0.5 |

≤0.1 |

≤0.1 |

Ag: 0.2–0.7 |

|

AA2099 |

Bal. |

1.6–2.0 |

2.4–3.0 |

0.1–0.5 |

0.05–0.12 |

0.1–0.5 |

≤0.07 |

≤0.05 |

Zn: ≤0.9 |

|

AA2195 |

Bal. |

0.8–1.2 |

3.7–4.3 |

0.25–0.8 |

0.08–0.16 |

≤0.25 |

≤0.15 |

≤0.12 |

Ag: 0.25–0.6 |

|

AA2198 |

Bal. |

0.8–1.1 |

2.9–3.5 |

0.1–0.5 |

0.04–0.18 |

≤0.5 |

≤0.1 |

≤0.08 |

Zn: ≤0.35 |

Notes: Bal. = Balance; Fe and Si are impurities; Others include trace elements like Ti, Sc, or Ce for specific alloys.

Mechanical and Thermal Properties

The mechanical properties of Al-Li alloys, such as high specific strength and stiffness, make them ideal for aerospace components subjected to high loads. For instance, AA2099 exhibits a yield strength of approximately 450–550 MPa and an ultimate tensile strength (UTS) of 500–600 MPa after T8 tempering. However, their high strength comes at the cost of increased anisotropy due to crystallographic texture, particularly in wrought products. Thermally, Al-Li alloys have good conductivity (approximately 30–40% IACS) but are susceptible to thermal softening during high-temperature processes like HSM, necessitating precise control of machining conditions.

Table 2 compares the mechanical and thermal properties of selected Al-Li alloys with conventional aluminum alloys.

**Table 2: Mechanical and Thermal Properties of Al-Li and Conventional Aluminum Alloys**

|

Alloy |

Density (g/cm³) |

Yield Strength (MPa) |

UTS (MPa) |

Young’s Modulus (GPa) |

Thermal Conductivity (W/m·K) |

|---|---|---|---|---|---|

|

AA2050 |

2.70 |

470–520 |

510–570 |

76 |

130–150 |

|

AA2099 |

2.63 |

450–550 |

500–600 |

77 |

120–140 |

|

AA2195 |

2.71 |

480–540 |

520–620 |

78 |

125–145 |

|

AA7075-T6 |

2.81 |

500–540 |

560–590 |

71 |

130–160 |

|

AA2024-T3 |

2.78 |

345–400 |

480–520 |

73 |

120–150 |

Notes: Values are approximate and depend on specific heat treatment and processing conditions.

High-Speed Milling: Process Mechanics and Challenges

Fundamentals of High-Speed Milling

High-speed milling is defined by cutting speeds exceeding 1000 m/min, often reaching 2000–5000 m/min for aluminum alloys, coupled with high feed rates and low depths of cut. This process leverages high spindle speeds and advanced tool materials (e.g., carbide or polycrystalline diamond) to achieve superior material removal rates (MRR) and surface finishes. In aerospace manufacturing, HSM is critical for machining thin-walled structures and complex geometries, such as monolithic components in Al-Li alloys, which constitute up to 90% of material removal in some applications.

The mechanics of HSM involve a dynamic interplay of cutting forces, tool-workpiece interactions, and heat generation. The cutting tool engages the workpiece in a cyclic manner, producing chips through shear deformation while generating significant frictional heat at the tool-chip interface. For Al-Li alloys, the high thermal conductivity and low melting point (approximately 600–650°C) amplify thermal effects, leading to localized temperature rises that influence microstructure and residual stresses.

Challenges in HSM of Al-Li Alloys

The primary challenges in HSM of Al-Li alloys include:

-

Thermal Effects: High cutting speeds generate temperatures up to 300–500°C at the tool-workpiece interface, promoting thermal softening, dynamic recrystallization, and phase transformations.

-

Residual Stresses: Mechanical loads and thermal gradients induce complex residual stress profiles, with tensile stresses on the surface potentially compromising fatigue life.

-

Texture Evolution: Deformation and thermal cycles during HSM drive crystallographic texture changes, affecting mechanical anisotropy and formability.

-

Tool Wear and Vibration: The high strength and abrasiveness of Al-Li alloys accelerate tool wear, while thin-walled structures are prone to chatter, impacting surface quality.

-

Surface Integrity: Achieving low surface roughness (Ra < 0.8 µm) and minimal subsurface damage is critical but challenging due to the alloys’ sensitivity to machining parameters.

These challenges necessitate advanced modeling to predict and control the multi-physics interactions during HSM, ensuring optimal performance of machined components.

Multi-Physics Modeling Frameworks

Overview of Multi-Physics Modeling

Multi-physics modeling integrates multiple physical domains—mechanical, thermal, and microstructural—to simulate the complex interactions during HSM. Key approaches include:

-

Finite Element Analysis (FEA): Models cutting forces, thermal fields, and residual stresses using continuum mechanics.

-

Crystal Plasticity Models: Capture microstructural evolution and texture changes at the grain scale.

-

Phase-Field Methods: Simulate phase transformations and recrystallization kinetics.

-

Coupled Thermo-Mechanical Models: Combine thermal and mechanical effects to predict stress and texture evolution.

These frameworks rely on constitutive models, such as the Johnson-Cook model, to describe material behavior under high strain rates and temperatures, and they are often validated through experimental techniques like X-ray diffraction (XRD) and electron backscatter diffraction (EBSD).

Finite Element Analysis for HSM

FEA is widely used to simulate the cutting process, capturing the thermo-mechanical coupling in HSM. The governing equations include:

-

Momentum Balance: [ \nabla \cdot \sigma + \rho b = \rho \ddot{u} ] where (\sigma) is the stress tensor, (\rho) is density, (b) is body force, and (\ddot{u}) is acceleration.

-

Energy Balance: [ \rho c_p \frac{\partial T}{\partial t} = \nabla \cdot (k \nabla T) + Q ] where (c_p) is specific heat, (T) is temperature, (k) is thermal conductivity, and (Q) is heat generation from plastic work and friction.

FEA models discretize the workpiece and tool into elements, solving for stress, strain, and temperature distributions. For Al-Li alloys, FEA has been used to predict cutting forces, temperature profiles, and residual stresses under various conditions, including dry, minimum quantity lubrication (MQL), and cryogenic cooling. Table 3 compares different FEA-based models for HSM of Al-Li alloys.

**Table 3: Comparison of FEA-Based Models for HSM of Al-Li Alloys**

|

Model Type |

Software |

Key Features |

Outputs |

Limitations |

Reference |

|---|---|---|---|---|---|

|

2D Orthogonal Cutting |

ABAQUS |

Johnson-Cook constitutive model, frictional heat |

Cutting forces, surface temperature |

Simplified geometry, neglects 3D effects |

|

|

3D Milling |

DEFORM-3D |

Coupled thermo-mechanical, adaptive meshing |

Residual stress, chip morphology |

High computational cost |

|

|

Cryogenic Cooling |

COMSOL |

Thermo-mechanical coupling, LN2 cooling |

Surface residual stress, temperature |

Limited to specific cooling conditions |

|

|

Hybrid FEA-Statistical |

ANSYS |

Combines FEA with response surface methodology |

Residual stress prediction |

Requires extensive experimental data |

Crystal Plasticity Modeling

Crystal plasticity models simulate texture evolution by resolving slip and twinning mechanisms at the grain scale. These models use the Orientation Distribution Function (ODF) to describe crystallographic texture and incorporate constitutive laws like the Voce hardening model to capture strain hardening and texture changes. The governing equation for plastic deformation is:

[ \dot{\gamma}^\alpha = \dot{\gamma}_0 \left( \frac{|\tau^\alpha|}{\tau_c^\alpha} \right)^n \text{sgn}(\tau^\alpha) ]

where (\dot{\gamma}^\alpha) is the shear rate on slip system (\alpha), (\tau^\alpha) is the resolved shear stress, (\tau_c^\alpha) is the critical resolved shear stress, and (n) is the strain rate sensitivity exponent.

For Al-Li alloys, crystal plasticity models predict the evolution of texture components like Brass {110}<112> and Cube {100}<001> during HSM, which influence mechanical anisotropy. These models are computationally intensive but provide detailed insights into microstructural changes.

Phase-Field and Microstructural Models

Phase-field methods simulate dynamic recrystallization (DRX) and phase transformations by tracking the evolution of order parameters. The phase-field equation is:

[ \frac{\partial \phi}{\partial t} = -M \frac{\delta F}{\delta \phi} ]

where (\phi) is the phase-field variable, (M) is mobility, and (F) is the free energy functional. These models are particularly useful for studying continuous dynamic recrystallization (CDRX) in Al-Li alloys, which occurs during HSM due to high strain rates and temperatures.

Thermal Texture Evolution in HSM

Mechanisms of Texture Evolution

Thermal texture evolution in HSM of Al-Li alloys is driven by a combination of plastic deformation, thermal gradients, and recrystallization. Key mechanisms include:

-

Slip System Activation: High shear strains activate multiple slip systems, leading to texture components like Copper {112}<111> and S {123}<634>.

-

Dynamic Recrystallization (DRX): Localized heating promotes DRX, resulting in fine, equiaxed grains and texture randomization.

-

Thermal Softening: Elevated temperatures reduce flow stress, altering slip system activity and texture development.

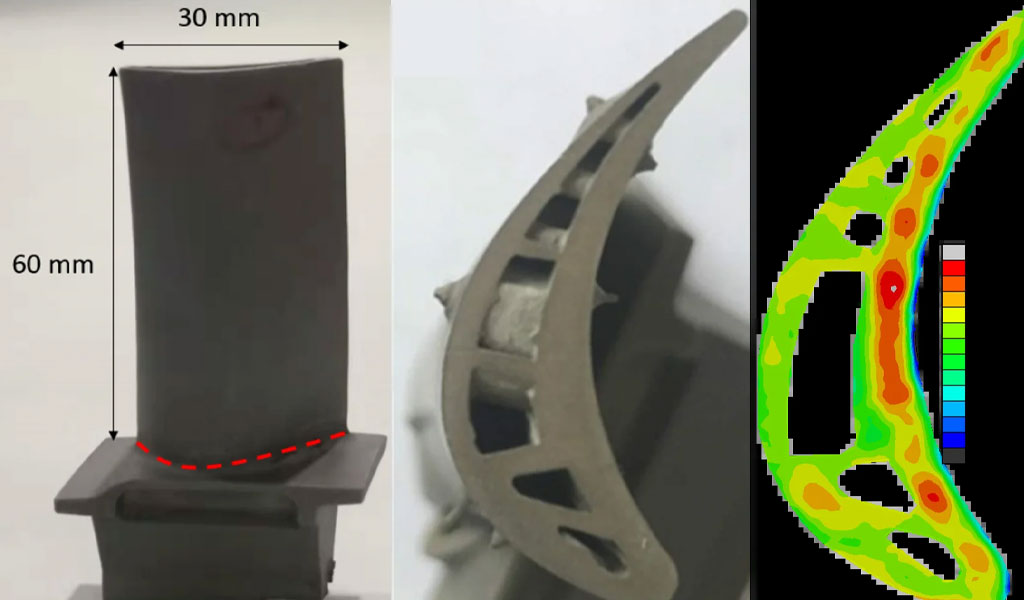

The strong initial texture of Al-Li alloys, often developed during hot extrusion or rolling, evolves during HSM due to the cyclic loading and thermal cycles. EBSD studies reveal that high-speed milling can reduce texture intensity by promoting CDRX, particularly in alloys like AA2099.

Modeling Texture Evolution

Crystal plasticity finite element models (CPFEM) and ODF-based models are used to predict texture evolution. For example, a multi-scale model for AA2070 Al-Li alloy simulates texture changes during deformation by coupling macro-scale FEA with micro-scale ODF updates. These models show that high cutting speeds reduce texture anisotropy by enhancing recrystallization, while low feed rates preserve stronger textures due to limited thermal input.

Table 4 summarizes experimental and modeling studies on texture evolution in Al-Li alloys during HSM.

**Table 4: Studies on Texture Evolution in Al-Li Alloys During HSM**

|

Alloy |

Process |

Texture Components |

Modeling Approach |

Key Findings |

Reference |

|---|---|---|---|---|---|

|

AA2070 |

HSM |

Brass, Cube |

CPFEM with ODF |

Reduced anisotropy with high cutting speed |

|

|

AA2099 |

Extrusion + HSM |

Copper, S |

VPSC model |

CDRX reduces texture intensity |

|

|

AA2195 |

Milling |

Goss, Cube |

Phase-field |

Equiaxed grains form at high temperatures |

|

|

AA2050 |

Cryogenic HSM |

Brass, S |

FEA + EBSD |

Cryogenic cooling minimizes texture changes |

Surface Residual Stress Formation

Mechanisms of Residual Stress

Surface residual stresses in HSM arise from the superposition of mechanical and thermal loads:

-

Mechanical Loads: Cutting forces induce compressive stresses through plastic deformation, while tool wear increases tensile stresses.

-

Thermal Loads: Frictional heat generates tensile stresses due to thermal expansion and subsequent cooling.

-

Coupled Effects: Thermo-mechanical coupling amplifies stress gradients, particularly in thin-walled components.

In Al-Li alloys, tensile residual stresses on the surface (up to 200–300 MPa) are detrimental to fatigue life, while compressive stresses (100–200 MPa) in the subsurface enhance durability. Cryogenic cooling, using liquid nitrogen (LN2), has been shown to reduce tensile stresses by lowering cutting temperatures.

Modeling Residual Stress

Residual stress models combine FEA with empirical or statistical approaches to predict stress profiles. For example, Jiang et al. used a quantitative FEA model to show that cutting forces dominate radial residual stress in Al-Li alloys, while thermal loads have a weaker effect at low velocities. The stress tensor is computed as:

[ \sigma_r = \sigma_m + \sigma_t ]

where (\sigma_r) is the residual stress, (\sigma_m) is the mechanical component, and (\sigma_t) is the thermal component.

Table 5 compares residual stress modeling approaches for HSM of Al-Li alloys.

**Table 5: Residual Stress Modeling Approaches for HSM of Al-Li Alloys**

|

Model |

Alloy |

Stress Type |

Key Parameters |

Validation Method |

Reference |

|---|---|---|---|---|---|

|

FEA |

AA2050 |

Tensile/Compressive |

Cutting speed, feed rate |

XRD, FEA |

|

|

Hybrid FEA-Statistical |

AA7075 |

Surface Tensile |

Tool wear, depth of cut |

XRD, ANOVA |

|

|

Cryogenic FEA |

AA2195 |

Compressive |

LN2 flow rate, velocity |

EBSD, XRD |

|

|

Empirical |

AA2099 |

Tensile |

Feed rate, spindle speed |

Electro-polishing, XRD |

Experimental Validation and Techniques

Measurement Techniques

Experimental validation of multi-physics models relies on advanced characterization techniques:

-

X-Ray Diffraction (XRD): Measures residual stresses by analyzing lattice strain.

-

Electron Backscatter Diffraction (EBSD): Maps crystallographic texture and grain size.

-

Infrared Thermography: Captures surface temperature profiles during HSM.

-

Dynamometry: Quantifies cutting forces using piezoelectric sensors.

These techniques confirm model predictions, such as the reduction of tensile residual stresses under cryogenic cooling or the formation of equiaxed grains via CDRX.

Case Studies

Recent studies validate multi-physics models for HSM of Al-Li alloys:

-

Cryogenic Milling of AA2195: Cryogenic cooling reduced surface temperatures by 30–50% and shifted residual stresses from tensile to compressive, improving fatigue life.

-

Texture Evolution in AA2099: EBSD analysis confirmed that high cutting speeds promote CDRX, reducing texture intensity and anisotropy.

-

Residual Stress in AA7050: XRD measurements showed that tool flank wear increases tensile stresses by 20–30% due to enhanced thermal loads.

Optimization Strategies for HSM

Process Parameter Optimization

Optimizing HSM parameters—cutting speed, feed rate, depth of cut, and cooling conditions—minimizes residual stresses and controls texture evolution. Key strategies include:

-

High Cutting Speeds: Speeds above 2000 m/min reduce texture anisotropy by promoting DRX but increase thermal loads.

-

Low Feed Rates: Feed rates below 0.1 mm/rev minimize mechanical stresses and surface roughness.

-

Cryogenic Cooling: LN2 cooling reduces temperatures and tensile stresses, enhancing surface integrity.

-

Tool Geometry: Sharp tools with low rake angles reduce cutting forces and heat generation.

Advanced Cooling Techniques

Cryogenic cooling and MQL are effective in managing thermal effects. Cryogenic milling with LN2 lowers cutting temperatures to 100–200°C, reducing thermal stresses and promoting compressive residual stresses. MQL, using minimal lubricant, reduces friction but is less effective than cryogenic cooling for Al-Li alloys.

Table 6 summarizes the impact of cooling strategies on HSM outcomes.

**Table 6: Impact of Cooling Strategies on HSM of Al-Li Alloys**

|

Cooling Method |

Temperature Reduction (°C) |

Residual Stress (MPa) |

Surface Roughness (µm) |

Reference |

|---|---|---|---|---|

|

Dry Milling |

0 |

Tensile: 200–300 |

0.8–1.2 |

|

|

MQL |

50–100 |

Tensile: 150–250 |

0.6–0.9 |

|

|

Cryogenic (LN2) |

100–200 |

Compressive: -100 to -200 |

0.4–0.6 |

|

|

Flood Cooling |

80–150 |

Tensile: 100–200 |

0.5–0.8 |

Tool Design and Coatings

Tool materials like polycrystalline diamond (PCD) and coatings like TiAlN reduce wear and heat generation, improving surface quality. Optimized tool geometries, such as high helix angles, minimize vibration and chatter in thin-walled Al-Li components.

Future Directions and Challenges

Emerging Modeling Techniques

Advancements in multi-physics modeling include:

-

Machine Learning Integration: Combining FEA with machine learning to predict texture and stress with reduced computational cost.

-

Multi-Scale Models: Coupling macro-scale FEA with micro-scale crystal plasticity for comprehensive texture prediction.

-

Real-Time Simulation: Developing real-time models for in-process monitoring and control of HSM.

Challenges in Modeling and Experimentation

Key challenges include:

-

Computational Cost: High-fidelity models like CPFEM require significant computational resources.

-

Material Variability: Variations in alloy composition and initial microstructure complicate model accuracy.

-

Experimental Validation: Limited access to advanced characterization tools like synchrotron XRD hinders validation.

Industrial Applications

The insights from multi-physics modeling are being applied to optimize HSM for aerospace components, such as the Boeing 787’s fuselage and the Airbus A380’s wing skins, where Al-Li alloys are prevalent. Future research aims to integrate these models into computer-aided manufacturing (CAM) systems for real-time process control.

Conclusion

Multi-physics modeling of thermal texture evolution and surface residual stress during high-speed milling of aviation-grade Al-Li alloys is a critical research area that bridges materials science, computational mechanics, and manufacturing engineering. By integrating FEA, crystal plasticity, and phase-field models, researchers can predict and control the complex interactions of mechanical, thermal, and microstructural phenomena. Experimental validation using XRD, EBSD, and thermography confirms the accuracy of these models, while optimization strategies like cryogenic cooling and advanced tool design enhance surface integrity and component performance. Despite challenges in computational cost and material variability, ongoing advancements in modeling and experimental techniques promise to further improve the precision and efficiency of HSM for Al-Li alloys, ensuring their continued dominance in aerospace applications.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material