-

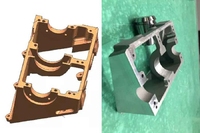

The Prototype System Development Of Aerospace Shell

Based on the previous theoretical research, and for the process design requirements of typical shell parts of spacecraft, in order to achieve the extraction of the manufacturing features of the parts, the feature extraction tool is designed based on the Siemens NX10.0 secondary development API.

2021-08-21

-

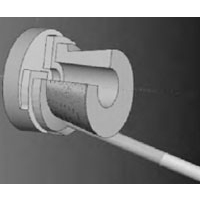

The Cnc Machining of Fan Injection Model Cavity And Core

It is the most tough and difficult task of the machining of the cavity and core during plastic mold manufacturing, which includes the CNC and EDM process. The CNC toolpath programming is the key task of the whole manufacturing process which determines the quality of CNC and the difficulty of EDM.

2021-08-27

-

What Is GR2 Titanium

GR2 titanium is a silver-white metal with a density of 4.5g/cm3 (20℃) and a melting point of 1668℃. Titanium and titanium alloy materials have the characteristics of good corrosion resistance, low density and high specific strength.

2020-06-13

-

Technology And Difficulties Of Casting Shell Body Analysis

From the comparison of the quality of precision castings, the water glass shell is inferior, followed by the composite shell, silica sol-low temperature wax shell, and silica sol-medium temperature wax shell is the best.

2021-10-16

-

Manufacturing Process Route Planning Based On Specific Immunity

At present, the process route planning of spacecraft shell parts still mainly relies on the experience of engineers, which cannot adapt to the "multi-type, small-batch" production mode, and there are problems such as low efficiency and uneven quality. Therefore, the research on the intelligent planning of the process route is very necessary.

2021-08-14

-

The Five-Axis CNC Machining Of Special-Shaped Bodies

Feasible five-axis controlled CNC machining of a special shape part was put forward. Firstly,the 3-dimension model was set up . Secondly,the machining policy and the tool track were planed. Then,VERICUT software was used to realise simulating cnc machining.

2021-08-21

-

What Is Hastelloy C-276

Hastelloy C-276 is a nickel-molybdenum-chromium-tungsten alloy with excellent corrosion resistance and good forging properties.

2020-05-15

-

Cnc Turning Case Studies Of Stainless Steel Low Temperature Ammonia Pump Slender Shaft

The turning of the stainless steel slender shaft of the low temperature ammonia pump uses the CY6140-B horizontal lathe to complete the turning of the stainless steel slender shaft of the ammonia pump in the coalification area of the ironworks, which meets the customer's requirements and ensures the normal operation of the equipment.

2021-10-09

-

The Characteristics Analysis Of Machining Surface Micro-Profiles

Taking the machining standard sample as the object, the difference in the surface roughness of different machining surfaces is studied, the characteristics of the surface topography obtained by different machining are analyzed, and the surface topography with different roughness obtained by the same machining method is observed.

2021-08-21

-

Talking About The Use Of Tungsten Steel In Forming Molds

The beam of the frame in the forming, forming inserts the general use of Cr12MoV,its surface is easy to generate "plot aneurysm clipping", leading to the beam and different surface stretch marks, reduce the carrying capacity of the beam, in order to solve this problem, through many experiments, we found thatthe tungsten steel applied to the die, but not avoid the sheet forming processand insert "adhesion", to solve the "plot aneurysm clipping" , and tungsten steel is not easy to wear, improve the stability and service life of the die, the surface quality of products.

2021-08-21

-

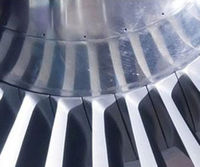

Titanium Alloy Material Grinding Skills

The machining of TC4 titanium alloy is very difficult. The comprehensive process of titanium and titanium alloy is very different from steel, aluminum alloy and many heavy metals in terms of crystal structure, physical properties and chemical properties. Alloy is a metal that is not easy to process.

2020-05-16

-

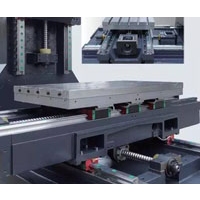

The Principles, Precision Influencing Factors And Optimization Measures Of CNC Lathes

At present, CNC lathe technology machining is the best choice for manufacturing production and machining. It can effectively ensure the economic benefits of the enterprise and improve the efficiency and pass rate of product production.

2021-10-09

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material