3D printing helps miniaturize ultra-cold quantum experiments

How to find some of the coldest objects in the universe, you may not need to go very far. There, physicists may be using lasers and magnets to cool atoms to an astonishing degree below 450 degrees Fahrenheit. They may use these ultra-cold atoms to sense the weakest magnetic field in the room, or build a clock accurate to a quadrillionth of a second. But they may not be able to take these sensors or clocks out of the laboratory because they are often large and fragile.

Now, a team of physicists at the University of Nottingham has demonstrated that the 3D printed parts used in these ultra-cold quantum experiments allow them to shrink the device to a third of its usual size. Their work, published in the journal Physical Review X Quantum in August, can open the door to faster and more convenient methods and make smaller, more stable, and customized settings for experiments.

Because they obey the rules of quantum mechanics, extremely cold atoms exhibit new useful behaviors. Ultra-cold atoms are a key technology that can be used in many different precision instruments. John Kitching, a physicist at the National Institute of Standards and Technology in the United States, said he was not involved in this research.

Ultra-cold atoms are excellent time sensors. They are excellent sensors of what we call inertial forces, therefore acceleration and rotation. They are excellent magnetic field sensors. They are excellent vacuum sensors, and his colleague Stephen Eckel added that he was not involved in the work either.

Therefore, physicists have long sought to use ultra-cold atomic devices in space exploration. In space exploration, they can help navigation by sensing changes in vehicle acceleration, to hydrology, where they can detect ground The gravitational force on the ground can accurately locate the groundwater. However, the process of getting atoms cold enough to take on any of these tasks is often complicated and arduous. As a cold atom experimenter, I have always been frustrated because we spend all our time solving technical problems. Nathan Cooper, a physicist at the University of Nottingham and one of the co-authors of the study. Say.

The key to cooling and controlling the atoms is to irradiate them with a fine-tuned laser. Warm atoms move fast at hundreds of miles per hour, while extremely cold atoms are almost stationary. Physicists ensure that every time a laser beam hits a warm atom, the light hits it in such a way that the atom loses some energy, slows its speed, and becomes colder. Usually, they work on a 5 x 8 foot table, covered with a labyrinth of mirrors and lenses (optical elements), when the light hits millions of atoms (usually rubidium or sodium), they will To guide and manipulate light, these atoms are stored in a special ultra-high vacuum chamber. To control the position of all the ultra-cold atoms in this room, physicists use magnets; their fields are like fences.

These experimental devices are small compared to miles of particle accelerators or large telescopes. However, they are too large and too fragile to be a commercial device for use outside of academic laboratories. Physicists often spend months aligning every small element in their optical maze. Even slight shaking of the mirror and lens-which is likely to happen on site-will mean serious work delays. What we want to try and do is to build something that can be produced quickly and is expected to run reliably, Cooper said. Therefore, he and his collaborators turned to 3D printing.

The Nottingham team’s experiment did not take up the entire table—it has a volume of 0.15 cubic meters, which is slightly larger than a stack of 10 large pizza boxes. It is very very small. Compared with the traditional setup, we have reduced the size by about 70%, says Somaya Madkhaly, a graduate student in Nottingham and the first author of the study. To build it, she and her colleagues participated in a very customizable Lego game. Instead of buying parts, they assemble their set up with 3D printed blocks that fit exactly the shape they want.

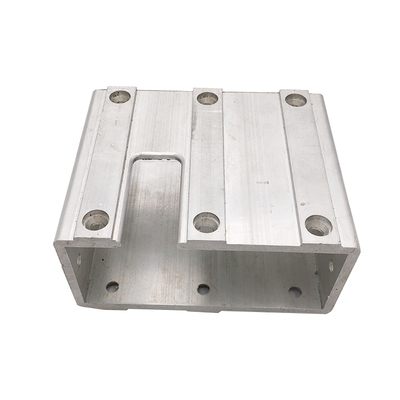

Instead of processing the vacuum chamber with a strong but heavy metal, the team printed it with a lighter aluminum alloy. Instead of building a huge maze of lenses and mirrors, they inserted them into a bracket printed with polymer. This rectangular part is only 5 inches long and 4 inches wide, and is very strong, replacing the delicate optical labyrinth that is usually several feet long.

The important thing is that the miniaturized setup worked. The team packed 200 million rubidium atoms into their vacuum chamber and passed the laser through all optical components, causing the light to collide with the atoms. The temperature of the sample formed by the atoms is below-450 degrees Fahrenheit-as scientists have done with more traditional equipment for the past 30 years.

Dinkelaker pointed out that one of the great benefits of using 3D printing is that you can custom design each component. Sometimes you only have a weirdly shaped widget or a weirdly shaped space. Here, 3D printing may be a good solution," she said.

Lucia Hackermuller, another co-author of the paper, stated that making each piece according to their own specifications allows them to optimize. We want the best design, but the problem is that we usually have construction restrictions, she said, but if you use 3D printing, you can basically print anything you can think of. As part of the optimization process, the team used a computer algorithm they developed to find the best position of the magnet. They also carried out about 10 iterations of the 3D printed components until they were completely exquisite.

This new research is an advancement in making this tool for basic physics research more affordable and accessible. Cooper said, I hope this will speed up standard ultra-cold atomic experiments and democratize them to a certain extent, making them cheaper and faster to install. He speculated that if he were trapped on a desert island with only a few lenses and mirrors, rubidium atoms and a 3D printer, he could go from zero to a fully functional device in about a month — five or six times faster than usual. For Madkhaly, starting from scratch may be more than an imaginary scene. She said that after graduation, she might return to her native Saudi Arabia to use 3D printing to start a new ultra-cold atom research. This is a very new field, she added.

Kitching also envisions that these tools will be used outside of academia, for example by companies that make quantum-driven sensors that can pick up magnetic or gravitational fields. These companies may not hire scientists trained in quantum physics, but it doesn't matter. He imagined that they would build assembly lines where technicians would assemble equipment with 3D printed components. If these devices are stable enough to operate without constant adjustments, employees can still use them with confidence.

For example, civil engineers, oil and gas companies, archaeologists, or volcanologists can use commercial ultra-cold atomic devices to better map underground topography based on the extreme sensitivity of atoms to gravity. Ultracold atomic clocks might be used to synchronize transportation or telecommunication networks, or to secure financial transactions in situations when every exchange or trade requires a very precise timestamp.

Hackermueller and her colleagues also plan to continue to optimize their existing settings. We believe that we have not fully utilized all 3D printing capabilities. This means that our setup can be smaller, she said-they think they can reduce it to nearly half its current size. Cooper said, we will see what the limits of what you can do with it.

Link to this article: 3D printing helps miniaturize ultra-cold quantum experiments

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material