-

The Application of 3D Laser Scanning Metal Mine Goaf Survey

In the deep mining of mines, not only has high requirements for mining technology, but also poses a great threat to the safety of mining. In order to ensure the effective and safe operation of mining work, 3D laser scanning technology is used as an advanced measurement technology. , Has been gradually applied in mining. The article analyzes the application of three-dimensional laser scanning technology in the measurement of goafs in metal mines, and provides references for people in the same industry.

2021-08-14

-

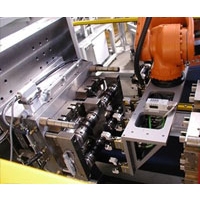

The Application Of Industrial Robot Machining Loading And Unloading

This article first introduces the composition, application significance and characteristics of industrial robot machining loading and unloading applications, and detailed analysis of the rigidity and accuracy of industrial robots in industrial robot machining loading and unloading applications, as well as the rapid recovery problems after collisions and failures. The problem is analyzed in detail and the key solving techniques are analyzed. Namely, terminal load automatic identification technology and dynamic torque feedforward technology, collision detection technology, zero point recovery technology, and finally the future development trend of human-machine collaboration and information fusion is proposed.

2021-08-21

-

Carbon Fiber Is Breakthrough Problem For Automobile Lightweight

If the next destination of automobile manufacturers is always faster speed, lower fuel consumption and less exhaust emissions, then lightening is a shortcut. As long as the weight of the car body is reduced, it will inevitably increase the speed, reduce energy consumption and reduce energy consumption. emission. In this shortcut, carbon fiber is an inaccessible bridge.

2021-10-02

-

The Reason Why Sheet Metal Parts Are Gradually Replaced By Thermoplastic Plastics

Sheet metal is a metal processing technology that performs a series of processing such as shearing, cutting, punching, and folding of metal sheets. Most of the processed materials are steel plates, and the processed products are widely used, especially in the automotive industry.

2021-09-18

-

How Accurate Is The 3D Printing Parts?

"What is the accuracy of your 3D printed parts?" This is a question often asked by 3D printing practitioners. So what is the accuracy of 3D printing? The answer to this question depends on many factors, the type of 3D printing technology, the status of the 3D printer and the settings of the printing parameters, the selected materials, the model design, etc.

2021-08-21

-

The Feature Extraction Method For Parts 3D Model

The premise of process design is the conversion of part information from design knowledge to process knowledge. In actual engineering, the design knowledge is included in the part 3D model and 2D drawings. In the process of conversion to process knowledge, the process designer needs to read the part 3D model and drawings. , Artificially acquire design knowledge and design corresponding processes.

2021-08-14

-

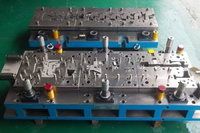

The Mold Parts Need Your Careful Maintenance

For the mold structure where the discharge spring is between the fixed plate and the discharge plate and the discharge spring is directly on the inner guide column, the disassembly of the discharge plate must ensure that the discharge plate is balanced and ejected. The tilt of the discharge plate may cause the punch in the mold to break

2021-10-09

-

The Origin And Characteristics Of Swiss Machine

Swiss Machine-the full name is the center-moving CNC lathe, it can also be called the headstock mobile CNC automatic lathe, the economical turning-milling compound machine tool or the slitting lathe. It is a precision processing equipment that can complete lathe, milling, drilling, boring, tapping, engraving and other compound processing at one time. It is mainly used for batch processing of precision hardware and shaft special-shaped non-standard parts.

2021-08-21

-

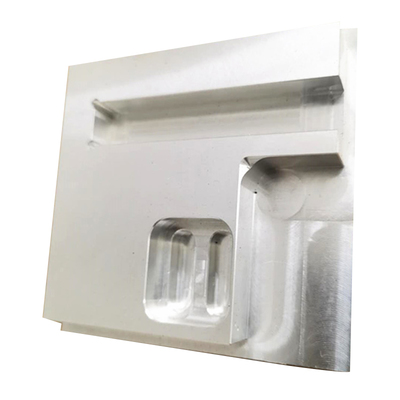

The Surface Treatment Technology Of Aluminum Alloy

Aluminum has many advantages such as low density, high specific strength, good corrosion resistance, high electrical and thermal conductivity, weldability, good plasticity, easy processing and forming, and excellent surface decoration properties. Aluminum alloy is made of pure aluminum by adding some alloying elements

2021-08-14

-

The Aerospace Parts Manufacturing Process Route Planning

The part contains several machining features, and each machining feature has several corresponding machining methods and manufacturing resources.

2021-08-21

-

What Factors Are Affecting The Tensile Test Of Metal Materials

Tensile test is the most common experiment in the mechanical property test of metal materials. It is said that the tensile test reflects the basic properties of the material, but the measurement results of the same material through different tensile test processes are not necessarily the same.

2021-10-20

-

The Exploration And Practice Of 6S Management Mode In Machining Training Teaching

Implement the 6S management mode in the mechanical and electrical professional machining training teaching of higher vocational colleges, organically combine knowledge, ability, and quality education, and integrate the training teaching with the actual production of modern enterprises, which can enable students to establish professional awareness and form good professional habits. , Possess excellent vocational skills to improve professional quality.

2021-08-14

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material