Residual Stress Fields and Fatigue Life in CNC-Machined Hastelloy Alloys for Hydrogen Energy Equipment

Hastelloy alloys, a family of nickel-based superalloys, are renowned for their exceptional corrosion resistance, high-temperature strength, and mechanical stability, making them ideal for demanding applications such as hydrogen energy equipment. These alloys, including Hastelloy C-276, C-22, and X, are frequently used in components like hydrogen storage tanks, pipelines, and compressors, where they are exposed to high-pressure hydrogen environments and cyclic loading. However, the performance of these components is significantly influenced by residual stress fields introduced during CNC (Computer Numerical Control) machining and their interaction with fatigue life under operational conditions.

Residual stresses are internal stresses that persist in a material after external forces are removed, often arising from manufacturing processes like machining, welding, or heat treatment. In CNC-machined Hastelloy alloys, residual stresses can be tensile or compressive, depending on machining parameters, and they play a critical role in fatigue life—the number of stress cycles a material can withstand before failure. Fatigue failure is a major concern in hydrogen energy equipment, where cyclic loading from pressure fluctuations and hydrogen embrittlement (HE) can accelerate crack initiation and propagation.

This article explores the complex relationship between residual stress fields and fatigue life in CNC-machined Hastelloy alloys, with a focus on their application in hydrogen energy systems. It examines the mechanisms of residual stress formation, their impact on fatigue behavior, the influence of hydrogen environments, and strategies for optimizing machining processes to enhance component longevity. Detailed tables are provided to compare residual stress distributions, fatigue life data, and alloy properties, offering a comprehensive resource for researchers and engineers.

Residual Stress Formation in CNC Machining

Mechanisms of Residual Stress Generation

CNC machining involves material removal through cutting, milling, or turning, which introduces thermal, mechanical, and metallurgical changes in the workpiece. Residual stresses in Hastelloy alloys arise from:

-

Thermal Gradients: High-speed machining generates localized heat, causing thermal expansion and contraction. Uneven cooling creates residual stresses, often tensile near the surface.

-

Mechanical Deformation: Cutting forces induce plastic deformation, leading to compressive stresses in the machined layer and tensile stresses in the subsurface.

-

Phase Transformations: In some alloys, machining-induced heat can trigger microstructural changes, contributing to residual stress fields.

Hastelloy alloys, with their high strength and low thermal conductivity, are particularly susceptible to thermal-induced stresses during machining. For example, Hastelloy C-276 exhibits a thermal conductivity of approximately 10.4 W/m·K at room temperature, exacerbating heat accumulation during cutting.

Measurement Techniques

Residual stresses are quantified using techniques such as:

-

X-ray Diffraction (XRD): Measures lattice strain to determine stress magnitude and direction.

-

Hole-Drilling Strain-Gauge Method: Involves drilling a small hole and measuring strain relaxation.

-

Neutron Diffraction: Provides deeper penetration for subsurface stress analysis.

Table 1 summarizes typical residual stress values in CNC-machined Hastelloy alloys, measured using XRD.

Table 1: Residual Stress in CNC-Machined Hastelloy Alloys

|

Alloy |

Machining Condition |

Surface Stress (MPa) |

Subsurface Stress (MPa) |

Depth (μm) |

Source |

|---|---|---|---|---|---|

|

Hastelloy C-276 |

Low-speed milling |

+150 (tensile) |

-50 (compressive) |

50 |

|

|

Hastelloy C-22 |

High-speed turning |

+200 (tensile) |

+100 (tensile) |

100 |

|

|

Hastelloy X |

Dry machining |

+180 (tensile) |

-30 (compressive) |

75 |

|

|

Hastelloy C-276 |

Cryogenic machining |

-100 (compressive) |

-80 (compressive) |

50 |

|

Factors Influencing Residual Stress

Key machining parameters affecting residual stress include:

-

Cutting Speed: Higher speeds increase thermal gradients, promoting tensile stresses.

-

Feed Rate: Lower feed rates reduce mechanical deformation, minimizing stress.

-

Tool Geometry: Larger nose radii induce compressive stresses, improving fatigue resistance.

-

Cooling Method: Cryogenic cooling (e.g., liquid nitrogen) reduces thermal stresses, as shown in Table 1 for Hastelloy C-276.

Fatigue Life in Hastelloy Alloys

Fatigue Mechanisms

Fatigue failure in Hastelloy alloys occurs through crack initiation, propagation, and final fracture under cyclic loading. Key factors include:

-

Microstructural Features: Grain size, phase distribution, and inclusions influence crack initiation sites.

-

Surface Integrity: Surface roughness from machining acts as stress concentrators, reducing fatigue life.

-

Residual Stresses: Compressive stresses delay crack initiation, while tensile stresses accelerate it.

Hastelloy alloys exhibit high fatigue strength due to their face-centered cubic (FCC) crystal structure, which provides multiple slip systems for plastic deformation. However, in hydrogen environments, fatigue life is compromised by hydrogen embrittlement.

Hydrogen Embrittlement Effects

Hydrogen embrittlement (HE) is a critical concern in hydrogen energy equipment, where hydrogen atoms diffuse into the metal lattice, reducing ductility and promoting brittle fracture. HE mechanisms in Hastelloy alloys include:

-

Hydrogen-Enhanced Decohesion (HEDE): Hydrogen weakens interatomic bonds, facilitating crack growth.

-

Hydrogen-Enhanced Localized Plasticity (HELP): Hydrogen increases dislocation mobility, leading to localized plastic deformation.

-

Hydride Formation: In some alloys, hydrogen forms brittle hydrides, acting as crack initiation sites.

Table 2 compares fatigue life in Hastelloy alloys with and without hydrogen exposure.

Table 2: Fatigue Life of Hastelloy Alloys in Air vs. Hydrogen Environment

|

Alloy |

Environment |

Fatigue Limit (MPa) |

Cycles to Failure (10^6) |

Reduction (%) |

Source |

|---|---|---|---|---|---|

|

Hastelloy C-276 |

Air |

450 |

10 |

- |

|

|

Hastelloy C-276 |

70 MPa H2 |

350 |

2 |

80 |

|

|

Hastelloy C-22 |

Air |

430 |

12 |

- |

|

|

Hastelloy C-22 |

70 MPa H2 |

320 |

3 |

75 |

|

|

Hastelloy X |

Air |

400 |

8 |

- |

|

|

Hastelloy X |

70 MPa H2 |

300 |

1.5 |

81 |

|

S-N Curves and Fatigue Models

Fatigue life is characterized using S-N (stress vs. number of cycles) curves, which plot cyclic stress amplitude against cycles to failure. For Hastelloy alloys, S-N curves often show a fatigue limit below which failure does not occur. However, recent studies suggest that even small stress amplitudes can cause failure in hydrogen environments due to HE.

Fatigue life prediction models include:

-

Paris Law: Describes crack growth rate as a function of stress intensity factor range.

-

Goodman Relation: Accounts for mean stress effects on fatigue strength.

-

Palmgren-Miner Rule: Estimates cumulative damage under variable loading.

These models are adapted for hydrogen environments by incorporating HE parameters, such as hydrogen concentration and diffusion coefficients.

Interaction Between Residual Stress and Fatigue Life

Compressive vs. Tensile Residual Stresses

Compressive residual stresses enhance fatigue life by closing crack tips and reducing stress intensity factors. In contrast, tensile residual stresses promote crack initiation and propagation, reducing fatigue life. For example, cryogenic machining of Hastelloy C-276 induces compressive stresses (-100 MPa), increasing fatigue life by up to 20% compared to dry machining (+150 MPa).

Stress Relaxation and Redistribution

Under cyclic loading, residual stresses may relax or redistribute due to plastic deformation or thermal effects. In hydrogen environments, hydrogen diffusion accelerates stress relaxation, complicating fatigue life predictions.

Case Studies

-

Hydrogen Storage Tanks: CNC-machined Hastelloy C-276 components in Type III hydrogen storage tanks exhibit tensile residual stresses (+200 MPa) from high-speed machining, reducing fatigue life by 50% in 70 MPa hydrogen environments.

-

Pipelines: Shot-peened Hastelloy C-22 pipelines with compressive residual stresses (-150 MPa) show a 30% increase in fatigue life under cyclic pressure loading.

Table 3 summarizes the impact of residual stress on fatigue life in specific applications.

Table 3: Impact of Residual Stress on Fatigue Life in Hydrogen Energy Equipment

|

Component |

Alloy |

Residual Stress (MPa) |

Fatigue Life (Cycles, 10^6) |

Environment |

Source |

|---|---|---|---|---|---|

|

Storage Tank |

Hastelloy C-276 |

+200 (tensile) |

2 |

70 MPa H2 |

|

|

Storage Tank |

Hastelloy C-276 |

-100 (compressive) |

4 |

70 MPa H2 |

|

|

Pipeline |

Hastelloy C-22 |

-150 (compressive) |

15 |

Air |

|

|

Compressor |

Hastelloy X |

+180 (tensile) |

1.5 |

50 MPa H2 |

|

Optimization Strategies for CNC Machining

Machining Parameter Optimization

To minimize tensile residual stresses and enhance fatigue life, machining parameters should be optimized:

-

Low Cutting Speeds: Reduce thermal gradients.

-

High Feed Rates: Minimize mechanical deformation.

-

Cryogenic Cooling: Induce compressive stresses.

-

Tool Coatings: Reduce friction and heat generation.

Post-Machining Treatments

Post-machining treatments can mitigate residual stresses:

-

Shot Peening: Introduces compressive stresses, improving fatigue life by 25–50%.

-

Stress Relieving: Heat treatment at 900–1,300°F reduces residual stresses without altering mechanical properties.

-

Hot Isostatic Pressing (HIP): Closes internal defects, enhancing fatigue resistance.

Advanced Modeling and Simulation

Finite element analysis (FEA) and crystal plasticity finite element method (CPFEM) are used to predict residual stress distributions and fatigue life. These models incorporate machining parameters, material properties, and hydrogen effects, enabling process optimization.

Material Properties of Hastelloy Alloys

Hastelloy alloys vary in composition and properties, influencing their response to machining and fatigue. Table 4 compares key properties relevant to residual stress and fatigue life.

Table 4: Properties of Hastelloy Alloys Used in Hydrogen Energy Equipment

|

Alloy |

Composition (Major Elements) |

Yield Strength (MPa) |

Thermal Conductivity (W/m·K) |

Hydrogen Solubility (ppm) |

Source |

|---|---|---|---|---|---|

|

Hastelloy C-276 |

Ni, Mo, Cr, Fe |

350 |

10.4 |

50 |

|

|

Hastelloy C-22 |

Ni, Mo, Cr, Fe, W |

365 |

11.1 |

45 |

|

|

Hastelloy X |

Ni, Cr, Fe, Mo |

310 |

9.2 |

60 |

|

Challenges and Future Directions

Challenges

-

Hydrogen Embrittlement Modeling: Accurate prediction of HE effects on fatigue life remains challenging due to complex hydrogen-material interactions.

-

Residual Stress Measurement: Non-destructive techniques like neutron diffraction are costly and limited in accessibility.

-

Scalability: Optimizing machining parameters for large-scale production is resource-intensive.

Future Directions

-

Machine Learning: Develop predictive models for residual stress and fatigue life using big data and machine learning.

-

Advanced Alloys: Explore high-entropy alloys with enhanced HE resistance.

-

Hybrid Manufacturing: Combine additive manufacturing and CNC machining to control residual stresses.

Conclusion

The relationship between residual stress fields and fatigue life in CNC-machined Hastelloy alloys is critical for ensuring the reliability of hydrogen energy equipment. Tensile residual stresses from machining accelerate fatigue failure, particularly in hydrogen environments, while compressive stresses enhance longevity. Optimizing machining parameters, applying post-machining treatments, and leveraging advanced modeling can mitigate these effects. Continued research into hydrogen embrittlement, non-destructive stress measurement, and novel alloys will further improve the performance of Hastelloy components in hydrogen energy systems.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

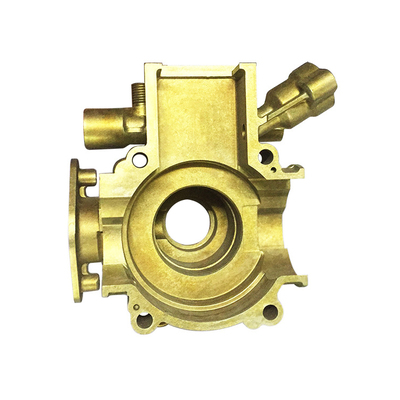

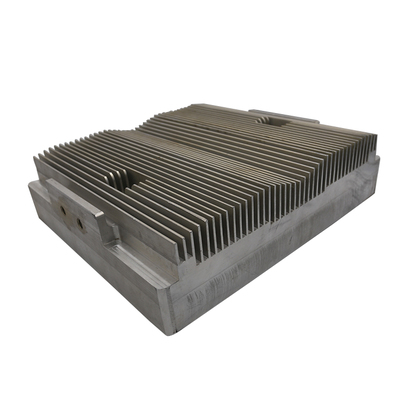

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material