Detail Definition of 1137 Tempered Steel

Definition of C1137 Tempered Steel

|

AISI1137 Grade: 1137 Standard: ASTM A29 / A 29M-05 Features and applications: Special Steel, American Special Steel C1137 Machining chemical composition: Carbon C: 0,, .32-0.39; Manganese Mn: 1.35-1.65 Phosphorus P: ≤0.040 Sulfur: 0.08-0.13 |

C1137 dimensional tolerance:

- 1137 sheet == required thickness 20mm == actual size 19.99 / 19.97mm == negative tolerance 0.01 ~ 0.03mm == pass

- 1137 sheet == required thickness 30mm == actual size 30.01 / 30.03mm == positive tolerance 0.01 ~ 0.03mm == pass

- 1137 bar == required diameter 60mm == actual size 59.99 / 59.97mm == negative tolerance 0.01 ~ 0.03mm == pass

- 1137 bar == required diameter 70mm == actual size 70.01 / 70.03mm == positive tolerance 0.01 ~ 0.03mm == pass

- 1137 pipe == required diameter 20mm == actual size 19.99 / 19.97mm == negative tolerance 0.01 ~ 0.03mm == pass

- 1137 pipe == required diameter 30mm == actual size 30.01 / 30.03mm == positive tolerance 0.01 ~ 0.03mm == pass

【1137 Combined Steel Heat Treatment Method and Features】

- ① Solid solution strengthening is an important form of metal strengthening. The phenomenon of increasing the strength and hardness of metal by forming a solid solution. When the solute content is appropriate, the strength and hardness of the material can be significantly improved, while the plasticity and toughness are not significantly reduced, which is its biggest feature.

- ② Aging is divided into artificial aging and natural aging. Natural aging strengthening is to strengthen the alloy during standing at room temperature; artificial aging strengthening is to strengthen the alloy during low temperature heating. Both are based on the premise of solid solution strengthening, both to improve the strength of the alloy.

- ③ Precipitation strengthening is premised on aging strengthening, the purpose is to strengthen the alloy. The addition of cobalt, tungsten, molybdenum and other elements makes the alloy obtain a very high yield strength.

- ④ Grain boundary strengthening occurs because the grain boundary of the alloy is a weak link at high temperatures. Adding trace amounts of boron, zirconium and rare earth elements can improve the strength of the grain boundary.

- ⑤ Annealing: The annealing state is the basic state of the furnace. The essence is to transform the nickel alloy from austenite to pearlite.

The role is to reduce the hardness of the nickel alloy surface and improve the plasticity to facilitate cold deformation processing such as cutting; make the composition of steel uniform, improve performance, and prepare for further heat treatment; eliminate stress to prevent deformation or cracking.

Molybdenum

It can significantly improve the hardenability and heat strength of steel, prevent tempering brittleness, and improve remanence and coercive force.

Nickel-based shape memory alloy. Nickel alloy containing 50 (at)% titanium. The recovery temperature is 70 ° C, and the shape memory effect is good. A small change in the nickel-titanium composition ratio can change the recovery temperature in the range of 30 to 100 ° C.

Link to this article: Detail Definition of 1137 Tempered Steel

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

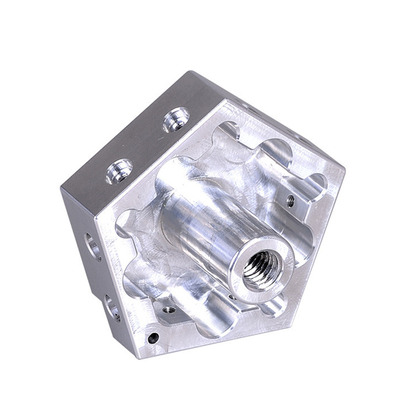

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material