High-performance Numerical Control for High-speed Machining Using Polynomial Trajectories

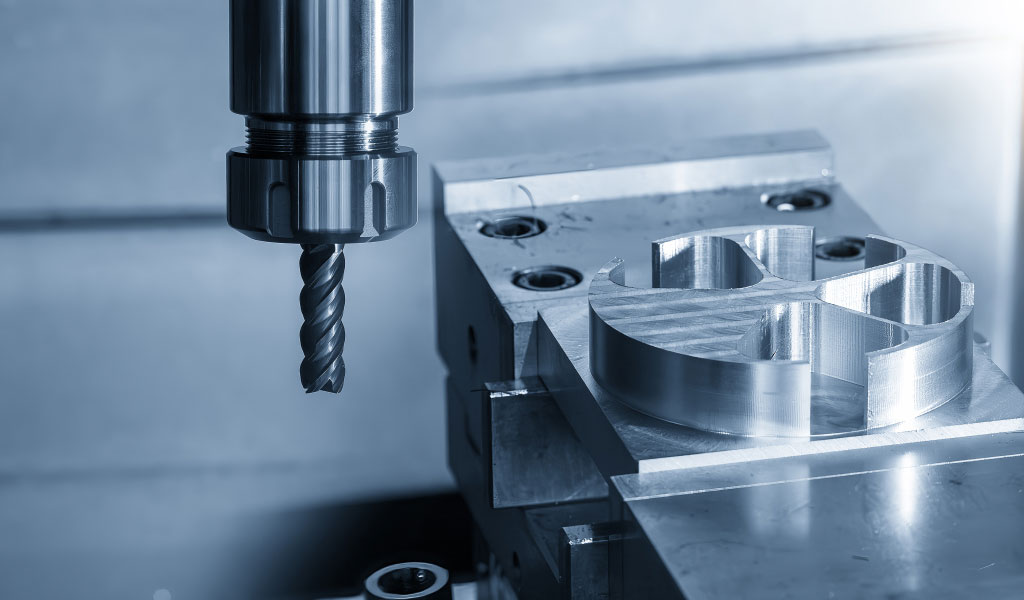

High-performance numerical control (NC) systems are integral to modern manufacturing, particularly in high-speed machining (HSM), where precision, efficiency, and speed are paramount. HSM involves the rapid removal of material from a workpiece using cutting tools operating at elevated spindle speeds and feed rates, typically in the range of 10,000 to 100,000 RPM and feed rates exceeding 20 m/min. The adoption of polynomial trajectories in NC systems has revolutionized HSM by enabling smoother tool paths, reduced machining times, and enhanced surface quality. This article explores the principles, methodologies, and technologies underlying high-performance NC systems for HSM, with a particular focus on the application of polynomial trajectories. It provides a comprehensive analysis of the mathematical foundations, control algorithms, and practical implementations, supported by detailed tables comparing various approaches.

High-speed machining is employed across industries such as aerospace, automotive, and mold-making, where complex geometries and tight tolerances are common. Traditional NC systems, which rely on linear or circular interpolation, often struggle to maintain accuracy and efficiency at high speeds due to discontinuities in tool paths and limitations in controller response times. Polynomial trajectories, particularly those based on spline interpolation (e.g., B-splines, NURBS), address these challenges by providing smooth, continuous tool paths that minimize vibrations, reduce tool wear, and optimize machining dynamics. This article delves into the theoretical and practical aspects of polynomial-based NC systems, offering insights into their advantages, limitations, and future potential.

Fundamentals of High-speed Machining

High-speed machining is characterized by high spindle speeds, rapid feed rates, and shallow depths of cut, which collectively enable faster material removal rates (MRR) while maintaining precision. HSM is distinct from conventional machining due to its emphasis on dynamic performance, thermal management, and tool stability. The key components of HSM include the machine tool, cutting tool, workpiece material, and the NC system, which orchestrates the entire process.

Key Characteristics of HSM

-

Spindle Speed: Typically ranges from 10,000 to 100,000 RPM, depending on the material and tool.

-

Feed Rate: Can exceed 20 m/min, requiring precise control to avoid chatter or deflection.

-

Depth of Cut: Shallow cuts (0.1–1 mm) to minimize heat generation and tool wear.

-

Surface Finish: HSM achieves superior surface quality, often eliminating the need for secondary finishing processes.

HSM is particularly suited for materials such as aluminum, titanium, and hardened steels, where high MRR and surface quality are critical. However, the high velocities and accelerations involved introduce challenges such as increased tool wear, thermal deformation, and dynamic instability, necessitating advanced NC systems.

Role of NC Systems in HSM

Numerical control systems serve as the brain of HSM operations, translating computer-aided design (CAD) models into machine instructions via computer-aided manufacturing (CAM) software. The NC system interprets these instructions to control the machine’s axes, spindle, and auxiliary functions. In HSM, the NC system must:

-

Process complex tool paths rapidly.

-

Maintain high accuracy at elevated speeds.

-

Minimize vibrations and jerk (rate of change of acceleration).

-

Ensure real-time adaptability to dynamic conditions.

Traditional NC systems, which rely on G-code instructions for linear (G01) or circular (G02/G03) interpolation, often produce segmented tool paths that lead to discontinuities in velocity and acceleration. These discontinuities cause vibrations, reduce tool life, and degrade surface quality. Polynomial trajectories, particularly splines, overcome these limitations by providing smooth, continuous paths that optimize machine dynamics.

Polynomial Trajectories in NC Systems

Polynomial trajectories refer to tool paths defined by polynomial functions, typically splines or non-uniform rational B-splines (NURBS), which allow for smooth, continuous motion. Unlike linear or circular interpolation, polynomial trajectories can represent complex geometries with fewer control points, reducing computational overhead and improving path accuracy.

Mathematical Foundations

Polynomial trajectories are based on parametric curves, where the tool’s position is defined as a function of a parameter ( u ), typically ranging from 0 to 1. A polynomial curve in 3D space can be expressed as: [ \mathbf{P}(u) = (x(u), y(u), z(u)) ] where ( x(u) ), ( y(u) ), and ( z(u) ) are polynomial functions of degree ( n ). Common forms include:

-

Cubic Polynomials: Degree 3 polynomials, offering a balance between flexibility and computational efficiency.

-

B-splines: Piecewise polynomials defined by control points and knot vectors, ensuring continuity in position, velocity, and acceleration.

-

NURBS: Non-uniform rational B-splines, which extend B-splines by incorporating weights to represent conic sections and freeform geometries accurately.

The general form of a B-spline curve is: [ \mathbf{C}(u) = \sum_{i=0}^{n} \mathbf{P}i N{i,k}(u) ] where:

-

( \mathbf{P}_i ): Control points.

-

( N_{i,k}(u) ): B-spline basis functions of degree ( k ).

-

( u ): Parameter along the curve.

NURBS extend this by introducing weights ( w_i ): [ \mathbf{C}(u) = \frac{\sum_{i=0}^{n} \mathbf{P}i w_i N{i,k}(u)}{\sum_{i=0}^{n} w_i N_{i,k}(u)} ] NURBS are widely used in CAD/CAM systems due to their ability to represent both freeform and analytical shapes (e.g., circles, ellipses) with high precision.

Advantages of Polynomial Trajectories

-

Smoothness: Ensure continuous velocity and acceleration, reducing jerk and vibrations.

-

Compact Representation: Require fewer control points than linear segments, reducing data storage and processing requirements.

-

Flexibility: Can represent complex geometries, including freeform surfaces and intricate contours.

-

Improved Dynamics: Minimize sudden changes in tool motion, enhancing machine stability and tool life.

Implementation in NC Systems

In high-performance NC systems, polynomial trajectories are implemented through:

-

CAD/CAM Integration: CAD software generates polynomial curves (e.g., NURBS) to represent the workpiece geometry. CAM software converts these into tool paths.

-

Interpolation: The NC controller interpolates the polynomial trajectory in real-time, calculating intermediate points to guide the tool.

-

Look-ahead Algorithms: Anticipate upcoming path segments to optimize feed rates and avoid overshooting or oscillations.

-

Feedback Control: Use high-resolution encoders and sensors to ensure the tool follows the prescribed trajectory accurately.

Control Algorithms for Polynomial Trajectories

The effectiveness of polynomial trajectories in HSM depends on sophisticated control algorithms that ensure precise tracking, minimize errors, and optimize machining parameters. Key algorithms include:

Real-time Interpolation

Real-time interpolation involves computing tool positions along the polynomial trajectory at regular intervals (e.g., every 1–2 ms). For a NURBS curve, the controller evaluates ( \mathbf{C}(u) ) at discrete values of ( u ), ensuring smooth motion. The interpolation algorithm must account for:

-

Chordal Error: The deviation between the interpolated path and the ideal curve, which must be kept within tolerances (e.g., 1–10 µm).

-

Feed Rate Scheduling: Adjust the feed rate based on curvature, machine dynamics, and material properties to avoid excessive forces or vibrations.

-

Kinematic Constraints: Respect the machine’s maximum velocity, acceleration, and jerk limits.

A common interpolation method is the Taylor series expansion, where the parameter ( u ) is updated iteratively: [ u_{i+1} = u_i + \frac{v \Delta t}{|\mathbf{C}'(u_i)|} ] where:

-

( v ): Desired feed rate.

-

( \Delta t ): Interpolation time step.

-

( \mathbf{C}'(u) ): First derivative of the curve (tangent vector).

Look-ahead Control

Look-ahead algorithms analyze upcoming path segments to optimize feed rates and avoid abrupt changes in motion. For polynomial trajectories, look-ahead involves:

-

Curvature Analysis: Identify regions of high curvature (e.g., tight corners), where feed rates must be reduced to maintain accuracy.

-

Jerk Limitation: Ensure the rate of change of acceleration remains within acceptable limits to minimize vibrations.

-

Path Smoothing: Blend polynomial segments to eliminate discontinuities at junctions.

Feedback and Feedforward Control

High-performance NC systems combine feedback and feedforward control to achieve precise trajectory tracking:

-

Feedback Control: Uses real-time sensor data (e.g., encoder feedback) to correct deviations from the desired path. Proportional-integral-derivative (PID) controllers are commonly employed.

-

Feedforward Control: Anticipates errors based on the machine’s dynamic model, compensating for delays and inertia before they occur.

Adaptive Control

Adaptive control adjusts machining parameters (e.g., feed rate, spindle speed) in real-time based on sensor feedback, such as cutting forces or tool temperature. For polynomial trajectories, adaptive control ensures:

-

Thermal Stability: Compensates for thermal expansion of the tool or workpiece.

-

Tool Wear Compensation: Adjusts the tool path to account for wear-induced deviations.

-

Vibration Suppression: Detects and mitigates chatter through feed rate modulation or spindle speed variation.

Hardware Requirements for High-performance NC

High-speed machining with polynomial trajectories demands robust hardware capable of processing complex calculations and delivering precise motion control. Key hardware components include:

CNC Controllers

Modern CNC controllers for HSM feature:

-

High-speed Processors: Multi-core processors or field-programmable gate arrays (FPGAs) for real-time interpolation and control.

-

Large Memory: To store complex polynomial tool paths and look-ahead buffers.

-

High-bandwidth Communication: EtherCAT or similar protocols for rapid data exchange between the controller and machine axes.

Machine Tools

HSM machine tools are designed for rigidity and dynamic performance:

-

Spindle: High-speed spindles (10,000–100,000 RPM) with active cooling to manage heat.

-

Linear Motors: Provide high acceleration and precision compared to traditional ball screws.

-

Vibration Damping: Advanced materials and designs to minimize chatter and ensure stability.

Sensors and Feedback Systems

-

Encoders: High-resolution linear or rotary encoders for precise position feedback.

-

Force Sensors: Monitor cutting forces to detect tool wear or chatter.

-

Thermal Sensors: Measure tool and workpiece temperatures to compensate for thermal expansion.

Comparison of Polynomial Trajectories with Traditional Methods

The following tables compare polynomial trajectories (e.g., NURBS) with traditional linear and circular interpolation methods in terms of key performance metrics.

Table 1: Comparison of Tool Path Characteristics

|

Metric |

Linear Interpolation |

Circular Interpolation |

Polynomial Trajectories (NURBS) |

|---|---|---|---|

|

Path Smoothness |

Discontinuous at segment junctions |

Continuous within arcs, discontinuous at junctions |

Continuous in position, velocity, and acceleration |

|

Data Size |

High (many segments for complex shapes) |

Moderate (fewer segments for arcs) |

Low (compact representation) |

|

Computational Load |

Low (simple calculations) |

Moderate (arc calculations) |

High (complex polynomial evaluation) |

|

Geometric Flexibility |

Limited (straight lines only) |

Moderate (arcs and lines) |

High (freeform and analytical shapes) |

|

Surface Finish |

Poor (visible segment transitions) |

Moderate (smoother arcs) |

Excellent (seamless transitions) |

Table 2: Performance in High-speed Machining

|

Metric |

Linear Interpolation |

Circular Interpolation |

Polynomial Trajectories (NURBS) |

|---|---|---|---|

|

Maximum Feed Rate |

Limited by segment transitions |

Limited by arc curvature |

High (smooth paths allow faster feeds) |

|

Vibration |

High (due to abrupt changes) |

Moderate (smoother arcs) |

Low (continuous motion) |

|

Tool Wear |

High (vibrations and impacts) |

Moderate |

Low (smooth dynamics) |

|

Machining Time |

Longer (frequent decelerations) |

Moderate |

Shorter (optimized feed rates) |

|

Accuracy |

Moderate (chordal errors) |

Moderate |

High (precise curve following) |

Practical Applications of Polynomial Trajectories

Polynomial trajectories are widely used in industries requiring high-precision, high-speed machining. Key applications include:

Aerospace

-

Components: Turbine blades, airframe structures, and engine casings.

-

Requirements: Complex geometries, tight tolerances (e.g., ±10 µm), and lightweight materials (e.g., titanium, composites).

-

Benefits of Polynomial Trajectories: Smooth tool paths reduce vibrations, enabling high-speed machining of thin-walled structures without distortion.

Automotive

-

Components: Engine blocks, transmission parts, and molds for body panels.

-

Requirements: High MRR, excellent surface finish, and repeatability.

-

Benefits: NURBS-based paths optimize feed rates, reducing cycle times and improving mold quality.

Mold and Die Making

-

Components: Injection molds, stamping dies, and forging dies.

-

Requirements: Intricate contours, mirror-like finishes, and durability.

-

Benefits: Polynomial trajectories enable precise machining of freeform surfaces, minimizing manual polishing.

Medical Devices

-

Components: Orthopedic implants, surgical tools, and dental restorations.

-

Requirements: Biocompatible materials, ultra-high precision, and smooth surfaces.

-

Benefits: Smooth tool paths ensure biocompatibility by eliminating surface defects.

Challenges and Limitations

Despite their advantages, polynomial trajectories in high-performance NC systems face several challenges:

-

Computational Complexity: Evaluating NURBS curves in real-time requires significant processing power, necessitating advanced controllers.

-

Data Compatibility: Some legacy NC systems do not support polynomial trajectories, requiring upgrades or post-processing of G-code.

-

Tool Path Optimization: Generating optimal polynomial paths requires sophisticated CAM software and skilled operators.

-

Error Sensitivity: Small errors in control points or weights can lead to significant deviations in the tool path.

Future Trends in Polynomial-based NC Systems

The future of high-performance NC for HSM lies in integrating polynomial trajectories with emerging technologies:

-

Artificial Intelligence: AI-driven algorithms for real-time path optimization and adaptive control.

-

Digital Twins: Virtual models of the machining process to simulate and optimize polynomial trajectories before execution.

-

Additive-Hybrid Manufacturing: Combining HSM with additive processes, using polynomial trajectories to ensure seamless transitions between subtractive and additive steps.

-

High-bandwidth Connectivity: 5G and edge computing for faster data transfer and real-time control in smart factories.

Conclusion

High-performance numerical control systems leveraging polynomial trajectories have transformed high-speed machining by enabling smoother, faster, and more precise tool paths. By replacing traditional linear and circular interpolation with spline-based methods like NURBS, these systems achieve superior surface quality, reduced tool wear, and shorter machining times. The integration of advanced control algorithms, high-performance hardware, and real-time feedback systems further enhances their capabilities. While challenges such as computational complexity and compatibility remain, ongoing advancements in AI, digital twins, and connectivity promise to unlock new possibilities. The tables provided highlight the clear advantages of polynomial trajectories over traditional methods, making them a cornerstone of modern HSM across industries like aerospace, automotive, and medical manufacturing.

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. 3, 4 and 5-axis rapid precision CNC machining services including milling, turning to customer specifications,Capable of metal & plastic machined parts with +/-0.005 mm tolerance.Secondary services include CNC and conventional grinding, drilling,die casting,sheet metal and stamping.Providing prototypes, full production runs, technical support and full inspection.Serves the automotive, aerospace, mold&fixture,led lighting,medical,bicycle, and consumer electronics industries. On-time delivery.Tell us a little about your project's budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material