Recent Advances in Polyamide-Based Materials for the Automotive Industry

Polyamides (PAs), commonly referred to as nylons, are a class of high-performance thermoplastic polymers characterized by the presence of amide linkages in their molecular structure. These materials are renowned for their excellent mechanical properties, thermal stability, chemical resistance, and versatility, making them a cornerstone in the automotive industry. Polyamides, particularly polyamide 6 (PA6), polyamide 66 (PA66), polyamide 12 (PA12), and specialty polyamides like polyphthalamide (PPA) and polyamide-imide (PAI), have been extensively utilized in automotive applications due to their ability to meet stringent performance requirements while contributing to lightweighting, fuel efficiency, and sustainability goals.

The automotive industry is undergoing a transformative period driven by the need to reduce greenhouse gas emissions, enhance fuel efficiency, and transition to electric vehicles (EVs). Polyamide-based materials have emerged as critical enablers in this transformation, replacing traditional materials like steel and aluminum in various components. Recent advances in polyamide technology, including the development of bio-based and recycled feedstocks, reinforcement with advanced fibers, and improvements in manufacturing processes, have further expanded their applicability. This article provides a comprehensive review of these advancements, focusing on the properties, processing, applications, and future potential of polyamide-based materials in the automotive sector. Detailed tables are included to compare key properties and applications, providing a scientific foundation for understanding their role in modern automotive engineering.

2. Background and Properties of Polyamide-Based Materials

2.1 Chemical Structure and Classification

Polyamides are polymers characterized by repeating amide bonds (-CONH-) in their backbone. They can be classified into two main categories: aliphatic polyamides (e.g., PA6, PA66, PA12) and aromatic or semi-aromatic polyamides (e.g., PPA, PAI). Aliphatic polyamides are derived from the polymerization of amino acids or lactams (e.g., caprolactam for PA6) or the condensation of diamines and dicarboxylic acids (e.g., hexamethylenediamine and adipic acid for PA66). Aromatic polyamides, such as PPA and PAI, incorporate aromatic rings, enhancing thermal and mechanical performance but increasing processing complexity.

The molecular structure of polyamides imparts a semi-crystalline morphology, contributing to their high strength, toughness, and thermal stability. The degree of crystallinity, influenced by processing conditions and additives, significantly affects their mechanical and thermal properties. For instance, PA6 and PA66 exhibit higher crystallinity than PA12, leading to greater stiffness but lower flexibility. Specialty polyamides like PPA and PAI offer superior performance in high-temperature environments, making them suitable for demanding automotive applications.

2.2 Key Properties Relevant to Automotive Applications

Polyamides are valued in the automotive industry for their unique combination of properties, which include:

-

Mechanical Strength: Polyamides exhibit high tensile strength and toughness, making them suitable for structural components and safety-critical parts. For example, PA66 has a tensile strength of approximately 80-100 MPa in its unreinforced form, which can increase significantly with fiber reinforcement.

-

Thermal Stability: Polyamides maintain their properties at elevated temperatures, with PA66 and PPA withstanding continuous use temperatures up to 150°C and 200°C, respectively. PAI can endure temperatures up to 274°C, ideal for under-hood applications.

-

Chemical Resistance: Polyamides resist degradation from automotive fluids such as oils, fuels, and coolants, ensuring durability in harsh environments.

-

Abrasion Resistance: The wear resistance of polyamides makes them suitable for components like gears and bearings, which experience repeated mechanical stress.

-

Lightweighting Potential: With densities ranging from 1.1 to 1.4 g/cm³ (compared to 7.8 g/cm³ for steel), polyamides significantly reduce vehicle weight, enhancing fuel efficiency and reducing emissions.

-

Recyclability: Advances in chemical and mechanical recycling have improved the sustainability of polyamide-based materials, aligning with circular economy principles.

2.3 Challenges and Limitations

Despite their advantages, polyamides face challenges that must be addressed to maximize their potential in automotive applications. One significant limitation is their hygroscopic nature, as polyamides tend to absorb water, which can reduce tensile strength and dimensional stability. For instance, PA6 and PA66 can absorb up to 8-10% water by weight, necessitating careful drying before processing. Additionally, the high cost of specialty polyamides like PPA and PAI can limit their adoption in cost-sensitive applications. Processing complexities, such as the need for precise temperature control to prevent oxidation, also pose challenges.

3. Advances in Polyamide Formulations

3.1 Reinforcement with Advanced Fibers

One of the most significant advancements in polyamide-based materials is the incorporation of reinforcing fibers, such as glass fibers (GF), carbon fibers (CF), and aramid fibers, to enhance mechanical and thermal properties. These reinforcements increase stiffness, strength, and impact resistance, making polyamide composites viable for structural and safety-critical components.

-

Glass Fiber Reinforcement: Glass fiber-reinforced polyamides (PA-GF) are widely used due to their cost-effectiveness and significant improvement in mechanical properties. For example, PA6 reinforced with 30% glass fiber (PA6-GF30) exhibits a tensile strength of approximately 150-180 MPa and a modulus of elasticity of 8-10 GPa, compared to 80 MPa and 3 GPa for unreinforced PA6. These composites are commonly used in components like intake manifolds, door handles, and structural brackets.

-

Carbon Fiber Reinforcement: Carbon fiber-reinforced polyamides (PA-CF) offer superior strength-to-weight ratios, making them ideal for lightweighting applications. PA6-CF composites with 47% carbon fiber content have shown tensile strengths exceeding 200 MPa and improved thermal stability compared to neat PA6. These materials are increasingly used in EV battery enclosures and structural components.

-

Aramid Fiber Reinforcement: Aramid fibers enhance impact resistance and vibration damping, making them suitable for components like engine mounts and suspension parts. However, their high cost limits widespread adoption.

3.2 Bio-Based and Recycled Polyamide Resins

The automotive industry’s focus on sustainability has driven the development of bio-based and recycled polyamide resins. These materials reduce reliance on fossil fuel-based feedstocks and support a circular economy.

-

Bio-Based Polyamides: Bio-based polyamides, such as PA11 derived from castor oil, offer comparable performance to petroleum-based polyamides while reducing carbon footprints. For example, Arkema’s Rilsan® PA11 is used in fuel lines and air brake systems due to its flexibility and chemical resistance. Recent advancements have expanded the use of bio-based PA6 and PA66, with companies like BASF developing grades with up to 50% bio-based content.

-

Recycled Polyamides: Recycled polyamides, such as RadiciGroup’s Renycle, utilize post-industrial and post-consumer waste to produce high-performance materials. Marelli’s award-winning intake manifold, made from fully recycled PA66, reduces CO2 emissions by 70% compared to virgin materials. These advancements align with regulatory mandates and consumer demand for sustainable automotive components.

3.3 High-Temperature and Flame-Retardant Polyamides

The rise of electric vehicles and high-performance internal combustion engines has increased demand for polyamides with enhanced thermal and flame-retardant properties.

-

High-Temperature Polyamides: Specialty polyamides like PPA and PAI are engineered to withstand extreme temperatures and mechanical stress. For instance, Solvay’s Amodel® PPA is used in turbocharger housings and exhaust components, maintaining dimensional stability at temperatures up to 200°C. PAI, with a glass transition temperature (Tg) of approximately 280°C, is employed in cam sprockets and fuel system components.

-

Flame-Retardant Polyamides: Flame-retardant polyamides, such as SABIC’s STAMAX™ 30YH570, are critical for EV battery enclosures, where they prevent thermal runaway and suppress fire propagation. These materials incorporate additives like halogen-free flame retardants to meet safety standards like UL 2596, ensuring compliance with stringent automotive regulations.

3.4 Smart Polymers and Functional Additives

Emerging smart polymers, such as shape memory polymers (SMPs) and conductive polyamides, are expanding the functional capabilities of polyamide-based materials.

-

Shape Memory Polymers: SMPs, which change shape in response to stimuli like temperature, are being explored for adaptive aerodynamics and self-healing coatings. For example, researchers in China and the Netherlands have developed self-healing shape memory composite coatings using PA6, enhancing durability and reducing maintenance costs.

-

Conductive Polyamides: Conductive polyamides, incorporating additives like carbon nanotubes or graphene, are used in electrical connectors and EMI shielding components. These materials support the electrification trend by enabling lightweight, high-performance electronic systems.

4. Manufacturing Processes for Polyamide-Based Materials

4.1 Traditional Processing Techniques

Polyamide-based materials are processed using a variety of techniques, each tailored to specific automotive applications. Key methods include:

-

Injection Molding: Injection molding is the most common method for producing polyamide components, such as door handles, gears, and intake manifolds. It offers high precision and repeatability, with cycle times as low as 30-60 seconds for PA6 and PA66 parts. However, careful control of processing parameters, such as melt temperature (250-300°C) and mold temperature (80-100°C), is required to prevent defects.

-

Extrusion: Extrusion is used to manufacture continuous profiles, such as fuel lines and air ducts, from PA12 and PA6. Recent advancements in extrusion technology have improved dimensional accuracy and reduced material waste, making it cost-effective for high-volume production.

-

Resin Transfer Molding (RTM): RTM is increasingly used for fiber-reinforced polyamide composites, particularly PA6-CF and PA6-GF. This process enables the production of complex shapes with high fiber content, as demonstrated by Zaldua et al. in their study of PA6/CF composites with 47% carbon fiber content.

4.2 Additive Manufacturing

Additive manufacturing (AM), or 3D printing, has revolutionized the production of polyamide-based components, offering design flexibility and reduced lead times.

-

Selective Laser Sintering (SLS): SLS is widely used for PA12 and PA6, enabling the production of complex geometries without the need for molds. For example, hollow glass-filled PA12 composites produced via SLS exhibit improved mechanical properties and reduced weight, making them suitable for prototyping and low-volume production.

-

Fused Deposition Modeling (FDM): FDM with PA-CF filaments is gaining traction for producing structural components, such as brackets and battery trays. Advances in filament quality have improved surface finish and mechanical performance, bridging the gap between prototyping and production.

4.3 Machining and Post-Processing

Machining is often required to achieve precise tolerances in polyamide composites, particularly for CF and GF-reinforced parts. However, challenges such as tool wear and surface delamination necessitate specialized techniques, such as cryogenic machining and laser-assisted cutting. Recent studies have shown that machining PA-based composites at lower production volumes can be more economical than molding, reducing costs by up to 20% for certain components.

5. Applications of Polyamide-Based Materials in the Automotive Industry

5.1 Under-the-Hood Components

Polyamides are extensively used in under-the-hood applications due to their thermal stability and chemical resistance. Key components include:

-

Intake Manifolds: PA66-GF is the material of choice for intake manifolds, reducing weight by up to 60% compared to cast iron. Ford’s use of PA66 in air intake manifolds exemplifies this trend, improving fuel efficiency and emissions performance.

-

Turbocharger Housings: PPA and PAI are used in turbocharger housings, withstanding temperatures up to 200°C and high mechanical stress. Solvay’s Amodel® PPA has been adopted by major OEMs for its dimensional stability and fatigue resistance.

-

Fuel System Components: PA12 and bio-based PA11 are used in fuel lines and connectors due to their flexibility and resistance to hydrocarbons. Radiation-crosslinked PA12, as studied by Hıdıroğlu et al., enhances pressure-impact strength in fuel transfer pipelines.

5.2 Exterior Components

Polyamide-based materials are increasingly used in exterior components, where they provide durability, aesthetics, and lightweighting benefits.

-

Door Handles and Mirrors: PA6 is commonly used for door handles and mirrors due to its toughness and surface finish. Glass fiber reinforcement enhances rigidity, reducing deformation under load.

-

Wheel Covers: PA6-GF and PA66-GF are used in wheel covers, offering a balance of strength and weight reduction. These components contribute to improved aerodynamics and fuel efficiency.

-

Bumpers and Grilles: Polyamide composites, such as PA6-CF, are used in bumpers and grilles, providing impact resistance and design flexibility.

5.3 Interior Components

Polyamides enhance the aesthetics, comfort, and safety of vehicle interiors.

-

Dashboards and Panels: PA6 and PA66 are used in dashboards and interior panels, often reinforced with glass fibers to improve stiffness. Conductive polyamides are employed in electronic control units (ECUs) to provide EMI shielding.

-

Airbag Containers: PA6 and PA12 are used in airbag containers due to their high impact resistance and dimensional stability. These materials ensure reliable deployment in crash scenarios.

-

Seating Components: Polyamide composites, such as PA6-GF, are used in seat frames, reducing weight while maintaining structural integrity.

5.4 Electric Vehicle Applications

The rise of electric vehicles has expanded the use of polyamide-based materials in battery and powertrain systems.

-

Battery Enclosures: PA6-CF and flame-retardant PA66, such as SABIC’s STAMAX™ 30YH570, are used in EV battery enclosures to provide thermal insulation and fire resistance. These materials reduce weight by up to 40% compared to metallic enclosures.

-

Electrical Connectors: High-performance polyamides like PPA and PAI are used in electrical connectors and control units, offering high dielectric strength and thermal stability.

-

Cooling Systems: PA12 and PA6 are used in cooling hoses and thermal management systems, ensuring efficient heat dissipation in EV powertrains.

6. Sustainability and Recyclability

6.1 Recycling Technologies

The recyclability of polyamides is a critical factor in their adoption, given the automotive industry’s focus on sustainability. Advances in recycling technologies have improved the feasibility of reusing polyamide-based materials.

-

Mechanical Recycling: Mechanical recycling involves grinding and reprocessing polyamide waste into pellets. Recycled PA6 and PA66 retain up to 90% of their original mechanical properties when properly processed, making them suitable for non-critical components like wheel covers.

-

Chemical Recycling: Chemical recycling, such as ring-closing depolymerization, breaks down polyamides into monomers for repolymerization. Studies by Alberti et al. have demonstrated the feasibility of recycling PA6 via this method, achieving high-purity monomers for virgin-quality resin production.

-

Thermocatalytic Recycling: Thermocatalytic routes, as explored by Lee et al., enable the conversion of polyamide waste into valuable chemicals, reducing landfill waste and supporting a circular economy.

6.2 Environmental Impact and Regulatory Compliance

Polyamide-based materials contribute to environmental sustainability by reducing vehicle weight and emissions. For example, replacing steel components with PA6-GF can reduce CO2 emissions by up to 10% over a vehicle’s lifecycle. Regulatory frameworks, such as Europe’s 2030 carbon emission targets and China’s Corporate Average Fuel Consumption (CAFC) standards, have driven the adoption of lightweight polyamides. Additionally, the use of bio-based and recycled polyamides aligns with global mandates for sustainable manufacturing practices.

7. Comparative Analysis of Polyamide-Based Materials

The following tables provide a detailed comparison of polyamide-based materials used in the automotive industry, focusing on their properties, applications, and performance metrics.

Table 1: Comparison of Polyamide Types and Properties

|

Polyamide Type |

Density (g/cm³) |

Tensile Strength (MPa) |

Modulus of Elasticity (GPa) |

Continuous Use Temperature (°C) |

Key Characteristics |

|---|---|---|---|---|---|

|

PA6 |

1.14 |

80-100 |

3-4 |

120-150 |

High toughness, good abrasion resistance |

|

PA66 |

1.14 |

80-100 |

3-4 |

120-150 |

High stiffness, excellent thermal stability |

|

PA12 |

1.01 |

50-70 |

1-2 |

100-120 |

High flexibility, low water absorption |

|

PPA |

1.2-1.4 |

100-150 |

4-6 |

180-200 |

Superior thermal and chemical resistance |

|

PAI |

1.4-1.45 |

150-200 |

5-7 |

250-274 |

Exceptional strength at high temperatures |

|

PA6-GF30 |

1.35 |

150-180 |

8-10 |

150-180 |

Enhanced stiffness and strength |

|

PA6-CF47 |

1.4 |

200-250 |

15-20 |

150-180 |

High strength-to-weight ratio |

Table 2: Applications of Polyamide-Based Materials in Automotive Components

|

Component |

Polyamide Type |

Reinforcement |

Key Benefits |

Examples of Use |

|---|---|---|---|---|

|

Intake Manifolds |

PA66 |

Glass Fiber |

Lightweight, thermal stability |

Ford vehicles |

|

Turbocharger Housings |

PPA |

None/CF |

High-temperature resistance |

BMW, Mercedes-Benz |

|

Fuel Lines |

PA12, PA11 |

None |

Chemical resistance, flexibility |

Volkswagen, Toyota |

|

Battery Enclosures |

PA6, PA66 |

Carbon Fiber |

Flame resistance, lightweight |

Tesla, Hyundai |

|

Door Handles |

PA6 |

Glass Fiber |

Toughness, aesthetic finish |

General Motors |

|

Electrical Connectors |

PPA, PAI |

None/CF |

High dielectric strength |

Nissan, Renault |

|

Airbag Containers |

PA6, PA12 |

None |

Impact resistance |

Honda, Ford |

Table 3: Environmental Impact of Polyamide-Based Materials

|

Material Type |

CO2 Emission Reduction (%) |

Recyclability |

Bio-Based Option |

Regulatory Compliance |

|---|---|---|---|---|

|

PA6-GF |

8-10 |

High |

Partial (up to 50%) |

EU 2030, CAFC |

|

PA66-GF |

8-10 |

High |

Partial (up to 50%) |

EU 2030, CAFC |

|

PA12 |

5-7 |

Moderate |

Yes (PA11) |

EU 2030, CAFC |

|

PPA |

6-8 |

Moderate |

Limited |

EU 2030, CAFC |

|

PAI |

5-7 |

Low |

None |

EU 2030, CAFC |

|

Recycled PA66 (Renycle) |

70 |

High |

None |

EU 2030, CAFC |

8. Future Trends and Opportunities

8.1 Electric Vehicle Market Expansion

The global shift toward electric vehicles is a major driver for polyamide-based materials. As EV production is projected to reach 30% of total vehicle production by 2030, polyamides will play a critical role in battery enclosures, thermal management systems, and electrical components. Innovations in flame-retardant and conductive polyamides will further enhance their suitability for EV applications.

8.2 Sustainability and Circular Economy

The development of bio-based and recycled polyamides will continue to gain momentum, driven by regulatory pressures and consumer demand. Companies like BASF, Arkema, and RadiciGroup are investing in sustainable polyamide solutions, with goals to achieve carbon neutrality by 2050. Advances in chemical recycling technologies will further improve the recyclability of polyamides, reducing waste and environmental impact.

8.3 Integration with Smart Technologies

The integration of smart polymers and functional additives will expand the functionality of polyamide-based materials. For example, conductive polyamides with embedded sensors could enable real-time monitoring of component performance, enhancing vehicle safety and efficiency. Shape memory polymers may find applications in adaptive aerodynamics and self-healing surfaces, reducing maintenance costs.

8.4 Advanced Manufacturing Techniques

Continued advancements in additive manufacturing and composite processing will enhance the efficiency and scalability of polyamide-based materials. Techniques like automated fiber placement (AFP) and high-speed RTM will enable the production of complex, lightweight components at lower costs, supporting the automotive industry’s demand for high-volume production.

9. Challenges and Research Directions

9.1 Addressing Hygroscopicity

The water absorption properties of polyamides remain a challenge, particularly for PA6 and PA66. Research is ongoing to develop hydrophobic additives and coatings that reduce moisture uptake without compromising mechanical properties. For example, nanotechnology-based coatings have shown promise in reducing water absorption by up to 50%.

9.2 Cost Reduction

The high cost of specialty polyamides and advanced composites limits their adoption in mass-market vehicles. Research efforts are focused on developing cost-effective synthesis methods and scaling up recycling processes to reduce material costs. For instance, improvements in chemical recycling could lower the cost of recycled PA6 by 20-30%.

9.3 Enhancing Recyclability

While mechanical and chemical recycling have advanced, challenges remain in achieving high-purity recycled polyamides for critical applications. Future research will focus on developing catalysts and processes that improve the efficiency of chemical recycling, enabling the production of virgin-quality resins from mixed waste streams.

10. Conclusion

Polyamide-based materials have become indispensable in the automotive industry, offering a unique combination of mechanical strength, thermal stability, and lightweighting potential. Recent advances in fiber reinforcement, bio-based and recycled feedstocks, high-temperature formulations, and smart polymers have expanded their applications, from under-the-hood components to EV battery enclosures. The integration of advanced manufacturing techniques, such as additive manufacturing and resin transfer molding, has further enhanced their versatility and cost-effectiveness. As the automotive industry continues to prioritize sustainability, performance, and electrification, polyamide-based materials will play a pivotal role in shaping the future of mobility. Ongoing research to address challenges like hygroscopicity and cost will further solidify their position as a cornerstone of automotive engineering.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

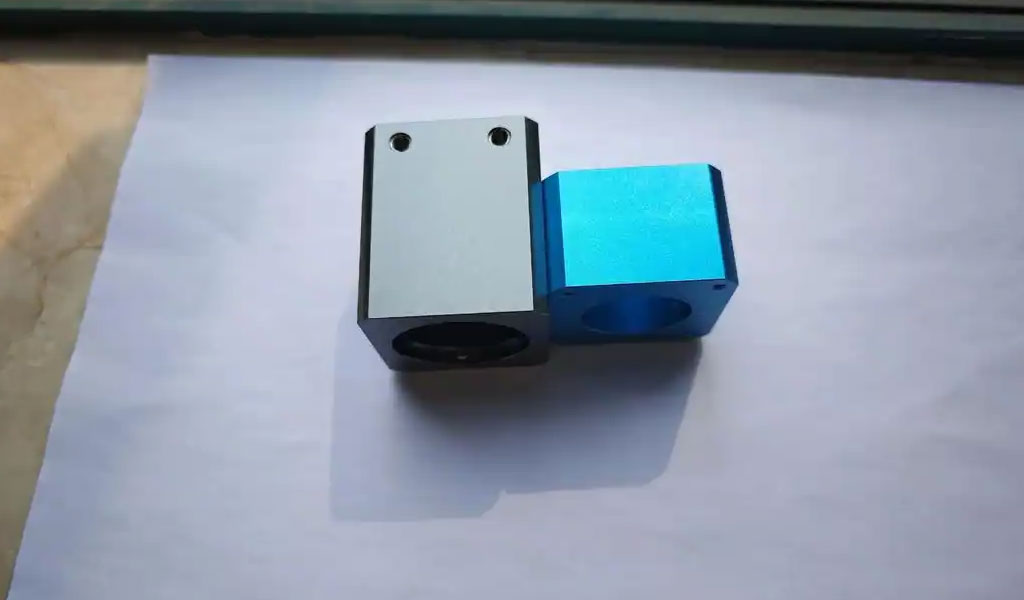

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material