-

Five Reliable Solutions To The Plastic Crisis

According to foreign media reports, the plastic crisis is one of the challenges facing our global environment. At present, about 1270 tons of plastic flows into the ocean every year, which causes great harm to marine life, and can cause sea turtles to be entangled and suffocated by plastic objects, or even large in size. The whales are not immune, they swallowed plastic garbage and died of poisoning. Obviously, the main solution is to reduce the use of plastic products by humans. At present, people are beginning to develop new technologies, through diffusion thinking, and even through other species to find answers to the earth’s crisis.

2021-10-30

-

How To Distinguish Copper Material And Its Use

For copper, everyone may have become accustomed to it. In our daily life, each of us can be said to be inseparable from copper products, but even so, there are still many people who can’t distinguish the same material correctly. Let the editor lead you today. Identify the various types of copper materials and talk about their uses by the way.

2021-10-16

-

New Method For Testing Nuclear Fuel Strength

Scientists from the Moscow Institute of Engineering Physics of the Russian National Nuclear Research University have developed a new method for testing the strength limit of the fuel in nuclear fuel pellets-the "Russian Brazil Test".

2021-10-16

-

Is Cast Iron a Metal, Ceramic, or Polymer?

The classification of cast iron, whether as a metal, ceramic, or polymer, requires a detailed examination of its composition, properties, and behavior.

2024-08-19

-

How to determine the size of machines and tools used for industrial parts?

Today's industrial blow molding machines are efficient and predictable, and can usually rely on it to produce precision parts from the beginning. However, it is still wise to know some basic guidelines to help you get started with appropriately sized equipment and tools, especially if you are making a specific part for the first time.

2021-10-28

-

Stainless Steel 201 vs. 304

This article aims to provide an in-depth comparison of Stainless Steel 201 and 304, exploring their chemical compositions, mechanical properties, applications, advantages, and disadvantages.

2024-08-19

-

Solve four common problems in PET stretch blow molding

The knowledge of blow molding technology provides tips on how to solve the uneven wall thickness in stretch blow molding. Although this is a vital issue, it is not the only issue that processors must deal with every day. Here are four other frequently asked questions, applicable to single-stage and two-stage processes.

2021-10-28

-

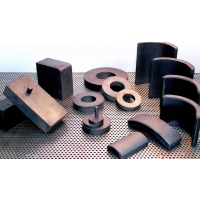

What Is Soft Magnetic Material

Soft magnetic materials are a class of materials that exhibit high magnetic permeability and low coercivity (or low magnetic field strength required to magnetize them).

2024-07-29

-

The larger the build volume of the 3D printer, the greater the chance of building a whole object

When founder Scott Crump invented Fused Deposition Modeling (FDM), he was looking for "a simple way to make a toy frog for his daughter." In 1988, he applied for a patent for a hot glue gun under CNC control, which has since become one of the pillars of the 3D printing industry.

2021-10-28

-

How Hot Dip Galvanizing Protects Steel?

This article provides an extensive overview of the hot dip galvanizing process, its benefits, applications, and the science behind how it protects steel from corrosion.

2024-06-24

-

How to quantify the appearance of plastics?

Many factors affect the appearance of plastic. Here, the editor of Xianji.com will discuss the three most common ones: gloss, reflection haze and transmission haze.

2021-10-28

-

CNC Machining ABS Plastic 101:A Beginner’s guide

This article delves into the considerations, common issues, and troubleshooting techniques associated with CNC machining of ABS plastic.

2024-06-24

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

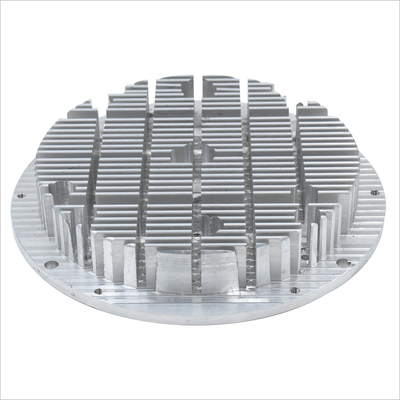

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material