Femtosecond Laser Cutting: Its Material And Application

Ultrafast lasers include picosecond and femtosecond lasers. Picosecond lasers are a technological upgrade of nanosecond lasers, and picosecond lasers use mode-locking technology, while nanosecond lasers use Q-switched technology. Femtosecond technology uses a completely different technical route. The light emitted by the seed source is broadened by the pulse stretcher, amplified by the CPA power amplifier, and finally compressed by the pulse compressor to extract the light. The technology is more difficult.

When it comes to femtosecond laser, the first thing that comes to mind may be common uses such as femtosecond myopia correction and femtosecond freckle removal used in medical cosmetology. Femtosecond lasers are also divided into different wavelengths such as infrared, green light, and ultraviolet. Among them, infrared light Application areas have unique advantages: Infrared lasers can be selectively absorbed by materials or molecules and have almost no heat-affected zones in Laser Cutting in industries such as electronics, photonics or medical. Currently, it can be used in many fields such as materials precision laser cutting, surgery, consumer, electronic communications, spectroscopy, aerospace, defense applications and basic science. So this time we will introduce several typical applications of Be-Cu infrared femtosecond lasers in industry.

Laser Cutting Ultra-Thin Glass (UTG)

At present, ultra-thin glass materials have been widely used in consumer electronics displays and semiconductor industries. For example, the substrate glass in our commonly used OLED screens is ultra-thin glass (UTG).

With the continuous innovation of mobile phone technology, mobile phone screens are becoming younger and more diverse, and folding screen technology emerged as the times require. However, folding screen mobile phones have very high requirements for glass. The thinner the glass, the better the light transmission performance, the better flexibility, and the lighter the weight. However, this type of electronic glass Laser Cutting requires high precision, high efficiency, no micro-cracks, no dark cracks, etc. Therefore, ultra-fast Laser Cutting of electronic glass has become the main Laser Cutting method at present, and as our requirements for edge chipping and micro-cracks increase, , femtosecond laser has gradually become the best choice.

Femtosecond laser cutting has ultra-high energy density and can easily exceed the glass damage threshold; at the same time, ultra-thin glass is more sensitive to heat, and femtosecond pulse is a "cold Laser Cutting" mode, which can make the edge of the light spot complete, the light spots do not interfere with each other, and achieve ultra-low fracture Effect: During the Laser Cutting process, the side wall can be made smooth, irregular chipping is less likely to occur, and abnormal cracks caused by excess heat are less likely to occur. It has no impact on the UTG bending radius and can maximize the bending life.

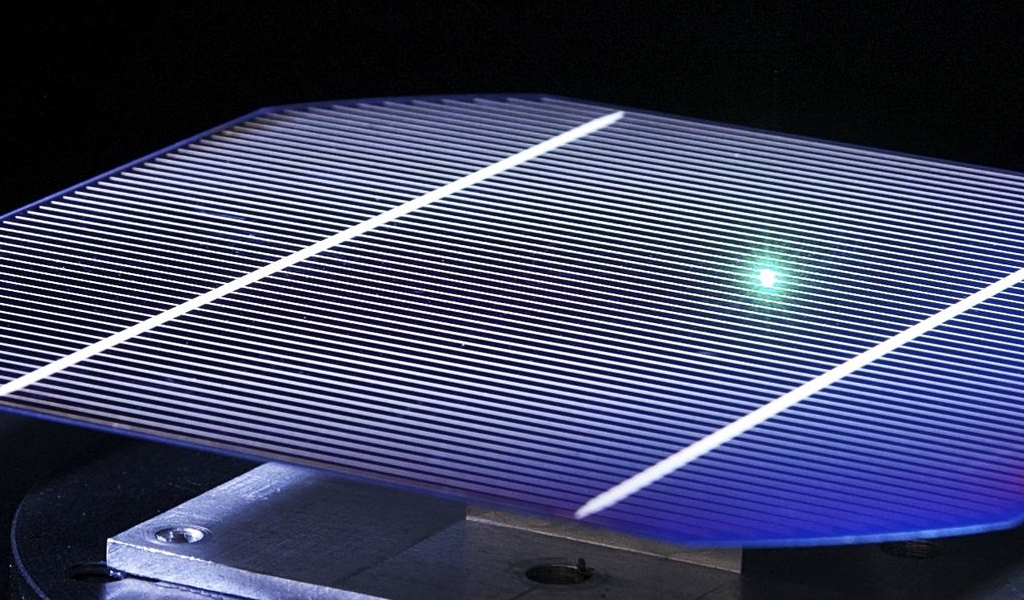

Laser Cutting Gold-Plated Copper Foil

Copper foil is one of the commonly used components in the electronics industry. The electrolyte is a negative electrolyte that is deposited in a layer on the circuit board substrate and serves as the circuit board's electrical conductor. Copper foil is a very thin copper product. Copper is the same as paper and its thickness is also microns. Usually 5um-135um, the thinner and wider the harder it is to make. Simply put, copper foil is pressed into very thin sheets.

Copper foil is widely used in all aspects, such as electric vehicles, consumer electronics, aerospace, communication equipment and other fields. The traditional Laser Cutting method is mainly die-cutting, but there are deficiencies in efficiency, Laser Cutting speed, loss and cutting accuracy. When using ordinary laser cutting, the thermal effect is large. The thermal effect on the edges makes the copper foil easy to warp and deform, and the edges are carbonized, leading to material degeneration.

The femtosecond laser has more obvious advantages in Laser Cutting copper foil due to its unique "cold Laser Cutting" mode. Femtosecond laser has a narrower pulse width, which can process the material with very little thermal effect, avoiding damage to the material caused by heat accumulation, and well protecting the gold-plated layer from falling off;

During the direct cutting process, there will be no discoloration, no melting, no material contamination, etc.; and the femtosecond laser has excellent beam quality output. After focusing, it can ensure the consistency of the edge effect of the processed material and the cutting path. , the flatness on both sides of the end face enables truly precise cutting; it also supports multiple burst and pulse editing functions, further improving the Laser Cutting efficiency and effect.

Laser Cutting Zirconia Ceramics

In terms of ceramics, zirconia (YSZ) ceramic substrates have excellent high temperature resistance and can be used as induction heating tubes, refractory materials, and heating elements. And it has sensitive electrical performance parameters, high toughness, high flexural strength and high wear resistance, excellent thermal insulation properties, thermal expansion coefficient and other advantages close to steel. It is mainly used in ceramic knives, oxygen sensors, thermal substrates for fuel cells, Solid oxide fuel cells and high-temperature heating elements, etc.

Compared with metals, zirconia ceramics have the advantages of better wear resistance, smooth surface, good texture, and no oxidation. Many well-known high-end brands have also launched high-end ceramic watches, occupying a place in the smart wear field; ceramic ferrules and sleeves are also widely used in the field of optical fiber connectors; at the same time, zirconia ceramics have no signal shielding, are anti-drop, wear-resistant, and It has the advantages of folding, warm and smooth appearance, and good hand feel, and is widely used in 3C electronic fields such as mobile phones. However, during the Laser Cutting of traditional zirconia ceramics, there are inevitably a series of problems such as poor Laser Cutting quality and low Laser Cutting efficiency. This requires the use of femtosecond Laser Cutting, which can solve this problem more precisely and efficiently.

Due to the high energy peak of femtosecond pulses, cold Laser Cutting mode can be realized, which can better meet the strict requirements of products. During product Laser Cutting, femtosecond laser consumes less energy and causes less damage to materials, so the Laser Cutting accuracy is high; non-traditional Mechanical contact Laser Cutting is stress-free and evenly distributed at the edge of the sample. Ceramic chipping is less likely to occur in the melted state and the quality is better. The femtosecond laser has extremely high energy density during the Laser Cutting process and can achieve more efficient cutting capabilities for zirconia ceramic materials. , capable of quickly cutting material structures into shape.

More and more experimental applications are proving the major advantages of femtosecond Laser Cutting technology(with stent and hypotube laser cutting) in the industrial field. Be-Cu is also constantly cultivating it, increasing application experimental operations to give full play to more femtosecond advantages and continue to provide The transformation and upgrading of advanced manufacturing industries lays a solid foundation and promotes development.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material