The Advantages Of Turn-Mill Machining

What Are The Advantages Of Turn-Mill Machining?

|

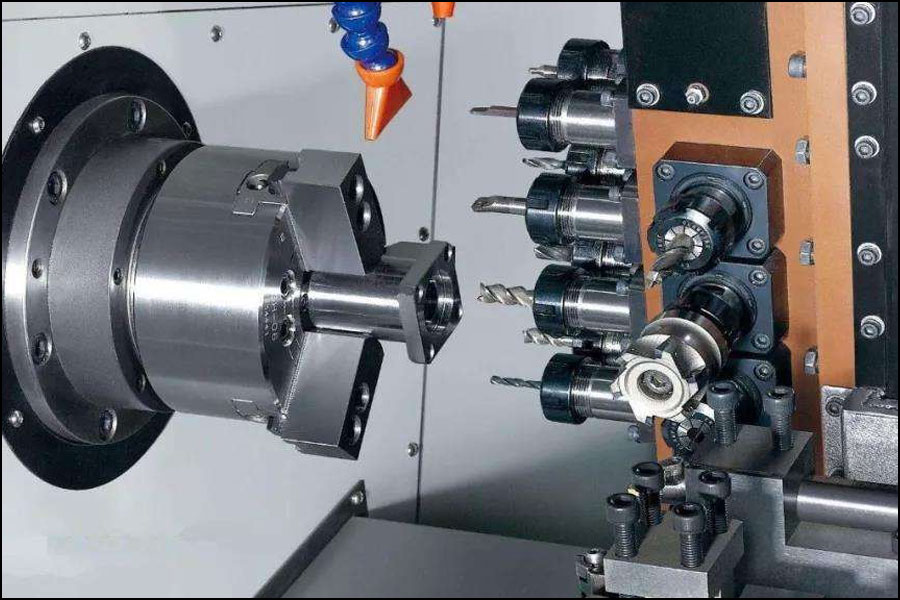

There are two main forms of Turn-Mill machining: contour machining when the workpiece is parallel to the tool axis; surface machining when the workpiece is perpendicular to the tool axis. Contour turn-mill machining is similar to machining the inner and outer contours of rotating workpieces through spiral interpolation milling. Surface machining turn-mill can only process the outer surface. Although the turn-mill looks very similar to turning, it is as simple as turning with a rotary milling cutter, but the two machining methods are essentially different. The cutting speed of Turn-mill machining depends on the speed of the milling cutter. The cutting speed, which is different from turning, is determined by the speed of the workpiece. In turning and milling, the workpiece speed is only related to the feed. |

- *First, the machining of discontinuous surfaces will lead to intermittent cutting, such as the machining of various grooves and root gaps. In classic turning, this operation generates impact loads that are not conducive to machining, resulting in poor surface quality and premature tool wear. In turn-mill machining, the tool used is a milling cutter, and milling itself performs intermittent cutting while the load changes periodically.

- *Second, when the processed material is a long chip material. In the turning process, chip formation is difficult to deal with. Finding the right chipbreaker for turning tools is not an easy task. The milling cutter used in turn-mill machining generates short chips, which significantly improves chip control.

- *Third, take crankshafts and spindles with eccentric journals as examples. During turning, the eccentric quality of workpieces such as crankshaft journals and eccentric cams will cause unbalanced forces and adversely affect machining, avoiding turning and The combination of milling has this negative effect due to the low speed of the workpiece.

The introduction of turn-mill compound machining in manufacturing not only solves the machining problems, but also greatly increases the output. Using relatively new machining methods, when you have the right modern machine tools and the right cutting tools, you will greatly increase your productivity.

The introduction of turn-mill compound machining in manufacturing not only solves the machining problems, but also greatly increases the output. Using relatively new machining methods, when you have the right modern machine tools and the right cutting tools, you will greatly increase your productivity.

Although CNC machine tools have been widely accepted and used, the development of metal cutting machine tools is still too traditional, and specific machine tools are developed according to their respective functions (such as turning, milling and drilling).

If machining centers equipped with rotating tools (such as milling cutters or drills) can be integrated for CNC turning, downtime can be shortened by reducing the number of times the workpiece is clamped and moved from this machine to another machine And increase the downtime machining efficiency; this demand for improved efficiency has led to the transformation of installing rotary power heads on traditional CNC lathes, thereby realizing turn-mill compound machining.

Today's modern multi-task machine tools have a B axis that allows tools to rotate and move, advanced control systems and advanced CAM software, so the workpiece can be clamped once to complete the main machining tasks.

Link to this article: The Advantages Of Turn-Mill Machining

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

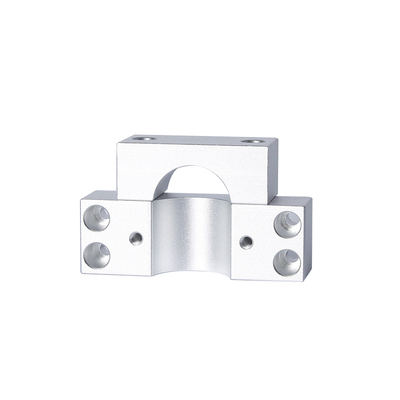

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material