-

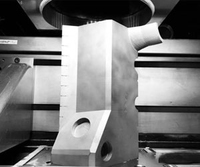

Research on Efficient Cleaning Equipment and Technology of Resin Sand Core

The core was cleaned by dissolving vibration by Ding Yi, and the effects of different NaOH solution concentration, excitation force and core heating temperature on the cleaning efficiency of dissolving vibration were studied.

2021-11-30

-

How To Make A Surgical Mask?Classification of mask machine

PTJ Shop has customers who specialize in making mask machines, and PTJ Shop provides them with cnc machining of precision mask machine parts.Serviced Face mask blank making machine,Mask outside earloop welding machine,Fliter face mask making machine,Duckbill face mask making machine etc.,

2020-03-21

-

High-strength&ductile stainless steel parts can be produced

Recently, a joint research team from the University of Birmingham in the United Kingdom, Stockholm University in Sweden and Zhejiang University in China developed a new stainless steel SLM 3D printing technology with high strength and ductility, which overcomes the strength and ductility of additive manufacturing. The bottleneck. This process can be used to manufacture heavy components in the aerospace and automotive industries.

2019-09-24

-

Twenty of the most promising new materials in the future world

The material industry is the basic industry of the national economy. The new materials are the forerunners in the development of the materials industry and an important strategic emerging industry.

2019-09-14

-

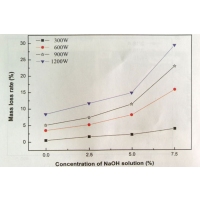

Research on Dissolving Ultrasonic Cleaning Process

The core is cleaned by the cleaning process of dissolving ultrasonic wave, and the influence of different NaOH solution concentration, ultrasonic power and core heating temperature on the efficiency of dissolving ultrasonic cleaning is studied.

2021-11-30

-

Model Classification Of Pipe Thread Lathe

Pipe thread lathes are mainly divided into ordinary pipe thread lathes and CNC pipe thread lathes according to different control and operation methods.

2020-01-18

-

Supply Warm Cnc Machining Service To Malaysian customers

PTJ Shop is a great local machine shop. They have a wide range of capabilities from milling, turning, EDM, assembly, and more. They are well suited for just about any project including high-volume jobs because of their production cell. Great group to work with all around! Talk to David or Michelle.

2019-12-14

-

Can magnesium alloy die castings be popular in automotive lightweighting?

The lightweight of the car is to “slim down” the car, and on the basis of ensuring stable and improved performance, energy-saving design of various components and continuous optimization of the model. The experiment proves that if the weight of the whole vehicle is reduced by 10%, the fuel efficiency can be increased by 6%~8%; the weight of the car is reduced by 1%, the fuel consumption can be reduced by 0.7%; for every 100 kilograms of the car's whole weight, the fuel consumption per 100 kilometers can be reduced by 0.3~0.6. Rise.

2019-09-28

-

Hot pressing post-treatment 3D printing continuous carbon fiber reinforced thermoplastic

Although the classical fused deposition molding process (FDM) has inherent advantages in the manufacture of complex structural parts, the components manufactured using this technology still have problems of insufficient strength and low heat resistance.

2019-09-21

-

The stability and consistency of the quality of cast iron production technology in china

In the production of cast iron in my country, the stability and poor consistency of quality are an old problem, which is mainly reflected in the large fluctuations in the chemical composition and mechanical properties of the material, and the defects of the castings cannot be completely eliminated.

2021-11-30

-

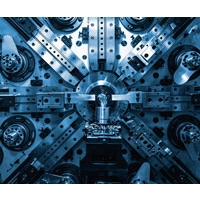

4 Kinds Main Applications Of High-End CNC Machine

Through in-depth on-site investigations and communication between industry users, we have a clearer understanding of the development of these user industries, the characteristics of typical parts, and the requirements for equipment.

2021-08-14

-

Israel Toolings GB and Machine Director Corning arrives at PTJ Cnc Machining Factory

We’ve used PTJ Shop sporadically over the course of 10 years and have never had major issue with them. They’re always timely and responsive. The one time when we did have a small problem they made good on their promise and remade all the parts. They’re a great supplier to Toolings GB.

2019-12-14

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material