-

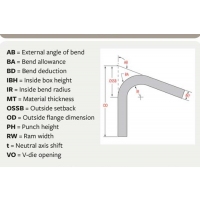

How to eliminate waste on the bending machine?

Bending is the most complicated operation in metal manufacturing, and good communication is definitely the key. In this case, as in many other cases, engineers and operators may not have as much discussion as they did before the work was officially put into production.

2021-10-29

-

Is the poor effect of the bending machine related to the material?

Despite purchasing a new bending machine, we still encountered problems, such as being unable to maintain repeated angles. Our tool is a new tool, and precision drilling really helps us shorten the installation time. But achieving a consistent angle is a headache.

2021-10-29

-

What should I pay attention to when performing the bending process on a modern bending machine?

If you walked into the bending machine department of a manufacturer 20 years ago, you would see a very different picture. A machine produces a variety of new, low-quality jobs in a shift, but it takes most of the time to set up, and in fact there is very little time to bend good parts.

2021-10-29

-

What should be paid attention to in material preparation before welding?

The welding process is a very important step in various manufacturing processes. Weld all different types of metals for many different types of manufacturing. However, in order for any welding process to be accurate and effective at the first time, the parent material must be properly prepared.

2021-10-29

-

What are the benefits of automatic deburring?

New technologies in the manufacturing industry provide metal manufacturers with more options for producing parts for their customers. In particular, fiber laser cutting machines enable manufacturers to cut more parts a day than CO2 laser cutting. The automatic loading and unloading system connected to these laser cutting machines also enables the workshop to work 24 hours a day.

2021-10-29

-

What are the ways to achieve a specific metal finish?

The surface of the part may require a specific metal surface treatment for a variety of reasons, whether it is appearance, product function, or customer preference. Certain metal finishes can also help the material resist damage or rust.

2021-10-29

-

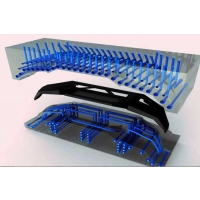

Metal additive manufacturing reduces costs and saves time for creating large parts

Metal manufacturing is subtractive in nature. In processes such as cutting, grinding, and drilling, part of the basic material becomes waste, which requires a system for waste treatment, disposal, and possible recycling.

2021-10-29

-

How do electroplating manufacturers choose between sulfate and trivalent chromium chloride?

Decorative electroplaters in the automotive industry finally decided to transition from hexavalent chromium electroplating to trivalent chromium electroplating. There is a difference between a sulfate bath and a chloride bath, so what is the difference between the two? What factors might we consider when evaluating options?

2021-10-29

-

The development and opportunities of sheet metal forming technology

With the development of new materials and technologies for sheet metal forming, the industry needs to challenge the status quo. With the reduction of skilled labor, we need to learn as much new technology as possible, share information with each other; and develop innovative and encouraging workplaces that support new talents.

2021-10-29

-

10 ways 3D printing drives plastic manufacturing

In some applications, 3D printing cannot be touched, and may never be touched. For example, for production runs of thousands of parts, the choice of 3D printing plastic components cannot compete with the speed and efficiency of existing processes (such as injection molding).

2021-10-29

-

Explain the first process of extruded aluminum processing technology-casting

With the development of science and technology, all walks of life have higher and higher requirements for the quality of metal products, and more and more attention is paid to the metal smelting process.

2021-10-29

-

Different surface treatment and performance comparison of aluminum alloy profiles

The colors of powder spraying and fluorocarbon spraying paint are diverse, while the color of electrophoretic paint is relatively monotonous, generally only the color of anodized oxidation in the past. On the surface, electrophoretic coating and fluorocarbon spray paint are much smoother than powder spraying, while electrophoretic coating maintains the stripes of the aluminum profile itself and can better reflect the true color of aluminum. Powder sprayed fluorocarbon spray paint completely covers the aluminum Matrix.

2021-10-09

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material