CHINA INVESTMENT CASTING SERVICES | LOST WAX INVESTMENT CASTING

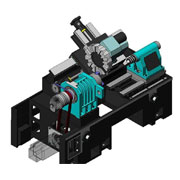

Excellent CNC machining capabilities make our investment casting more advantageous

|

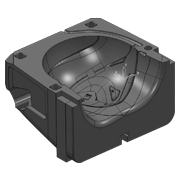

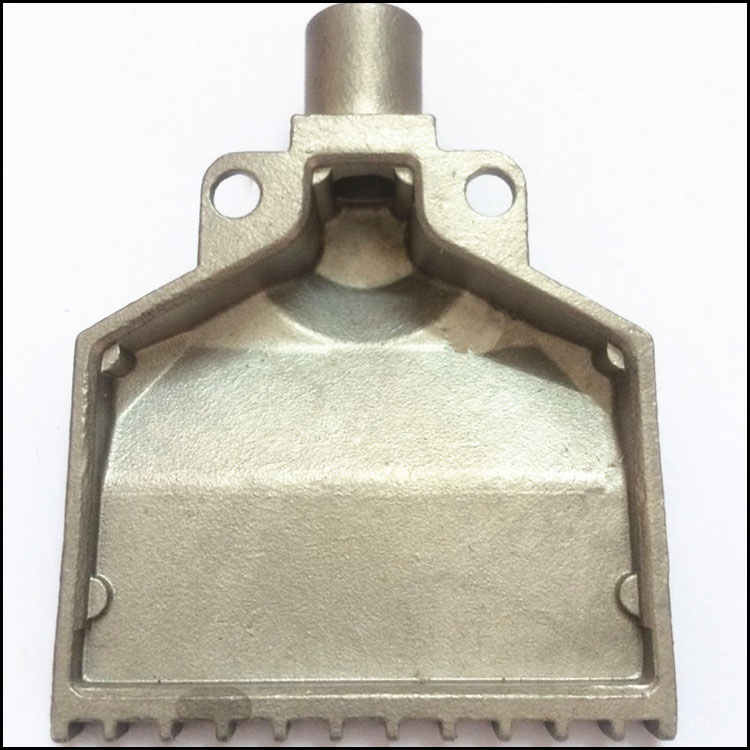

What is Investment casting? It also known as lost wax casting, includes processes such as pressing wax, repairing wax, assembling trees, dipping slurry, melting wax, casting molten metal, and post-processing. Lost wax casting is to use wax to make a wax mold of the part to be cast, and then coat the wax mold with mud, which is a mud mold. After the clay mold is dried, put it in hot water to melt the internal wax mold. Take out the clay mold from the melted wax mold and fire it into a pottery mold. Once roasted. Generally, a pouring port is left when making a mud mold, and then molten metal is poured from the pouring port. After cooling, the required parts are made. PTJ Shop Is ISO 9001:2015 and AS 9100 Rev. C certified custom manufacturer offering Investment castings. Capable of handling parts weighing from 1 oz. to 10 lbs. Available in short to medium-sized runs with up to 100,000 production pieces. Also capable of molding, CNC machining, stamping, tooling, and finishing.Industries served include industrial lighting, automotive, medical, agriculture, off-road vehicles, telecommunications, electronics, and meter components industries. PTJ Group entered the investment casting industry in 2015 and obtained orders from 12 Chinese listed companies.PTJ produce precision tolerances lost wax investment castings from both ferrous and non-ferrous metals(aluminum investment casting/stainless steel investment casting/titanium investment casting/brass investment casting/Sand casting/Carbon & low alloy casting etc.,) in the required specifications for medical, aerospace, and other critical industry applications at our foundry. |

|

|

|

|

|

|

|

|

Contact our investment casting services enginers today to discuss the specifics of your complex parts. |

We are proud to produce complex investment cast parts with superior surface finishes in the industries fastest lead-times for the following markets:

- ▶ Aerospace

- ▶ Defense

- ▶ Medical

- ▶ Electronics

- ▶ Automotive

- ▶ Oil and Gas

- ▶ Agriculture

- ▶ Commercial

|

|

|

|

|

|

|

High Accuracy |

Quick Quote& Service |

Fast Delivery |

Custom Finishes |

Precision Machines |

Addition Services |

|

|

Investment Casting Process Steps at China Casting Company |

The following steps are what we follow to produce parts with complex geometries and intricate details.

-

▶ Create wax pattern: A pattern that replicates the finished part geometry is made using one of two primary methods:

Build a wax injection die

3D print pattern

If a wax injection die will be used, the first step involves designing and building a metal die from Aluminum. This die creates a wax replica of the desired part by injecting melted wax under high pressure into the cavity. The die can be made as a simple one cavity manual tool or a complex multi-cavity automatic tool depending on volume requirements.

If a 3D printed pattern will be used, a CAD model which contains the part geometry is sent to a printer and the part is printed

- ▶ Wax Assembly: Next, the wax patterns are assembled onto runners and into a finished tree which is ready to be dipped.

-

▶ Slurry Coating: The assembly is then dipped into a high-grade ceramic slurry to build a ceramic shell around the wax tree.

- ▶ Stuccoing: After the slurry coating is done, particles of sand are dropped onto the surface of the wet tree assembly. This helps to thicken and strengthen the layer of coating on the wax assembly surface.

- ▶ Repeat Steps 5 and 6: Repeat steps 5 and 6 until the assembly achieves the desired shell thickness. The assembly is then allowed to set and dry.

- ▶ Dewaxing: The wax inside the newly built shell is now removed. Dewaxing is done using a steam-dewaxing autoclave or flash fire furnace.

-

▶ Casting: Now the desired molten metal is poured into the pre-heated mold cavity.

- ▶ Cooling: The mold then sits to allow the molten metal to cool and solidify which then becomes the final casting. (complete equipment list)

- ▶ Shell Removal: The shell material is then removed through processes hammer knockout, vibration, and steel grit blasting.

- ▶ Cut Off: The finished parts are then cut free from the gating and runner system.

- ▶ Finishing: Various finishing techniques are then employed including grinding, sand blasting and coating to achieve the final surface needed.

- ▶ Testing: Once the finishing operations are done, the parts are inspected for surface and sub-surface defects. Visual and fluorescent penetrant inspection is done for surfaces and X-ray is employed for sub-surface defect identification.

|

|

Our Investment Casting Facility And Castings Case |

|

|

|

|

|

Automatic shell making assembly line |

Automatic wax injection machine |

Brinell Rockwell hardness tester |

Metallographic analyzer |

|

|

|

|

|

Casting workshop |

Medium temperature wax workshop |

Steam dewaxing kettle |

Tensile testing machine |

View more machining technology on our Gallery Page

PTJ has been serving customers all over the world since 2007. We keep sharping our skills and improve our equipment to make sure our customers are satisfied. We have so many loyal customers who have worked with us for more than 10 Years. Let’s view the other machining technology and learn more calture about PTJ Hardware.

|

|

|

|

|

| View Detail >> | 1 | View Detail >> | 1 | View Detail >> |

|

|

|

|

|

|

|

|

|

|

|

| View Detail >> |

|

View Detail >> |

|

View Detail >> |