The Status And Prospect Of Laser Precision Machining Technology

The Status And Prospect Of Laser Precision Machining Technology

|

Laser material machining involves a wide range. Sintering, punching, marking, cutting, welding, surface modification and chemical vapor deposition of materials have all taken laser as an indispensable energy source. |

The laser beam can be focused to a very small size, making it particularly suitable for precision machining. We divide the current laser machining technology into three levels according to the size of the processed material and the accuracy requirements of the machining:

- ① Laser machining technology for large-scale materials, with thick plates (several millimeters to tens of millimeters) as the main object, and its machining accuracy is generally at the millimeter or sub-millimeter level;

- ② Precision laser machining technology, with thin plates (0.1 to 1.0mm) as the main machining object, and its machining accuracy is generally in the order of ten microns;

- ③ Laser microfabrication technology, for various films with a thickness of less than 100μm as the main machining object, its machining accuracy is generally below 10 microns or even sub-micron level.

It must be noted that in the machinery industry, precision usually means small surface roughness and a small range of tolerances (including position, shape, size, etc.). However, the term "precision" in this article refers to the small gap in the area being processed, which means that the limit size that can be processed is small. In the above three types of laser machining, the laser machining technology of large parts has become increasingly mature and the degree of industrialization has been very high.Many literatures have been reviewed; laser micro machining technologies such as laser trimming, laser precision etching, laser Direct writing technology has also been widely used in industry, and there are many related reports. This article will focus on laser precision machining technology. For the sake of convenience, the machining targets for precision machining mentioned below are limited to thin plates (0.1-1.0mm).

1 .Comparison between laser precision machining and traditional machining methods

With the advancement of technology, the types of precision machining technology are becoming more and more abundant.

Laser precision machining has the following significant features:

- ①The scope of laser precision machining is wide, including almost all metallic and non-metallic materials. While electrolytic machining can only process conductive materials, photochemical machining is only suitable for easily corrosive materials, and plasma machining is difficult to process certain high melting point materials.

- ② There are few influencing factors on the quality of laser precision machining, and the machining accuracy is high, and it is generally better than other traditional machining methods in general.

- ③ From the perspective of the machining cycle, the tool electrode of EDM requires high precision, large loss, and a long machining cycle; the design of the cathode mold for the machining cavity and profile of electrolytic machining is large, and the manufacturing cycle is also long; The procedures are complicated; the laser precision machining is simple, the slit width is easy to adjust and control, the machining speed is fast, and the machining cycle is shorter than other methods.

- ④Laser precision machining belongs to non-contact machining, without mechanical force. Compared with EDM and plasma arc machining, its heat affected zone and deformation are very small, so it can process very small parts.

In summary, laser precision machining technology has many advantages over traditional machining methods, and its application prospect is very broad.

2. Introduction to commonly used laser precision machining equipment

Lasers commonly used for precision machining include: CO2 lasers, YAG lasers, copper vapor lasers, excimer lasers, and CO lasers, etc. For their laser characteristics, see the literature for details.

Among them, high-power CO2 lasers and high-power YAG lasers are widely used in large-scale laser machining technology; copper vapor lasers and excimer lasers are more widely used in laser micro-machining technology; medium and low-power YAG lasers are generally used for precision machining .

3. Application of laser precision machining and development of China and international

3.1 International status

3.1.1 Laser precision drilling

With the advancement of technology, the traditional punching method has been unable to meet the needs in many occasions. For example, small holes with a diameter of several tens of micrometers are processed on hard tungsten carbide alloys; deep holes with a diameter of several hundred micrometers are processed on hard and brittle red and sapphire, etc., which cannot be achieved by conventional machining methods. The instantaneous power density of the laser beam is as high as 108 W / cm2, which can heat the material to the melting point or boiling point in a short time to achieve perforation on the above materials. Compared with electron beam, electrolysis, electric spark, and mechanical drilling, laser drilling has good quality, high repeat accuracy, strong versatility, high efficiency, low cost, and significant comprehensive technical and economic benefits. International precision laser drilling has reached a very high level. A Swiss company uses solid-state lasers to punch holes in aircraft turbine blades, which can process microholes with a diameter from 20 μm to 80 μm, and the ratio of diameter to depth can reach 1:80 (see Figure 1 (a)). The laser beam can also process various special-shaped holes such as blind holes (see Figure 1 (b)) and square holes on brittle materials such as ceramics, which cannot be achieved by ordinary machining.

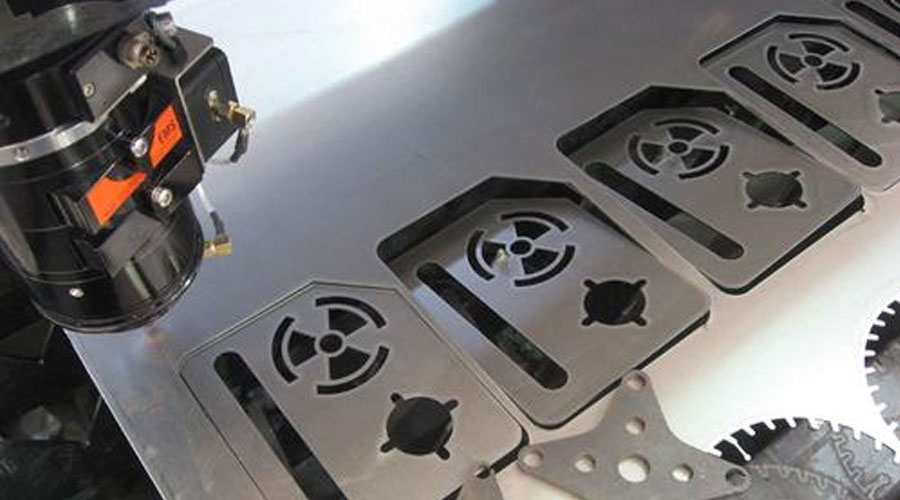

3.1.2 Laser precision cutting

Compared with the traditional cutting method, precision laser cutting has many advantages. For example, it can make narrow incisions, almost no cutting residue, small heat affected zone, low cutting noise, and can save 15% to 30% of material. Because the laser hardly produces mechanical impulse and pressure on the material being cut, it is suitable for cutting hard and brittle materials such as glass, ceramics and semiconductors.In addition, the laser spot is small and the slit is narrow, so it is particularly suitable for small parts. Kind of precision cutting. A Swiss company uses solid-state lasers for precision cutting, and its dimensional accuracy has reached a very high level.

A typical application of laser precision cutting is cutting SMT stencils in printed circuits boards (see Figure 2). The traditional SMT template machining method is a chemical etching method. Its fatal disadvantage is that the limit size of the machining must not be less than the thickness of the plate, and the chemical etching method has a complicated process, a long machining cycle, and the corrosive medium pollutes the environment.

Using laser machining can not only overcome these shortcomings, but also reprocess the finished template.In particular, the machining accuracy and gap density are significantly better than the former (see Figure 3). Is slightly lower than the former. However, due to the high technological content of the entire set of equipment used for laser machining and the high price, only a few companies in a few countries such as the United States, Japan, and Germany can produce the entire machine.

3.1.3 Laser precision welding

Laser welding has a very narrow heat-affected zone and a small weld seam. In particular, it can weld high melting point materials and dissimilar metals without the need for additional materials. International use of solid YAG lasers for seam welding and spot welding has reached a high level. In addition, the lead wires of the printed circuit are welded by laser, which does not require the use of a flux, and can reduce thermal shock without affecting the circuit die, thereby ensuring the quality of the integrated circuit die (see Figure 4).

3.2 Current situation in China

After more than 20 years of efforts, in terms of laser precision machining technology and complete equipment, although China has been used in ceramic laser scribing and laser spot welding of micro-small metal parts, seam welding and air-tight welding, and marking, etc.

However, in the laser precision machining technology, the microelectronic circuit template precision cutting and etching process with high technical content and broad application market, through-holes, blind holes and special-shaped holes, slots of various specifications and sizes on ceramic sheets and printed circuit boards Laser precision machining and other aspects are still in the research and development stage, and no corresponding industrial prototype has appeared.

The majority of users in China generally use imported templates or commission machining in Hong Kong and other places.The high price and long cycle have seriously affected the product development cycle. In recent years, a few large international companies have seen China's huge potential market in the laser precision machining industry. , Has begun to set up branches in China. However, high machining costs increase product costs and still make many enterprises discourage them.

4. Development Trend and Prospect of Laser Precision Machining Technology

High-quality, efficient, stable, reliable, and cheap lasers are the prerequisites for the promotion and application of precision machining. One of the development trends of laser precision machining is the miniaturization of machining systems. In recent years, diode-pumped lasers have developed rapidly. It has a series of advantages such as high conversion efficiency, good work stability, good beam quality, and small size. It is likely to become the main laser for the next generation of laser precision machining.

Integration of machining systems is another important trend in the development of laser precision machining. Systematize and improve the laser precision machining technology for various materials; develop user-friendly, dedicated control software suitable for laser precision machining, and supplement it with the corresponding process database; combine control, process and laser to achieve optical, The integration of machine, electricity and material machining is an inevitable trend in the development of laser precision machining.

Although China has a large gap with the international in terms of laser machining technology and equipment, if we continue to improve the laser beam quality and machining accuracy based on the original, combined with the research of material machining technology, we will occupy the laser precision machining market as much as possible. And gradually penetrate into the field of laser micro-machining, can promote the rapid development of laser cutting technology, and eventually make laser precision machining into a large-scale industry.

Link to this article: The Status And Prospect Of Laser Precision Machining Technology

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material