See how leading bearing manufacturers play with 3D printing technology?

Bowman International, a leading bearing designer and manufacturer, in addition to producing conventional bearing products, Bowman also produces customized bearings. In 2016, Bowman established a special additive manufacturing production department-Bowman Additive Production. The business of this department is to provide industrial bearing users with customized bearing design, prototyping, testing, inspection, production and other services.

The application of 3D printing technology has enabled Bowan to enhance the ability of small batch bearings to produce quickly, and has brought more room for Bowan to optimize the performance and life of some of its bearing products.

Small batch production and implementation of complex designs

So far, Bowman Additive Production is equipped with two additive manufacturing equipment, one is EOS's selective laser sintering equipment, and the other is HP's multi-jet fusion equipment (MJF). Bowman uses nylon 11 as the printing material.

Bowman's first product developed using 3D printing technology is a plastic bearing cage. The application of 3D printing technology enables Bowman to produce plastic bearing cages without the need for injection molds. This not only enables Bowman to respond quickly to product design modifications, but also enhances its competitiveness in the rapid production of small and medium batches of customized bearings.

With the help of 3D printing technology, Bowman has optimized the cage design. Many complex structures are integrated in the cage. The 3D printing equipment can realize the production of this complex design in an economical way.

According to the understanding of 3D Science Valley, the main function of the cage is to keep the rolling elements at an appropriate distance between each other, reduce the friction torque of the bearing and the heat generated by friction, and make the rolling elements evenly distributed in the entire bearing to optimize the load. Distribute and reduce noise. Therefore, the design and material of the cage have a major impact on the applicability of rolling bearings in specific applications.

When designing the 3D printed cage, Bowman adopted an interlocking structure, with rolling elements fixing each part of the cage together. The advantage of this design is that there is more space around the cage circumference, so compared with similar products on the market, this cage product can add 2-4 rolling elements. This means that the bearing load can be distributed over a larger number of rolling elements.

Bowman said that the 3D printed bearing cage with this design increases the load-carrying capacity of the split bearing by 70% and extends its working life to 500%. Bowman can increase bearing load capacity and life without changing the design of other components in the bearing.

Link to this article: See how leading bearing manufacturers play with 3D printing technology?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

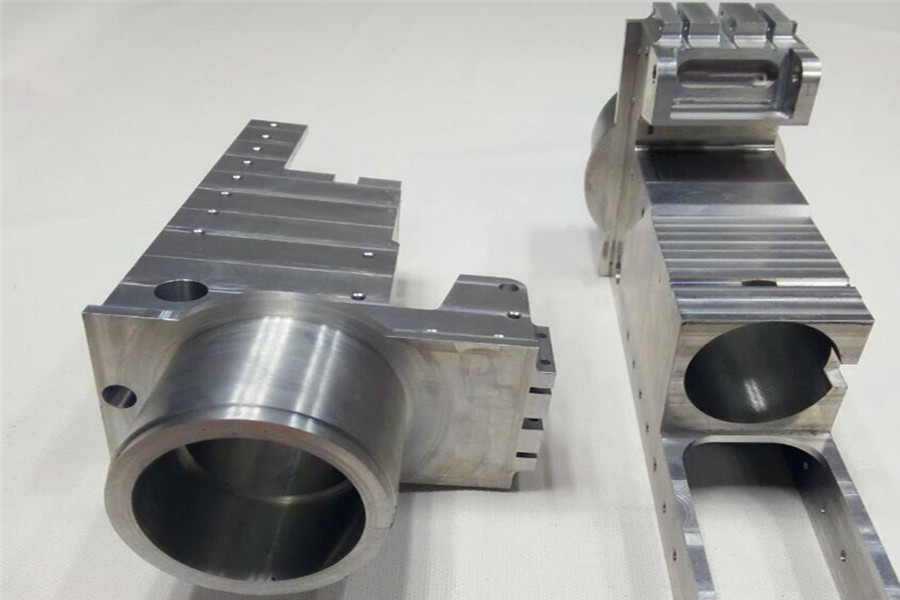

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material