Global production capacity and types of ABS resin

Acrylonitrile-butadiene-styrene resin (abbreviated as ABS resin) is widely used in household appliances, office equipment, auto parts, instruments, building materials and daily necessities. ABS resin is often blended with other different polymers into alloys to obtain the best performance. The basic raw materials of the ABS industry chain are oil and coal. Among the next terminal products, the two major industries of home appliances and automobiles are important, and there are many types of enterprises involved.

1. Global market situation

From 2010 to 2019, with the closure of parts of North America (due to the closure of SABIC Plastics plants) and Western Europe, new production capacity appeared in Northeast Asia, the Middle East, and India and Pakistan. The annual compound growth rate of global ABS production capacity was less than 2%. In 2019, the global ABS production capacity reached 11.45 million tons/year, the output was 9.65 million tons, and the average device load was 84%.

In 2019, the global ABS supply was mainly concentrated in Asia, which accounted for 83% of the world's production capacity. Among them, China's production capacity accounted for 37% of the global production capacity, South Korea and Taiwan, China each accounted for 17%.

From 2010 to 2019, affected by factors such as the once weak economy of developed economies, the average annual growth rate of global ABS demand was only 2.6%. In 2019, global ABS resin consumption reached 9.65 million tons, of which consumption in Asia accounted for about 79% of the world's total, and China and India are the main countries driving the growth of global ABS resin demand. In the global consumption of ABS resin, household appliances and electrical appliances account for 66%, and transportation, construction, and other fields together account for 34%.

In the past 10 years, the global ABS resin industry has slowed its capacity growth due to oversupply. However, with the steady growth of consumption, by 2019, the global ABS resin market has changed from an oversupply to a balance between supply and demand.

2. Domestic market analysis

2.1 Analysis of domestic ABS resin consumption

From 2010 to 2019, the average annual compound growth rate of domestic ABS resin consumption is about 4.3% (of which, 2010-2015 is 0.8%; 2015-2019 is 8.6%). In 2019, my country's ABS consumption achieved steady growth, reaching 6.05 million tons.

my country's ABS resin consumption structure in 2019 is: household appliances and electronic products accounted for 60%; light industrial products accounted for 11%, transportation accounted for 10%, office equipment 9%, and building materials and other 10%.

Home appliances and electronic products include major appliances, small home appliances and electronic products, which together account for 60% of the total domestic consumption. Among them, home appliances are the main ones. The consumption of ABS resin in consumer electronic products is relatively low. ABS resin-applied home appliances are mainly white home appliances and small home appliances. White home appliances are mainly air conditioners, refrigerators, and washing machines. There are many types of small home appliances, including microwave ovens, rice cookers, food processors, dishwashers, disinfection cabinets, and drinking water. Machines, water purifiers, sweeping robots, vacuum cleaners, audio systems, toasters, coffee machines, toasters, hair dryers, electric shavers, etc. ABS is mainly used in the shells of home appliances, control panels, and some decorative parts and parts. Electronic products for ABS include mobile phones, chargers and various digital products. In recent years, the demand for ABS resin in the market of small home appliances has quietly increased, and it is on par with major appliances. my country is the world’s largest producer and consumer of home appliances. In 2019, my country’s output of refrigerators and washing machines accounted for more than 50% of the world’s total, and air conditioners and microwave ovens accounted for 3/4 of the world’s output; home appliance exports accounted for more than 37% of the global export market. Exports of large household appliances accounted for 31% of the global share, and exports of small household appliances accounted for 45% of the global share. In 2019, my country’s output of air conditioners was 21.862 million units, a year-on-year increase of 6.7%; the output of refrigerators was 79.043 million units, a year-on-year decrease of 1.1%; the output of washing machines was 74.33 million units, a year-on-year increase of 3.9%.

In the field of transportation, ABS resin is mainly used in automobile dashboards, wheel covers, radiator grilles, air conditioners, trunks, handles, interior trim panels, steering wheels, sound insulation panels, door locks, ventilation ducts and other components and vehicles. In terms of items, it is also used for motorcycles, game vehicles, boats and snowmobiles. At present, my country has become the largest automobile producer in the world. In 2019, my country's auto production reached 25.721 million, a year-on-year decrease of 7.5%, which is another decline after 2018. Although China's auto production and sales continued to rank first in the world, the Chinese auto market in 2019 is still in a cold winter. Due to the decline in automobile production, the proportion of ABS resin consumption in the automotive sector in 2019 has dropped to 10%, and the home appliance sector and other sectors have increased. The development of new energy vehicles has promoted the growth of ABS resin consumption in the automotive sector.

In the field of light industrial supplies, ABS resin is mainly used in luggage, toys, lighters, etc. China is a major producer and exporter of toys and luggage in the world. Among them, electronic game consoles, toy musical instruments, toy models, etc. all use ABS resin in large quantities.

In addition, electronic computers, office automation equipment and communication equipment are also areas where ABS resin consumption is relatively large. The main products are computers, fax machines, copiers, printers, telephones, routers, etc. With its excellent properties, ABS resin is also used in the building materials market, mechanical instrument industry, medical equipment, alloy blends and other industries. In the building materials market, ABS resin is mainly used for pipes and decorative panels. Pipes include water supply pipes, drainage pipes and low-foaming pipes. Decorative panels are mainly used in office buildings, hotels, bathrooms, swimming pools, door frames, window frames and other fields. The popularity of leisure products such as yachts and mobile homes has also opened up new sales channels for the ABS market.

The increase in demand for ABS resin is not only closely related to the organic growth of downstream industries, but also related to the price trend and degree of substitution of the alternative product HIPS. Overall, it is estimated that in the next 5 years, the average annual growth rate of domestic ABS resin demand will be about 3%-5%.

2.2 Analysis of domestic ABS resin supply

my country is the largest producer of ABS resin in the world. In 2019, the production capacity and output of my country's ABS resin were 4.2 million tons/year and 4.05 million tons, respectively, and the industry average operating rate was about 96%.

From 2010 to 2019, the average annual growth rate of my country's ABS resin production capacity was 5.5%; the average annual growth rate of output was 7.8%, and the output growth rate was greater than the production capacity growth rate. In 2015, the average operating rate of my country's ABS resin industry was about 72%, and by 2019, the average operating rate of the industry will reach 96%. With the rapid growth of demand for ABS resin in my country, the ABS industry has moved from oversupply to a relatively tight supply.

Driven by the steady and rapid growth of ABS resin demand and good profitability, my country's ABS resin industry has entered a peak investment period in the past two years, and a large number of new ABS resin projects have emerged, such as Zhangzhou Chimei Chemical, Sinochem International, LG Chemical , Ineos, etc. (see Table 1 for details), the total production capacity of planned investment projects is estimated to reach nearly 4.4 million tons/year. Moreover, in addition, there are companies intending to invest in ABS resin, but due to difficulties in technology sources and funds, they did not start. Therefore, the production capacity of my country's ABS resin will increase substantially in the future. The new supply will not only meet the increasing domestic demand, but will even replace some imports, and some products will be exported.

3. Types of ABS

ABS is also divided into many types, such as electroplating grade, high impact grade, heat resistance grade and so on. Different types of ABS are polymerized into different types of ABS by adjusting the ratio of acrylonitrile, butadiene, and styrene. Acrylonitrile determines the material's aging resistance, chemical resistance and other properties; butadiene determines the material's impact resistance and low temperature characteristics; styrene determines the material's processability, fluidity and gloss.

Flame-retardant ABS

Since ABS itself is not flame-retardant, it is necessary to add a certain proportion of flame-retardant to ABS to achieve the flame-retardant effect. Most of the flame retardants added are halogen flame retardants. At present, most of the flame retardant ABS materials on the market are tetrabromo flame retardant additives, and a small part of ABS additives are tribromo flame retardants. Its flame retardant performance is comparable Tetrabromine flame retardant is more superior. At present, some petrochemical plants are developing materials between tetrabromo flame retardant and tribromo flame retardant.

Flame-retardant ABS is generally used in electronic and electrical products, such as display shells, TV series shells, router shells, power switchable panels, power sockets, car battery shells, POS machine shells, electric meter shells, printer shells, etc., and others in contact with power sources The product.

Heat-resistant ABS

Heat-resistant ABS is mainly to add heat-resistant agent to general ABS or choose heat-resistant AS. Usually, the modification plant adds heat-resistant agent. Large petrochemical plants will first make AS and then add rubber to synthesize heat-resistant ABS. Compared with general ABS, heat-resistant ABS has a higher heat distortion temperature (HDT) and a higher Vicat softening point. Its excellent thermal stability, good processability and coating properties can replace PC+ABS, and some Heat-resistant ABS can be used as electroplating products.

Heat-resistant ABS is used in microwave ovens, electric kettles, electric irons, hair dryers, coffee makers, car air-conditioning vents, car dashboards, car rearview mirrors and other products.

Electroplating ABS

Electroplating ABS generally increases the rubber content in ABS and makes the rubber more evenly distributed in the material, thus making ABS easier to electroplating. Usually the rubber content of electroplated ABS is 15% to 25%. After electroplating grade ABS is treated with a mixed solution of sulfuric acid and chromic acid, the rubber content on the surface is eroded into irregular pores, so that metal particles can enter the pores during electroplating. And firmly adhere to the plastic surface to improve the adhesion between the electroplating layer and the plastic surface.

ABS electroplating products are used in the fields of electronic appliances and automobiles, such as door handles, decorative strips, heat dissipation grilles, and decorative strips for door panels of home appliances.

Transparent ABS

Transparent ABS is made by adding acrylic resin MMA to the three components of acrylonitrile (AN), butadiene (BD), and styrene (SM) to become acrylonitrile (AN) and acrylic resin (MMA) butadiene A copolymer made of four raw materials, ethylene (BD) and styrene (SM), has the characteristics of high transparency, high hardness, high rigidity, and high impact strength. The light transmittance of general transparent ABS can reach about 90.

Transparent ABS is widely used in electronic appliances, such as vacuum cleaners, smoking machines, toys, furniture, and medical products.

Glass fiber reinforced ABS

Glass fiber reinforced ABS is a mechanical performance of ABS by adding a certain proportion of glass fiber. Glass fiber reinforced ABS generally has a glass fiber content of 10% to 40%. The addition of 20% to 30% glass fiber is the most common. Generally, the higher the glass fiber content, the higher the tensile strength, bending strength, elastic modulus, and rigidity of the material. Well, the heat distortion temperature will also have a significant increase. However, if the glass fiber is added too much, the performance of the material will decrease.

Glass fiber reinforced ABS is used in outdoor fans of air conditioners, digital cameras, printers, power tools, and some electronic and electronic product enclosures.

Link to this article: Global production capacity and types of ABS resin

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

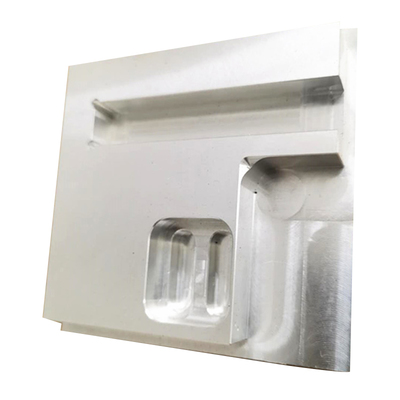

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material