-

The Research On Mining Decision Rules Of Part Manufacturing Process

Process decision rule mining technology aims to mine the relationship between part feature parameters, processing methods, and manufacturing resources from historical process data, and store them in the corresponding database in the form of decision rules. In the process of process design, according to the part feature parameters Match the corresponding processing methods and manufacturing resources, and push them to the craftsman for reference.

2021-08-14

-

The Commonly Used CNC Machining Standards For Drawing Molds

Stretching die machining is an indispensable process equipment for stamping production, and it is a technology-intensive product. The complexity of the machining structure will inevitably lead to the complexity of the shape of the mold parts. The following explains the knowledge about the commonly used CNC standards for drawing mold machining.

2021-08-14

-

Advantages Of Finishing Agents In Additive Manufacturing: Smoothness, Compatibility, Adhesion

Initially, additive manufacturing (AM) was considered too slow or too expensive to be used in mass manufacturing. Many engineers only consider using it for part prototyping, fixture manufacturing, or low-volume operations. But recent advances in software and hardware technology mean lower costs and faster production speeds, making AM an attractive alternative, even for complex or high-volume production runs.

2021-10-02

-

The Cost Control And Optimization Of Cnc Machining Process

In the machining process, by controlling and optimizing industrial costs, the goal of saving production costs and improving the economic benefits of the enterprise can be achieved.

2021-08-28

-

The Current Status And Research Analysis Of CAPP Technology

Computer Aided Process Planning (Computer Aided Process Planning, CAPP) refers to the use of computer software and hardware technology and supporting environment, the use of computer numerical calculation, logical judgment and reasoning and other functions to formulate the machining process of parts. Using the CAPP system to complete relevant parameter calculations and generate process routes based on manufacturing information through human-computer interaction has an important role in reducing the labor intensity of staff, improving production efficiency, and improving product standardization.

2020-09-19

-

The Difference Between High Speed Steel And Tungsten Steel

High-speed steel (HSS) is a tool steel with high hardness, high wear resistance and high heat resistance, also known as wind steel or front steel, which means that it can be hardened even if it is cooled in the air during quenching, and it is very sharp. It is also called white steel.

2021-08-14

-

The Features And Operation Of Flat Welding And Vertical Welding

Flat welding refers to the welding process in which the welding place is at a horizontal position or at a small angle of inclination, the welding rod is located on the workpiece, and the welder looks down on the workpiece. This welding position belongs to the most easily welded position among all welding positions.

2021-10-16

-

Analysis of Difficulties in Machining Gray Cast Iron

The results show that the content of S and P of 26# pig iron was above the high side, the content of Si of 22# pig iron is low, so the chemical compositions do not satisfied criteria. The carbon equivalent of the castings is 4.36%, which is belonging to high carbon equivalent castings.

2021-08-21

-

The Significance Of Cnc Machining Spacecraft Shell

Significance of machining process design for typical shell parts of spacecraft. By establishing a machine-added process knowledge network model, mining process decision rules, and intelligently planning process routes, the reuse rate of process knowledge for typical shell parts of spacecraft can be increased to improve process design efficiency and quality.

2021-08-14

-

The Basic Knowledge Of Plaster Mold And Ceramic Modeling

Gypsum is generally white powdery crystals, as well as gray and reddish yellow crystals. It belongs to the monolithic crystal system. In terms of composition, it is divided into dihydrate gypsum and anhydrous gypsum. The ceramic industry mold production application is generally dihydrate gypsum.

2021-08-28

-

Performance of Metal Parts Printed by FDM 3D Printing

This article explores the performance characteristics of metal parts produced using FDM technology, addressing aspects such as mechanical properties, surface finish, dimensional accuracy, and potential applications.

2024-07-22

-

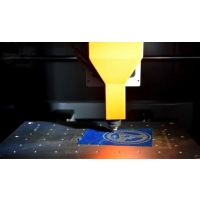

What Is Reflow Soldering?

Reflow soldering is to remelt the solder paste pre-distributed on the printed board pads to realize the mechanical and electrical connection between the solder ends or pins of the surface mount components and the printed board pads

2021-10-16

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

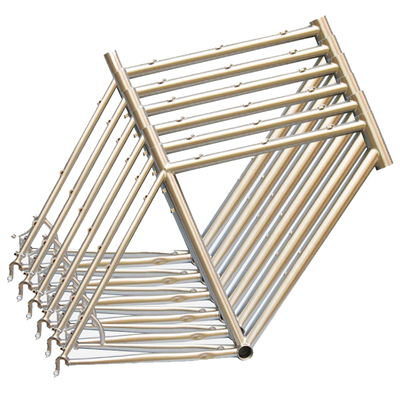

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material