The basic knowledge of worm gear machining

2019-11-16

Worm gear machining basics

| The worm gear is a gear that meshes with the worm and has a special tooth shape. The cutting process of the worm gear tooth is generally completed by a hobbing machine, mainly including two methods of hobbing and flying cutter cutting. |

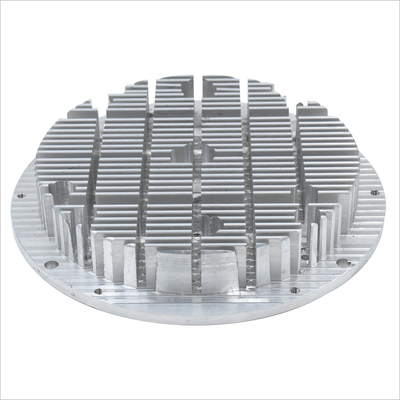

Worm gear machining

When manufacturing precision worm gears, it is possible to perform finishing such as shaving, squeegee or grinding after hobbing or cutting.

Hobbing:

The worm gear hob with the same basic parameters as the working worm is used, and the tooth profile is cut according to the principle of the forming method. If the hobbing method of the radial feed method is adopted, the ratio of the hob to the workpiece according to Z2/Z1 (Z1 is the number of working worm thread heads, Z2 is the number of worm gear teeth), and the two are gradually approached until the center distance is equal to the working worm. The center distance when meshing with the worm wheel. When hobbing is performed by the tangential feed method, the machine tool must have axial feed in addition to ensuring the rotation of the tool. At the same time, the machine table must also increase the corresponding additional rotation to realize the development movement. chain. Therefore, the machining accuracy of the tangential feed method is generally not as good as the radial feed method, but the tooth surface quality is good and no undercut phenomenon occurs. The accuracy of the hobbing worm gear is generally 6 to 8 (JB162-60).The hobbing of the precision worm gear needs to be carried out on a high-precision indexing worm gear hobbing machine with a high-precision hob. Mechanical or electronic transmission chain error correction devices can also be added to the universal gear hobbing machine to improve machining accuracy and maximum machining accuracy. Up to level 3.

Flying knife

The flying knife is equivalent to one tooth of the worm wheel hob. The flying knife can only use the tangential feeding method. On the hobbing machine, the flying knife can be turned into a worm wheel for Z1 teeth, and the tangential feeding of the flying knife and the additional rotation of the table can also be performed according to the expansion method. The principle cuts out the correct tooth shape, and the precision can reach 7-8. The flying knife is simple to manufacture, but the cutting gear has low productivity and is suitable for use in single piece production and repair work.Shaving

The basic parameters of the worm gear shaver are the same as those of the working worm. The worm gear shaving is generally carried out by a hobbing machine. The worm wheel can be freely shaved by the shaving cutter, and the shaving can be forced under the control of the machine tool transmission chain. The quality and precision of the shaving tooth surface are improved.Dental caries and teeth

After the worm gear hobbing or the flying knife cutting, in order to improve the quality of the tooth surface and improve the contact between the worm wheel and the worm, the hobbing machine can grind or grind the tooth. The caries tool is a honing worm made by casting a mixture of abrasive and plastic and resin on a substrate; the grinding worm made of cast iron with grinding abrasive and worm wheel is ground.Link to this article: The basic knowledge of worm gear machining

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Our Services

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

Case Studies

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

Material List

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material

Parts Gallery