-

What Kind Of Machine Tool Is Suitable For CNC Upgrading And Remanufacturing

However, the purchase of new CNC machine tools, especially large CNC machine tools, is expensive, which often makes many users daunting. Especially developing countries like our country have limited funds. Therefore, most machinery factories want to buy but cannot afford CNC machine tools. How to obtain CNC machine tools with relatively little investment is a question worthy of discussion.

2021-10-09

-

The Cost Analysis Of Hot Stamping Process

At present, hot forming is divided into direct hot stamping and indirect hot stamping, as shown in Figure 1. In direct hot stamping, the semi-finished product is heated first, and then transferred to a closed mold for forming and quenching; indirect hot stamping mainly uses a pre-formed cold mold, and a cold-punched pre-formed part is first performed for parts with more complex shapes or deep drawing.

2021-10-23

-

[Processing Technology] Causes of metal hydrogen embrittlement and methods f removing hydrogen embrittlement

Hydrogen embrittlement is the polymerization of hydrogen dissolved in steel into hydrogen molecules, causing stress concentration, exceeding the strength limit of the steel, and forming small cracks in the steel, also known as white spots.

2021-10-23

-

Femtosecond Laser Cutting: Its Material And Application

Ultrafast lasers include picosecond and femtosecond lasers. Picosecond lasers are a technological upgrade of nanosecond lasers, and picosecond lasers use mode-locking technology, while nanosecond lasers use Q-switched technology.

2024-02-26

-

Numerical control machining of complex and special-shaped parts

If the production batch of special-shaped parts is large, then casting, forging or powder metallurgy can be used to reduce the manufacturing cost of the parts, but a large amount of mold costs are required in the early stage, and the mold trial production cycle is longer

2021-10-23

-

From Guns to Warships: CNC Machining in the Defense Industry

In the ever-evolving landscape of modern warfare, precision and efficiency have become paramount. One technology that has played a pivotal role in meeting these demands is Computer Numerical Control (CNC) machining.

2023-09-26

-

Using a reciprocating saw for pipe cutting helps improve safety, versatility, and ease of use

Grinding machines not only have a place in metal manufacturing, but are also suitable for finishing operations and cutting. The tools and cutting blades are reliable and can process all kinds of metals quickly.

2021-10-23

-

A Detailed Analysis of Hard Chrome Plating vs. Decorative Chrome Plating

Chrome plating is a widely used surface finishing technique that enhances the appearance and durability of various materials. Two common types of chrome plating are hard chrome plating and decorative chrome plating

2024-01-15

-

Precision Machining of High-precision Coaxial Holes in Titanium Alloy Camera Bracket

In the processing of titanium alloy camera brackets, a three-axis machine tool is used to cooperate with the turntable. By controlling the clamping deformation of the parts, the auxiliary alignment datum is added, the cutting tools are reasonably selected, and the deformation in the processing is reasonably controlled.

2021-10-23

-

Exploring the Top UV-Resistant Plastics for Superior Custom Manufacturing

In this article, we will delve into some of the best UV-resistant plastics available for custom manufacturing, providing insights into their features and applications.

2024-01-22

-

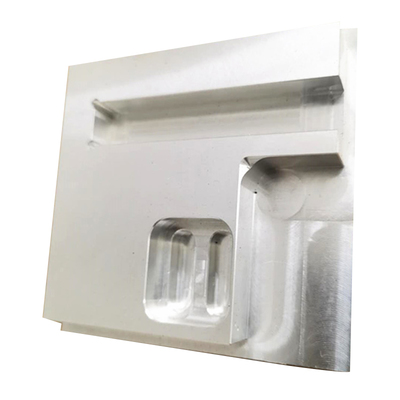

Fine-tuning the part design saves time and cost, what should I pay attention to?

Although the design of the part may meet all the correct functional requirements, it does not mean that the design is suitable for cost-effective CNC machining. In fact, some part features may be difficult or even impossible to process as designed, which will affect cost, quality and yield issues.

2021-10-23

-

Unveiling the Variances Between 1060 and 6061 Aluminum Sheets

In the vast world of metal alloys, aluminum stands as an indispensable component owing to its remarkable versatility and widespread utility across various industries.

2024-01-22

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material

![[Processing Technology] Causes of metal hydrogen embrittlement and methods f removing hydrogen embrittlement](upload/thumb/1634958846.jpg)