Judge The Quality Of Laser Cutting From Several Sheet Metal Latitudes

Judge The Quality Of Laser Cutting From Several Sheet Metal Latitudes

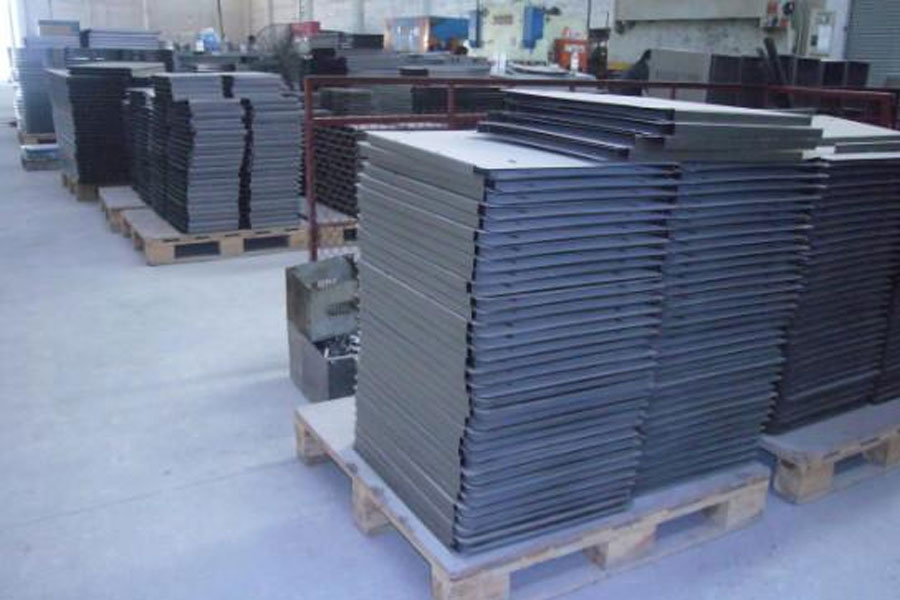

| In the process of sheet metal processing, there are many times when we don't know how to judge the quality of sheet metal processing. Today, the editor will explain to you how to judge the quality of sheet metal laser processing from several latitudes and evaluate its processing quality. |

How to judge the quality of sheet metal laser processing in sheet metal processing mainly includes the following points:

Smooth cut surface, few lines, no brittle fracture

When laser high-temperature cutting of the sheet, the traces of the molten material will not appear in the cut below the vertical laser beam, but will be sprayed out at the rear of the laser beam. As a result, curved lines are formed on the cutting edge, and the lines closely follow the moving laser beam. In order to correct this problem, reducing the feed rate at the end of the cutting process can greatly eliminate the formation of lines.

Narrow slit width

Generally speaking, the cutting width does not affect the cutting quality. The cutting width has an important effect only when a particularly precise contour is formed inside the component. This is because the cutting width determines the minimum inner warp of the contour. When the thickness of the sheet increases, the cutting width also changes. The increase. Therefore, in order to ensure the same high accuracy, no matter how large the width of the cut, the processing area of the laser cutting machine should be constant.

The cutting seam has good verticality, and the heat-affected area is small

When the thickness of the processed material exceeds 18mm, the verticality of the cutting edge is very important; when away from the focus, the laser beam becomes divergent, and the cutting becomes wider toward the top or bottom according to the position of the focus. The cutting edge deviates from the vertical line by a few hundredths of a millimeter. The more vertical the edge, the higher the cutting quality.

The thermal effect of cutting materials

Heat cutting processing application equipment will inevitably have a thermal impact on the material during use. Its manifestations mainly include three aspects: a. Heat affected area; b. Depression and corrosion; c. Material deformation

Heat-affected zone refers to the area around the incision being heated during laser cutting. At the same time, the structure of the material itself changes. For example, some materials will harden. The heat-affected zone refers to the regional change in which the internal structure changes due to high temperature.

The depression and corrosion have an adverse effect on the surface of the cutting edge and affect the appearance of the laser cutting machine. They appear in cutting errors that should generally be avoided; in the end, if the cutting causes the part to heat up sharply, it will deform.

This is especially important in fine processing, because the contours and connecting pieces here are usually only a few tenths of a millimeter wide. Controlling the laser power and using short laser pulses can reduce parts heating and avoid deformation.

The above is how to judge the quality of sheet metal laser processing in sheet metal processing. It is for reference only and I hope it will be useful to everyone.

Link to this article: Judge The Quality Of Laser Cutting From Several Sheet Metal Latitudes

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, sheet metal to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, laser cutting,drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material