Batch 3D printing helps upgrade traditional industries

It can repair human tissues and realize product manufacturing,Nowadays, 3D printing technology is integrating into traditional manufacturing and realizing industrial transformation at an unprecedented rate of development. In the first batch of participating projects disclosed by Ji Hua Laboratory before, 3D printing technology represents cutting-edge technology and shows the world its infinite possibilities. The reporter learned that 3D printing technology is a strategic emerging industry, and Foshan's smart equipment manufacturing industry, which focuses on 3D printing, is growing rapidly.

Nowadays, a number of professional 3D printing public technical service platforms, incubators, research centers, and 3D printing companies are emerging in Foshan, and the understanding of 3D printing has moved from the conceptual stage to the application stage. When 3D printing technology is more and more widely used in all walks of life, how will the future rely on "3D printing +" to redefine "Made in Foshan"?

Frontier: 3D printing to repair human tissues

Nowadays, it is not surprising that 3D printing technology has "appeared" in leading scientific research fields. At present, among the first 11 participating projects of Jihua Lab, only 3D printing-related technology projects occupy three seats, allowing the outside world to see the frontiers and hotspots in the field of 3D printing.

Taking the "High-precision Medical Implantable Tissue Patch 3D Printing Equipment and Key Technologies for Manufacturing" project hosted by Professor Wang Han of Guangdong University of Technology, the implantable tissue patch developed by this project can realize the safety and rapidity of human soft tissues. Repair, it is possible to leverage the development of the domestic market of 100 billion yuan. The domestic market is currently mainly occupied by European and American manufacturers, and the price of each piece is as high as 20,000 yuan. According to Wang Han’s analysis, only taking hernia repair patches as an example, the market is still increasing at a rate of 20%, and the demand for independent research and development in China is very urgent.

"However, there are still certain problems in international technology, which may produce residual organic matter, uncontrollable structure, and poor mechanical properties." Wang Han revealed that the process he presided over the project is relatively new globally. Solvents are needed, the microstructure can be orderly and controllable, and the mechanical properties are superior. Relying on the State Key Laboratory and Provincial Key Laboratory of Guangzhou University of Technology, the project will not only innovate manufacturing equipment and manufacturing processes, break the situation of dependence on imports in this field, but also lead the direction of high-end industrial applications in the next 30 years and further promote "Leapfrogging" development of national high-end medical consumables. In order to achieve these goals, the project needs to establish a cutting-edge academic investment platform and a top technology research and development platform.

The reporter learned that the project has already been integrated with Foshan's local medical equipment and pharmaceutical technology companies for industrial applications to support local companies' entry into the high-end medical consumables market.

Status: 3D printing is going towards application

3D printing technology is a strategic emerging industry. Foshan's smart equipment manufacturing industry, which focuses on 3D printing, is growing rapidly. A number of professional 3D printing public technology service platforms, incubators, research centers, and 3D printing companies have emerged in Foshan. The understanding of 3D printing has moved from the conceptual stage to the application stage.

Demand: reduce the cost of "molding"

3D printing is a new thing from the past, and now it is becoming more and more popular and common in some industries. The reporter learned that the demand for 3D printing technology and products from some industrial services, education, manufacturing, medical and other companies is showing a rising trend.

In some manufacturing industries, 3D printing is widely used in the research and development stage of product parts, and in the industrial design industry, which is well-developed in Foshan’s industrial service industry, 3D printing technology is now also widely used and brings substance to enterprises. The benefits of sex.

"Guarantee time, accuracy and cost savings are the two major benefits of companies using 3D printing technology." Now that 3D printing technology products are mature and widely used, industrial design companies can quickly "print" small product models by using this technology. come out. “In the past, we had to open the mold for the actualization of the product we designed, and the cost was very high; now, the product model can be quickly formed through the 3D printing machine, which is very convenient and effectively reduces the cost.” From the perspective of only a single product, the preliminary finished product is expected to be saved. 50% of the cost.

Link to this article: Batch 3D printing helps upgrade traditional industries

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

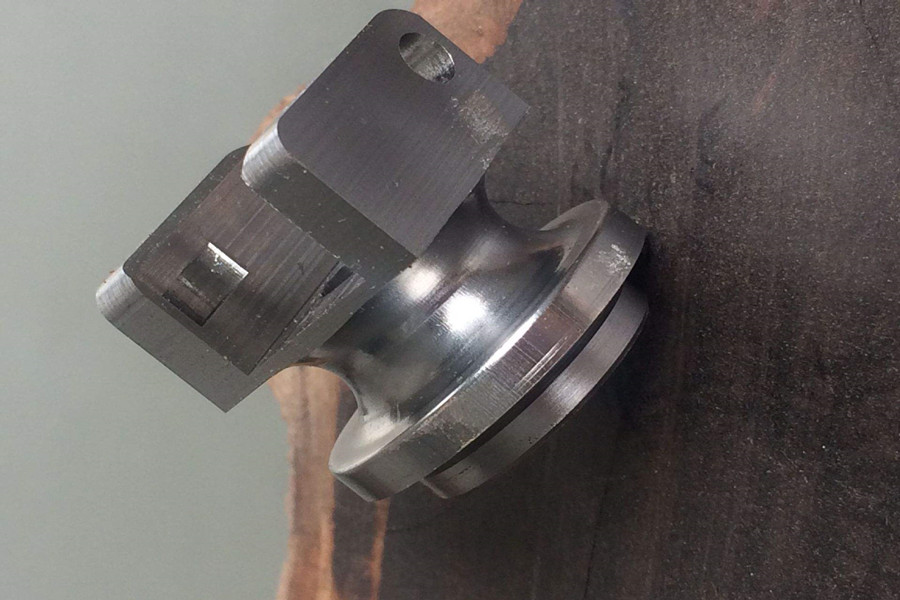

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material