The Characteristics Of CNC Turning Technology

What are the characteristics of CNC turning technology?

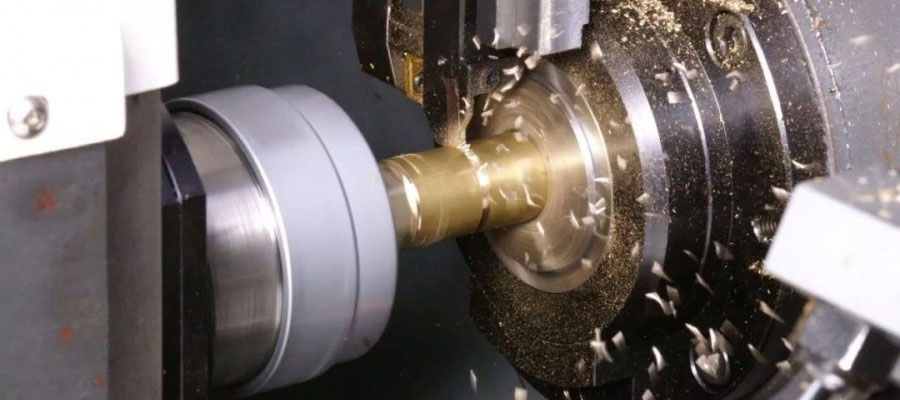

| Turning is a method of cutting a workpiece on a lathe using a workpiece relative to the tool rotation. Turning is the most basic and common cutting method. Most workpieces with a rotating surface can be machined by turning, such as inner and outer cylindrical surfaces, inner and outer conical surfaces, end faces, grooves, threads and rotary forming surfaces. Common lathes can be divided into horizontal lathes, floor lathes, vertical lathes, turret lathes, and profiling lathes, most of which are horizontal lathes. |

Due to the development of modern science and technology, various high-strength and high-hardness engineering materials are increasingly used. Traditional turning technology is difficult or impossible to realize the processing of certain high-strength and high-hardness materials. Hard turning technology makes this possible and delivers significant benefits in production.

Introduction to the characteristics of turning

(1) High turning efficiency

Turning has higher efficiency than grinding. Turning often uses large depth of cut and high workpiece speed. The metal removal rate is usually several times that of grinding. One-time clamping can complete a variety of surface machining during turning, while grinding requires multiple installations, so the auxiliary time is short and the positional accuracy between the machined surfaces is high.

(2) Low equipment input cost

When the productivity is the same, the lathe investment is obviously better than the grinding machine, and the auxiliary system cost is also low. For small batch production, turning does not require special equipment, while high-volume machining of high-precision parts requires CNC machines with good rigidity, positioning accuracy and high repeatability.(3) Suitable for small batches

Flexible production requires that the lathe itself is a flexible processing method with a wide processing range. The lathe is easy to operate and the turning and clamping is fast. Compared with grinding, hard turning can better meet the requirements of flexible production.(4) Hard turning can achieve good overall machining accuracy of parts

Most of the heat produced in hard turning is taken away by the cutting oil. It does not produce surface burns and cracks like grinding. It has excellent surface quality and precise roundness. It can ensure a high degree between the machined surfaces. Positional accuracy.

Turning tool materials and their selection

(1) Coated carbide tool

Coated cemented carbide tools are coated with one or more layers of good wear resistance on hard tough carbide tools. The coating usually plays the following two roles: on the one hand, it has a specific tool The much lower heat transfer coefficient of the substrate and the workpiece material weakens the thermal action of the tool base; on the other hand, it can effectively improve the friction and adhesion of the cutting process and reduce the generation of cutting heat. Compared with cemented carbide tools, coated carbide tools offer significant improvements in strength, hardness and wear resistance.

(2) Ceramic material cutter

Ceramic knives have the characteristics of high hardness, high strength, good wear resistance, good chemical stability, good anti-blocking performance, low friction coefficient and low price. When used normally, it is extremely durable and can be several times faster than cemented carbide. It is especially suitable for high hardness material processing, finishing and high speed machining.

(3) Cubic boron nitride cutter

The hardness and wear resistance of cubic boron nitride is second only to diamond, and it has excellent high temperature hardness. Compared with ceramic tools, its heat resistance and chemical stability are slightly poor, but impact strength and crush resistance are better. It is widely used in the machining of hardened steel, pearlitic gray cast iron, chilled cast iron and high temperature alloys, and its cutting speed can be increased by an order of magnitude compared with cemented carbide tools.

Selection of cutting oil

- (1) Tool steel cutters have poor heat resistance and lose hardness at high temperatures. Therefore, it is required to use cutting oil with good cooling performance and low viscosity.

- (2) When high-speed steel cutting tools are used for high-speed rough cutting, the cutting amount is large and a large amount of cutting heat is generated, and a cooling oil with good cooling properties should be used. If high-speed steel tools are used for medium and low-speed finishing, low-viscosity cutting oil is generally used to reduce the frictional bond between the tool and the workpiece, suppress the formation of the cutting tumor, and improve the machining accuracy.

- (3) Cemented carbide tools have higher melting point and hardness, better chemical and thermal stability, and better cutting and wear resistance than high-speed steel tools. Active sulfur cutting oil can be used in general processing. If it is heavy cutting, the cutting temperature is very high, and it is easy to wear the tool very quickly. At this time, the inactive vulcanized cutting oil should be selected and the flow rate of the cutting oil should be increased to ensure sufficient cooling and lubrication.

- (4) Ceramic tools, diamond tools and cubic boron nitride tools have high hardness and wear resistance. Low-viscosity inactive vulcanized cutting oil is generally used for cutting to ensure the surface finish of the workpiece.

Link to this article: The Characteristics Of CNC Turning Technology

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material