-

Exploring Swiss Type Lathes: Mechanics, Operations, and Applications

In this comprehensive article, we will delve deep into the world of Swiss Type Lathes, unraveling their intricate mechanics and shedding light on how they work. We'll also explore their applications, advantages, and evolving technology.

2023-10-23

-

How to process round corners?

Whether it is manual operation or equipment processing-more and more sheet metal processing companies are beginning to integrate rounding processing into the part processing process chain.

2021-10-22

-

Best CNC Lathe Types & Parts – Exploring 8 Different Components of CNC Lathe Machines and Their Types

In this comprehensive article, we will delve deep into the world of CNC lathes, exploring the eight essential components of these machines and discussing the various types available in the market.

2023-09-18

-

The cutting fluid produces bubbles, how can we solve it?

In the metal cutting and grinding process, cutting fluid is an industrial liquid used to cool and lubricate tools and processed parts. The reasonable use of cutting fluid in cutting can not only reduce the friction between the tool and the chip, the tool and the processing surface, but also It can reduce the cutting force and cutting temperature, reduce tool wear, and improve the quality of the machined surface. But what do you know about the classification of cutting fluid? What is the choice of cutting fluid?

2021-10-22

-

How To Reduce The Cost Of Manufacturing During CNC Lathing

In the world of precision machining, CNC (Computer Numerical Control) lathing is a fundamental process that plays a crucial role in the production of various components.

2023-09-26

-

Get to know the four metal 3D printing technologies

Metal 3D printing is considered the culmination of all 3D printing. When it comes to strength and durability, nothing can compare to metal. The earliest metal 3D printing patent was DMLS (Direct Metal Laser Sintering), which was obtained by the German EOS in the 1990s.

2021-10-22

-

What is an Engine Lathe & How Does It Work

In the world of precision machining, the engine lathe stands as an enduring symbol of craftsmanship, versatility, and engineering excellence. It's a cornerstone tool in manufacturing and metalworking industries, renowned for its ability to turn raw materials into precise and intricate components

2023-09-29

-

This article takes you to learn more about the process method of aluminum alloy welding

Aluminum alloy welding is very different from the welding of ordinary carbon steel, stainless steel and other materials. It is easy to produce many defects that other materials do not have, and it is necessary to adopt targeted measures to avoid it. Let's take a look at the problems that are prone to aluminum alloy welding and the requirements for welding technology.

2021-10-22

-

The Molding Method Of Industrial Ceramic Machining

Mechanical accessories made of modern industrial ceramics are widely used in military ceramics, textile ceramics, electronic and electrical ceramics, etc. So do you know how industrial ceramics are formed? What are the methods? Kezhong Ceramics will tell you.

2022-05-20

-

Analysis of common quality problems of steel and their causes

The common quality problems of steel are mainly: surface defects, internal defects, and external dimension defects. These three problems will be introduced below:

2021-10-22

-

The Reference For Lost Foam Castings Cost Accounting

Cost analysis is very simple and can include two aspects, namely cost increase factors and cost reduction factors. The difference between these two factors is the amount of cost increase or decrease after the lost foam casting process is adopted.

2021-11-27

-

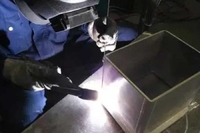

What factors affect the appearance of argon arc welding porosity?

Aiming at the common vent problems in manual argon arc welding, based on the author's years of work experience in manual argon arc welding, the reasons for the pores in argon arc welding are analyzed, and some solutions and attention are introduced. matter. Help welders to deal with such problems encountered in actual production, and better master the manual tungsten argon arc welding technology.

2021-10-22

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material