Maintenance of cooling and hydraulic system of cold chamber die casting machine

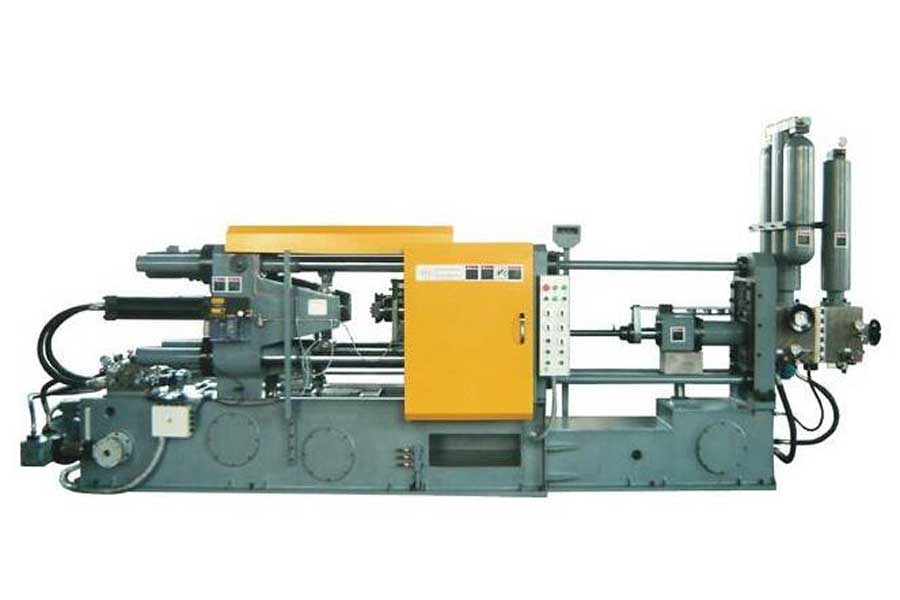

The cold chamber die casting machine is a kind of die casting equipment. The principle is to pour the molten metal liquid into the injection chamber (into the barrel) through the soup spoon, and then use the injection piston (hammer) to push the metal liquid into the mold at high speed. In the case of maintaining a certain pressure, it is a kind of casting equipment that is cooled and solidified to obtain a finished product.

Maintenance of cooling system of cold chamber die casting machine

1. The water pipes connected to the cooling system should be overhauled once a year to check whether the pipes are corroded or leaking, otherwise they should be repaired and replaced in time.

2. The machine cooling water should be purified fresh water, the river water must be filtered through a water tower, and the filter device needs to be cleaned every six months.

3. After the cooler usually works for half a year, the inner surface of the pipe wall is dirty and the heat exchange performance decreases. The outer cover at both ends of the cooler should be removed to clean up the deposits.

Maintenance of the hydraulic system of the cold chamber die casting machine

For the maintenance of the oil circuit part, first of all, we must ensure the use of qualified hydraulic oil. The die-casting machine should prevent the use of deteriorating, thickened and sedimentary hydraulic oil. When changing the hydraulic oil, do not mix the new and old hydraulic oil. After each oil change Be sure to install the fuel tank cap. The maintenance of the oil circuit part mainly includes the following aspects.

1. Check the filter vacuum gauge monthly, the normal indication value should be in the green range when starting up, otherwise it needs to be cleaned. For the filter without the indication of the vacuum gauge, clean the filter once every three months and check whether the filter is damaged, otherwise it needs to be replaced.

2. Check and repair the oil pump every other year. Check the wear of the valve plate, suction and pressure working chamber and other related parts. If the wear is serious, the internal leakage will be large and the pressure loss will be large. It should be repaired or replaced in time.

3. When the die-casting machine is in normal use, the hydraulic oil needs to be replaced every 2000 operating hours. It is recommended to use Hercules ZONA ISO VG68 high clean hydraulic oil or Caltex 68 anti-wear hydraulic oil.

4. The oil tank must be cleaned thoroughly when replacing the hydraulic oil. After opening the oil tank cover, pay attention to cover it to prevent the oil, dust, iron filings and other sundries from being mixed into the oil.

The oil change procedure is as follows:

① System flushing: Generally, the die-casting machine that changes the oil according to the prescribed procedures, there is not much water stains and glue, and there is no black oil similar to bitumen at the bottom of the oil tank. As long as the new oil is flushed with 1/3-1/2 of the tank capacity, the purpose is to wash away the old oil, leaving no or little old oil.

If the oil is not changed completely, only part of the new oil is added, and the system does not need to be flushed, but pay attention to whether the newly added oil is an anti-wear hydraulic oil of the same brand and the same viscosity from the same supplier. Otherwise, the total mixing experiment is to be done, and the method is as follows: respectively take half of the new oil and the old oil into the container; put 1/3 of the new oil and 2/3 of the old oil into another container, and put it in 70- Put it in a constant temperature of 800C for 24 hours, carefully observe whether there is turbidity or precipitation, if not, it can be used.

②Filling new oil: The new oil filling amount of the die-casting machine is related to the model, and the specific oil filling amount is in accordance with the requirements of the machine manual.

③ Trial run: After adding new oil, run for 10-15 minutes without load, and then load into normal operation after the temperature and pressure are normal.

5. Check once every other year whether the spools of the reversing valve, overflow valve, pressure reducing valve, relief valve, one-way valve, etc. are worn and whether there is internal leakage. Check the relief valve, whether the orifice of the pressure reducing valve is blocked, and whether the pressure control is sensitive and accurate.

6. After the drain valve filter (2142-00025) is blocked, the electric indicator will send out an alarm signal. At this time, it indicates that the high-pressure filter is blocked by dirt, and the filter element needs to be replaced. The accessory number is 2142-00068.

7. Check every six months whether there is any looseness in the connecting oil pipe joints and the installation screws of the oil valve. If there is any looseness, it should be tightened in time to prevent leakage or air from entering the hydraulic system.

8. Check every other year whether the mold opening and clamping cylinders, the injection cylinders, and the thimble cylinders are drawn, and the seals are worn or damaged. Otherwise, they should be repaired or replaced to avoid greater pressure loss.

9. The overflow valve, electro-proportional valve, and pressure reducing valve on the oil circuit board shall not be adjusted by non-professionals at will. After adjusting the overflow valve and pressure reducing valve, pay attention to tightening the lock nut to avoid the adjusted pressure on the machine. Changes occurred in the process.

10. Detection of the nitrogen pressure of the accumulator. After the pressure oil of the accumulator is drained (see Figure 3-21 for the second fast and pressurized relief stop valve), the pressure value can be read directly from the nitrogen pressure gauge.

① Pay attention to observe whether there is any leakage of nitrogen within three days before the operation of the new machine, to prevent the internal damage of the nitrogen cylinder during the transportation of the machine.

② Do the first inspection after one week of operation, and every other week for the next two months, and then every two months thereafter. When the pressure is insufficient, nitrogen should be filled.

③ The method to check the nitrogen pressure is as follows: turn off the motor, reset the emergency stop button, turn on the shut-off valve to unload, and observe the pressure of the booster oil and the second-speed oil pressure. When the oil pressure drops to zero, the nitrogen pressure values of the two sets of accumulators are the nitrogen pressure of the booster accumulator and the nitrogen pressure of the fast injection accumulator respectively, and the nitrogen pressure must meet the specified value of the machine. For example, in the DCC500C standard horizontal cold chamber die casting machine, the nitrogen pressure of the fast injection accumulator is 90-120bar, and the nitrogen pressure of the pressurized accumulator is 90-120bar.

11. The oil temperature should be checked one hour after starting the machine. It can be read directly by a thermometer. The oil temperature must be lower than 55℃.

Link to this article: Maintenance of cooling and hydraulic system of cold chamber die casting machine

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

Sheet metal, beryllium, carbon steel, magnesium, 3D printing, precision CNC machining services for heavy equipment, construction, agriculture and hydraulic industries. Suitable for plastics and rare alloys machining. It can turn parts up to 15.7 inches in diameter. Processes include swiss machining,broaching, turning, milling, boring and threading. It also provides metal polishing, painting, surface grinding and shaft straightening services. The production range(include aluminum die casting and zinc die casting) is up to 50,000 pieces. Suitable for screw, coupling, bearing, pump, gearbox housing, drum dryer and rotary feed valve applications.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material