The Selection And Assembly Of Bearings For Machining Special Machines

Bearings are important basic parts of various mechanical equipment. Its accuracy, performance, life and reliability play a decisive role in the accuracy, performance, life and reliability of the host. Among mechanical products, bearings are high-precision products. The accuracy of key processing procedures is guaranteed by the accuracy of the bearings in the spindle and guide sleeve. Correct selection and installation can ensure the accuracy, performance, life and reliability of the bearings.

There are many applications of bearings in machining production lines. The main shaft gearbox, tooling guide sleeve, chip removal system, etc. are inseparable from the use of bearings. The correct selection and assembly of bearings according to the force direction of the transmission components can ensure the internal transmission components of the spindle box and The service life of the tooling guide sleeve and the machining accuracy of the spindle.

There are many types of rolling bearings, and bearings can be selected according to the direction and size of the load.

1. Deep groove ball bearings

Deep groove ball bearings are simple in structure and easy to use. They are the largest type of bearing with the largest production batch and the widest application range. Mainly bear radial load, but also can bear certain axial load. When the radial clearance of the bearing is increased, it has the function of an angular contact ball bearing, which can bear a larger axial load, but it cannot bear the axial load alone. Compared with other types of bearings of the same size, this type of bearing has a lower friction coefficient and a higher limit speed.

Features:

- 1. High precision and high speed.

- 2. Low noise and low precision.

- 3. Simple manufacturing and low cost.

- 4. Mainly bear radial load and can bear certain axial load.

It is suitable for partial transmission such as motor drive and spindle box drive of the machining production line. It is easy to install and does not need to adjust the pre-tightening force.

2. Self-aligning ball bearings

The self-aligning ball bearing has two rows of steel balls, the inner ring has two raceways, and the outer ring has an inner spherical shape, which has the performance of self-aligning and can automatically compensate for the coaxiality error caused by the deflection of the shaft. It is suitable for parts where the support seat hole cannot guarantee strict coaxiality.

Features:

- 1. The raceway of the outer ring is spherical and self-aligning.

- 2. It can compensate the errors caused by the misalignment and shaft deflection caused by self-aligning ball bearings.Suitable for sprocket chip removal and motorized sprocket conveying part.

3. Spherical roller bearings

Spherical roller bearings have two rows of rollers, which are mainly used to bear radial loads and can also bear axial loads in any direction. It has high radial load capacity, especially suitable for working under heavy load or vibration load, but it cannot bear pure axial load. It has good centering performance and can compensate the error of coaxiality.

Features:

- 1. Low speed, impact resistance and vibration resistance.

- 2. With automatic centering function, that is, when the axis of the inner ring is inclined relatively to the axis of the outer ring (usually within 3 degrees), it can still operate normally.

- 3. Mainly bear large radial load and small axial load. Suitable for sprocket chip removal and motorized sprocket conveying part.

4.Tapered roller bearings

Tapered roller bearings are mainly used to bear combined radial and axial loads based on radial loads; tapered roller bearings with large cone angles can be used to bear combined radial and axial loads based on axial loads. Single row tapered roller bearings must be used in pairs, because tapered roller bearings generate axial force when they are subjected to radial loads. In order to offset this additional additional load, they must be borne by another set of opposite bearings to offset each other’s axial distribution. The influence of force. The tapered roller bearing is a separable bearing, and its inner ring and outer ring can be installed separately. The radial clearance and axial clearance of the bearing can be adjusted during installation and use, and it can also be installed with pre-interference.

Features:

- 1. Large cone angle tapered roller bearings can bear radial load and axial load at the same time.

- 2. The outer ring can be separated, and the installation time can adjust the gap of the bearing.

Generally used in pairs. It is applied to the internal transmission shaft of the equipment headstock, but it needs proper pre-tightening force, otherwise the potential can not be realized.

5. Cylindrical roller bearings

The roller of the cylindrical roller is usually guided by two ribs of a ring. The cage, the roller and the guide ring form an assembly, which can be separated from the other bearing ring and is a separable bearing. This kind of bearing is more convenient to install and disassemble, especially when the inner and outer ring and the shaft and the shell are required to be interference fit. This type of bearing is generally only used to bear radial load. Only single row bearings with ribs on the inner and outer rings can bear smaller directional axial loads. Compared with deep groove ball bearings with the same external dimensions, this bearing has a larger radial load carrying capacity.

Features:

- 1. The speed is lower than that of the ball bearing of the same size.

- 2. High precision, low noise and vibration.

- 3. Mainly bear radial load, the inner and outer rings with ribs can bear small axial load.

It is suitable for milling machine spindle with high precision and stable transmission. It requires corresponding pre-tightening force and spacer adjustment during installation.

6.Needle bearing

Needle roller bearings are equipped with slender and long rollers, so the radial structure is compact. When the inner diameter and load capacity are the same as other bearing types, the outer diameter is small. It is especially suitable for supporting structures with restricted radial installation dimensions. Depending on the application, a bearing without an inner ring or a needle roller and cage assembly can be selected. At this time, the journal surface and the shell hole surface that match the bearing are directly used as the inner and outer raceway surfaces of the bearing to ensure the bearing capacity The running performance is the same as that of the ring bearing, the hardness, machining accuracy and surface quality of the rolling surface of the shaft or housing hole should be similar to the raceway of the bearing ring.

Features:

- 1. Higher speed.

- 2. Higher rigidity.

- 3. It can bear higher radial load (larger than other bearings with the same radial size) and cannot bear axial load. It is suitable for the installation of the main shaft part of the headstock, with good rigidity and large radial load.

7.Angular contact ball bearings

Angular contact ball bearing steel ball and outer ring raceway contact point between the bearing line of action and the bearing radial plane is an angle, this angle is the nominal contact degree. Angular contact ball bearings have a high limit speed, and can bear radial and bearing loads at the same time, and can also bear pure axial loads. Its axial load-bearing capacity is determined by the contact angle. Single row angular contact bearings can only bear axial load in one direction. When bearing radial force, additional axial force will be caused. And it can only limit the axial displacement of the shaft or housing in one direction.

Features:

- 1. High speed and high precision.

- 2. Low noise and low precision.

- 3. It can bear radial load and axial load at the same time, and can be used in pairs.

It is suitable for guide bushings, boring heads, etc., which require high installation requirements. It needs to be equipped with spacers and adjust the bearing clearance through pre-tightening force to wait for high reliability accuracy.

8. Combined bearings

Combined bearing is a bearing with two or more rolling elements used to bear radial and axial loads or act as an axial limit.

Features:

- 1. The combined bearing can bear two-way axial load and radial load, with high accuracy and rigidity.

- 2. When assembling, stop using the method of hitting the non-assembly ring to force the rolling element to prevent the accuracy from falling.

It is generally suitable for transmission of equipment with large bidirectional load, such as BU118 gear shaft, DGU083 main shaft and other parts.

The correct installation of the bearing affects its accuracy, life and performance. Therefore, the installation of bearings must be fully studied. Need to be installed in accordance with operating standards. The standard operation items are usually as follows:

- (1) Clean the bearing and its related parts

- (2) Check the size and finishing of related parts

- (3) Install

- (4) Check after the bearing is installed

- (5) Supply grease

How to install the bearing

Depending on the bearing structure, fit, and conditions, in general, because most of the shaft rotates, the inner ring needs an interference fit. Cylindrical bore bearings are usually pressed in with a press or hot-fitting method. In the case of a tapered hole, install it directly on the tapered shaft or install it with a sleeve.

When installed to the shell, there is generally a lot of clearance fit, and the outer ring has an interference. It is usually pressed in with a press, or there is also a shrink fit method for installation after cooling. When dry ice is used as the coolant, the moisture in the air will condense on the surface of the bearing when the shrink fit is installed.

Therefore, appropriate anti-rust measures are required. In order for the bearing to give full play to and maintain its due performance for a long time, it is necessary to do a good job of regular maintenance (regular inspection). Through appropriate regular inspections, it is very important to improve productivity and economy to detect faults early and prevent accidents before they occur.

Matters needing attention during installation:

- 1. Using brute force during installation, directly hitting the bearing with a hammer will cause the greatest damage to the bearing; it is the main cause of deformation.

- 2. The installation is not in place, the installation is deviation or the bearing is not installed, resulting in too small bearing clearance. The inner and outer rings are not at the same center of rotation, resulting in different concentricity.

Concluding remarks

Bearings should be adjusted according to the force direction of the transmission components to improve the service life and accuracy of the transmission components and bearings. When installing the bearings, be careful and bold, only careful installation and deployment. In order to achieve the desired effect.

Link to this article:The Selection And Assembly Of Bearings For Machining Special Machines

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

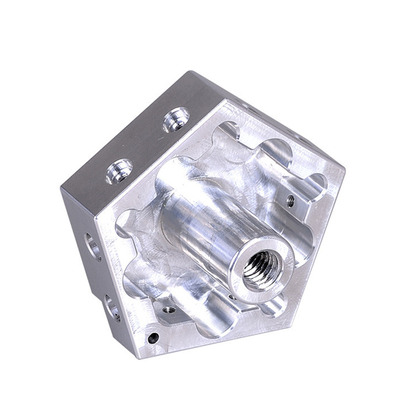

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material