Secret! CNC machining process for all-aluminum wheels hub

2019-03-22

The wheel hub, that is, the inner shape of the tire is used to support the barrel of the tire, and the center is assembled on the shaft. Common automotive wheels have steel wheels and aluminum alloy wheels. Steel wheels have high strength and are often used in large trucks;

if u need look ptj case studies,click wheel hub.

However, the steel wheels are heavy in weight and single in shape, which does not conform to the concept of low carbon and fashion today, and is gradually being replaced by aluminum alloy wheels.Advantages of aluminum alloy wheels

- (1) Compared with steel automobile wheels, the advantages of aluminum alloy wheels are obvious: the density is small, about 1/3 of steel, which means that the same volume of aluminum alloy wheels will be 2/3 lighter than steel wheels. Statistics show that the overall vehicle quality is reduced by 10%, and fuel efficiency can be increased by 6% to 8%. Therefore, the promotion of aluminum alloy wheels is of great significance for energy saving, low carbon life.

- (2) The thermal conductivity of aluminum is high, while the thermal conductivity of steel is low, so under the same conditions, the heat dissipation performance of aluminum alloy wheels is better than that of steel wheels.

- (3) Stylish and beautiful. The aluminum alloy can be aged and strengthened, and the aluminum alloy wheel slab without the aging treatment has low strength and is easy to be processed, and the aluminum alloy wheel after the corrosion-resistant treatment and the coloring is colored and exquisite.

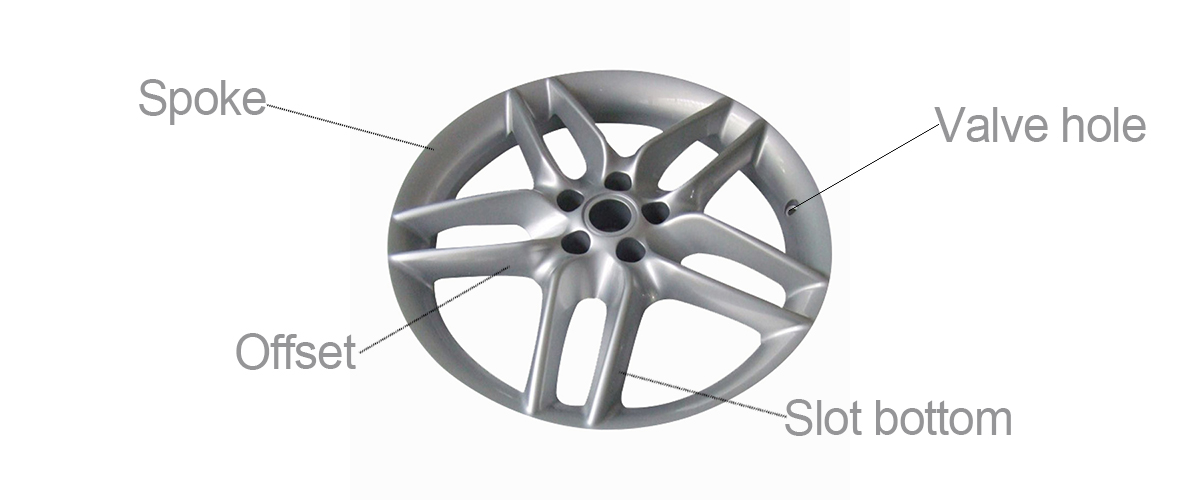

Structural Analysis of Automobile Aluminum Alloy Wheels

In order to meet the needs of the use of functions and the market, the aluminum alloy wheel hub has a variety of structural designs such as integral and multi-piece combination in structure; there are wide spokes, narrow spokes, multiple spokes, few spokes and other design designs. For safety reasons, the appearance and structural design of the aluminum alloy wheel must be based on the requirements for safety and functional use. For ordinary passenger cars, integral aluminum alloy wheels are sufficient to meet their performance requirements.The structure of the automobile hub is shown in Figure 1. It can be divided into two parts: the rim and the hub. The functional analysis of each part is shown in the figure below.

Performance requirements for automotive aluminum alloy wheels

There are many types and structures of aluminum alloy wheels, and their requirements vary depending on the type of vehicle and the model. However, strength and accuracy are the most basic requirements. According to market research, the wheel hub should have the following properties:- 1) The material, shape and size are correct and reasonable, and the function of the tire can be fully utilized and interchanged with the tire, which has international versatility;

- 2) When driving, the longitudinal and lateral oscillations are small, and the loss and the moment of inertia are small;

- 3) With sufficient weight, stiffness and dynamic stability under the premise of weight reduction;

- 4) good separability with shaft and tire;

- 5) has excellent durability;

- 6) The manufacturing process can meet the requirements of stable product quality, low cost, multiple varieties, and large-scale production.

Link to this article: Secret! CNC-Machining-Process for all-aluminum wheels hub

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Our Services

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

Case Studies

- Auto Metal Parts

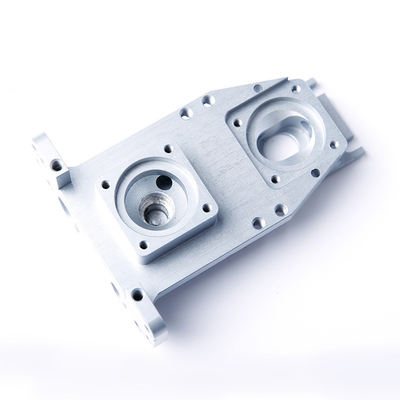

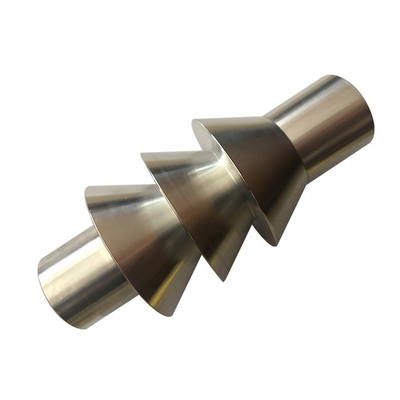

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

Material List

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material

Parts Gallery