-

What exactly is 3D printing technology?

Since 2009, the main patents for portable 3D printers have expired, and 3D printing has developed into an industry of its own. Therefore, 3D printers are one of the decisive products of our time.

2021-10-27

-

What are the common problems in the coextrusion blown film process?

The blown film industry has developed from a single-layer film structure to a multi-layer film structure for various food and non-food packaging applications. According to the requirements of the product, a variety of materials can be integrated into the film structure to obtain the required performance.

2021-10-27

-

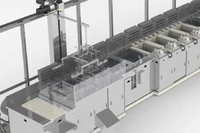

What are the tips for cleaning the twin screw extruder?

Twin-screw extruders (TSEs) have long been the machine of choice for compounding machines due to their superior performance and customizability. They can handle almost all resins and combine different additives and fillers to achieve different particle sizes and shapes with different properties.

2021-10-27

-

Welded plate heat exchangers help prevent unplanned downtime and reduce costs

Unplanned downtime is one of the biggest challenges and expenditures facing processors. The main causes of unplanned downtime include unexpected equipment maintenance and breakdowns. In the chemical and other process industries, the average annual cost of unplanned shutdowns is estimated at 20 billion U.S. dollars, accounting for almost 5% of production. In the petrochemical industry, unplanned shutdowns cause 2% to 5% production losses.

2021-10-27

-

4D printing subverts the lifestyle of the future!

Imagine that from particleboard bookshelves to apartment buildings, the machines and structures we use every day can be assembled. No more IKEA hex wrenches, no cranes, only 3D printed materials "know" how to fold, curl and harden, just like plants growing in time-lapse video.

2021-10-27

-

What is the relationship between part cleaning and quality and yield?

Most finishers claim that they believe that part cleaning helps optimize quality, productivity, and profitability. However, although the store's views and opinions on the cleaning process are fairly uniform, there are still differences in quality qualification rates.

2021-10-27

-

What preparations should a welder take before touching an arc?

The work done before the first arc is drawn will have a huge impact on the scope of the project and the integrity of the metal. Whether it is from the production of project plans and organization of materials, or from the inspection and cleaning of materials, these preparations should be completed before the start of welding.

2021-10-27

-

Five key factors for choosing precision linear modules!

·Semiconductor manufacturing, laser cutting machine tools, electronic assembly, and laboratory automation systems all require precise linear modules. These modules need to run smoothly with strict endpoint accuracy and minimal vibration.

2021-10-26

-

5 tips for increasing welding output: helping companies break the bottleneck period

Increasing welding output is not a one-step process. To achieve results, you need to invest time, labor, and money. Carrying out such a project also requires an open mind, assessing whether a particular modification makes sense, and if it is feasible, prepare to make changes.

2021-10-26

-

What role can flux play in the submerged arc welding (SAW) process?

What role can flux play in the submerged arc welding (SAW) process? How is it made and classified? Today, the editor of Xianji.com will take everyone to learn together.

2021-10-26

-

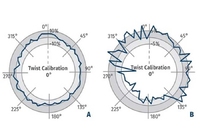

Bending machines enable fabs to produce challenging products, making spiral processing more predictable

You might think that only craftsmen with years of experience and great attention to detail can make spirals, but that's not the case.

2021-10-26

-

Process and technical points of passivation of stainless steel parts

Passivation is affected by the cleanliness of the parts and also by the choice of acid. Is the effect of nitric acid or citric acid the most? Xianji.com has translated and compiled some foreign materials.

2021-10-26

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material