What are the well-known car companies doing with 3D printing technology?

Using 3D printing technology can effectively improve automobile production efficiency, reduce production costs, and make the appearance more personalized. Over the years, Qiuping Model has closely participated in the production of many exhibition cars and accessories under many auto brands, and has produced test models and functional prototypes as a means of design verification and evaluation before new cars are put into production.

1. Styling review

The creative review of automobile styling is an important node in automobile design, which determines the process of automobile styling and the process of design iteration. Due to the rapid prototyping characteristics of 3D printing, R&D personnel can use 3D printing technology to produce conceptual models within hours or days.

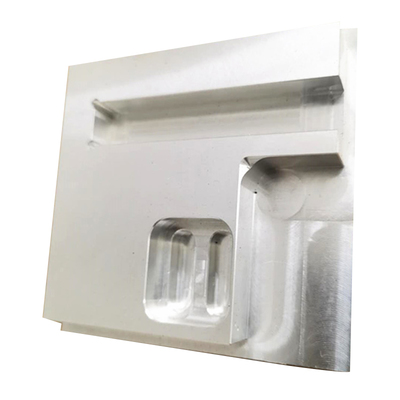

2. Manual samples for design verification and performance testing

In vehicle product development, it is usually necessary to verify the product design reliability (installation structure, part matching, structural strength, etc.). At the same time, in order to compensate for the design risk brought by the vehicle test in the middle and late stages of the vehicle development, it is necessary to perform the design in the early stage. Prototype verification. At this time, SLA process can be used to make prototype parts for functional and assembly inspection.

3. Complicated parts

During the development process, when the structural design is complicated and cannot be manufactured using traditional manufacturing processes, or the traditional manufacturing cost is very high, such complex structural parts can be printed by 3D, which can be used in a short time and at a lower cost. , To verify the designer’s design ideas. For example: There are many front grille and curved surface structures in a car. This kind of fully meshed complex modeling is very difficult to process on traditional machine tools. By 3D printing these complex partial parts and then inlaid into the vehicle model, it can be To achieve the desired effect.

4. Multi-material composite parts

In the process of vehicle product development, it is inevitable to encounter a variety of different material composites, such as: rubber and plastic, composites of different color materials, such as: taillight outer lens; transparent and opaque materials composite, such as: headlight decoration Circle lights. Compared with traditional two-shot injection molding, two-color injection molding and other processes, 3D printing has obvious advantages in mold cost, part joint structure, part strength and reliability.

5. Lightweight structural parts

Automotive lightweighting has taken up an increasingly important position in product development. With 3D printing technology, it is possible to use plastics and even metals to manufacture hollow lightweight structural parts, such as the research and development of lightweight 3D printed car seats to reduce weight. 72%.

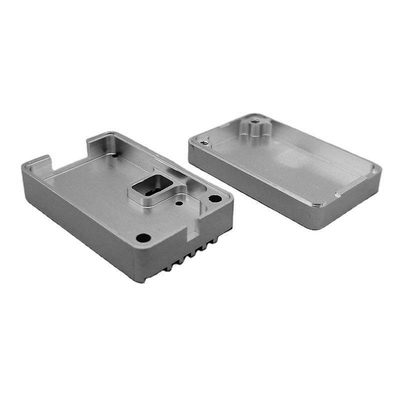

6. Customized special tooling

In addition to auto parts, special assembly parts, measuring tools, and inspection fixtures on the production line are also very suitable for using 3D printing technology.

7. After-sales personalized customization

In the personalized car body outer cover parts, car interior and exterior trim (bumper, instrument panel, car central control, spoiler, etc.) parts are more and more attractive to young customers, 3D printing is most suitable for personalized customization.

Conclusion: In the automotive industry, 3D printing has great advantages in terms of overall product strength, accuracy, and response speed. The use of multiple 3D printing equipment linkages can also greatly reduce product development costs. Intensified market competition and shortened product life cycles, more and more companies are aware of the importance of R&D speed and cost control, making the use and application of 3D printers in the industrial field more and more popular.

Link to this article: What are the well-known car companies doing with 3D printing technology?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material