-

How does the axle affect the performance of a precision grinder?

Precision grinding operations cover all applications that require tight tolerances on dimensions and low Ra surface finish requirements, including cylindrical external grinding (OD), internal grinding (ID), surface grinding and creep grinding. The grinding wheels used for these operations are usually conventional alumina grinding wheels or ceramic grinding wheels with different shapes and sizes, but depending on the application, super-ground diamond and cBN grinding wheels can also be used.

2021-11-01

-

What are the methods of deburring and finishing operations?

Deburring and finishing of processed and manufactured parts are essential steps in the manufacturing process, but they are often overlooked. As a result, some stores still handle this task as they did in the last century, relying on manual deburring and polishing methods instead of using more modern, automated, and predictable methods.

2021-11-01

-

What are the advantages of the new grinding technology over traditional machining?

Although the development of machining centers has improved the ability to operate in large quantities, there are still some products that need to be ground. Compared with conventional machining, grinding has many advantages, including longer tool life, finer surface finish, and the ability to more effectively remove difficult-to-machine materials (such as new ceramic composite materials and metal alloys impregnated with carbides) .

2021-11-01

-

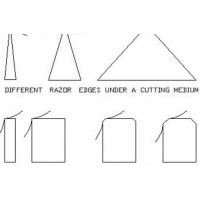

Metal manufacturers must make these preparations to reduce the risk factor of sheet metal edges

To determine the sharpness of sheet metal edges, metal manufacturers must be prepared in the design stage. Whether in sharp products or non-sharp products, there are very few modern standards to define clarity. Manufacturers usually use several standards or proprietary standards, but it is difficult to find a balanced, cost-effective way to deal with clarity.

2021-11-01

-

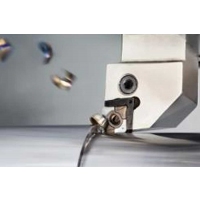

Use chip breaking solutions to effectively cut low- and medium-carbon alloys

Low-carbon and medium-carbon steel almost constitute the main products of every workshop in its general engineering applications and manufactured parts.

2021-11-01

-

Expertise in post-processing is essential to meet customer expectations of 3D printed parts

Apart from 3D printing, what makes additive manufacturing unique are all the processes performed. AM first designs parts dedicated to additives, then programs them, optimizes the process, prints the parts, and finally post-processes them.

2021-11-01

-

What should be paid attention to in electroplating?

Manufacturers designing piping components or components need to adopt anti-corrosion strategies to protect their products and reputation. They have several options for obtaining corrosion resistance: they can specify the manufacturer to use corrosion-resistant metal or use paint or powder coating, or they can specify that the metal should be plated.

2021-11-01

-

7 tips for finishing stainless steel

In order to obtain the most common stainless steel coatings, you usually have to perform many steps in a specific order. Because stainless steel is more susceptible to heat and contamination, you may find that using this material is more time-consuming and expensive than using carbon steel.

2021-11-01

-

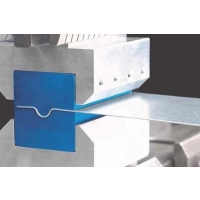

3D printing tools can make low-tonnage bending machines more flexible

Small and light bending machines are usually electric or hydraulic-electric hybrid. A few years ago, considering the low tonnage and bed length, the store may have abandoned them. After all, why invest in a machine that can only handle small parts in a workshop?

2021-11-01

-

Analysis of basic precautions for laser welding

In every industry, products are being designed, redesigned or re-evaluated to obtain better materials or functions. The final product consists of many components, which need to be combined in some way. One of these connection methods is laser welding.

2021-11-01

-

Avoid the difference in the sheet metal bending process

There are often some errors in the sheet metal bending process, so how to avoid it?

2021-11-01

-

The 20-year Working Experience Sharing Of Mold Engineer

The problem is that China's mold industry mainly processes low-end to mid-range molds. There are not many high-end molds. I believe that in the near future, China's rise will be unstoppable, and the transformation of manufacturing industry will also be unstoppable. The same is true for our mold industry. . After all, it is impossible to make first-class products without first-class molds.

2021-10-09

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material