Preparation of large-size alumina grinding disc

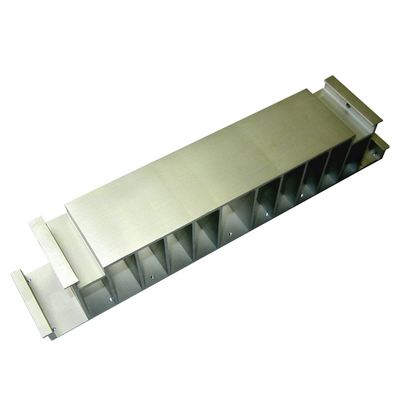

Large-size structural ceramic parts have a wide range of applications in semiconductor manufacturing equipment and other fields, but the molding of large-size ceramic parts is extremely challenging. Recently, a scientific research team led by researcher Wang Shiwei from the Shanghai Institute of Ceramics, Chinese Academy of Sciences cooperated with the company to establish a spontaneous gelation system based on a polyfunctional copolymer of isobutylene and maleic anhydride (PIBM) with independent intellectual property rights. Breakthrough the key bottleneck problems such as deformation and cracking of large-size wet ceramic blanks during the drying process, and successfully prepared large-size high-purity alumina ceramic grinding discs with a diameter of 360mm to 600mm.

Compared with classic cold isostatic pressing and grouting, gelcasting (or gel injection molding) has outstanding advantages: the microstructure of the green body is uniform, and the reliability of the ceramic parts is fundamentally guaranteed; The billet has high strength and density and is convenient for handling, which can effectively reduce the risk of sintering shrinkage and cracking; near-net-size molding can greatly reduce the cost of machining. In addition, the injection molding process equipment is simple, which can effectively reduce the production input cost, and has huge application potential in the preparation of large-size ceramic parts. However, the gel system based on free radical polymerization has problems such as toxic monomers, oxygen inhibition, many types of additives, and large additions; in addition, the drying mechanism of ceramic gels has not been clearly explained, which seriously hinders the use of injection molding technology. Widely used in the preparation and industrialization of large-scale structural ceramic parts.

Wang Shiwei's research team has been exploring and researching new gel curing systems since 2003. First developed a water-soluble epoxy resin-polyamine gel system based on nucleophilic addition polymerization (J. Am. Ceram. Soc., 2008), which has been successfully applied to dense Al2O3, AlN and SiC, translucent Al2O3, The molding of advanced ceramics such as transparent Y2O3, YAG, AlON, and foam Al2O3. In 2011, the team discovered the phenomenon of spontaneous solidification in the study of preparing Al2O3 ceramic slurry using PIBM (J. Mater. Res., 2013). Subsequently, the focus was on the universality of the PIBM spontaneous solidification system, the drying mechanism of the ceramic gel, the internal stress of the pre-sintering process, and the development of large-size ceramic parts preparation technology.

Compared with other gel systems, the PIBM spontaneous coagulation system has significant advantages such as fewer types of additives, less addition, and simple operation. Under normal temperature and atmospheric environment, only one kind of organic copolymer can be used to realize the spontaneous solidification molding of Al2O3, and the prepared Al2O3 ceramic wet body has good flexibility. At the same time, the solidification system has a wide range of universality and has been successfully applied to the preparation of porous, dense and transparent ceramics in a variety of oxide and non-oxide systems. By comparing the drying process of the epoxy resin-polyamine gel system and the PIBM spontaneous solidification system, the team found that the density of the organic network significantly affects the drying behavior of the ceramic wet body. The organic network formed by the PIBM spontaneous solidification system is conducive to water transport, drying stress is easier to release, and the body does not deform after drying; while the organic network formed by the epoxy resin-polyamine gel system hinders water transport, and the drying stress is large. The green body is easy to dry and deform.

In the past five years, the research team has published more than 20 research papers related to PIBM's spontaneous solidification molding in internationally renowned journals on materials and ceramics, and its core technology has been authorized for 6 Chinese invention patents. Since the report, the PIBM spontaneous solidification molding system has attracted widespread attention from domestic and foreign counterparts. For example, domestic Tsinghua University, Wuhan University of Science and Technology, Sichuan University, University of Electronic Science and Technology of China, Beijing Institute of Aerospace Materials and Technology, Beijing University of Aeronautics and Astronautics, Chinese Academy of Engineering Physics, and foreign U.S. Army laboratories, U.S. Alfred University, Iranian Institute Nearly 20 research institutions and research groups such as Latse University of Technology have adopted this solidification system to carry out research on injection molding of a variety of advanced ceramics.

At the same time, the research team has been committed to the promotion and application of new molding technology. In July 2017, with the new PIBM spontaneous solidification system as the core technology, the Shanghai Institute of Ceramics and Jiangxi Pingxiang Enterprise jointly established Jiangxi Zhongkete Ceramic New Material Co., Ltd. to carry out the industrialization of large-size and high-purity alumina ceramic parts . At present, the company has built a pilot production line, has mastered the key technologies of drying, debonding and high-temperature sintering of spontaneously solidified large-size alumina grinding discs, and has prepared high-purity alumina grinding discs of various specifications with a diameter of 360mm-600mm. It has laid a solid foundation for large-scale production.

The PIBM spontaneous solidification molding technology is applied to the preparation of large-size advanced ceramic materials. It has significant originality and advancement. It will provide a new low-cost manufacturing method for large-size ceramic parts required for the localization of semiconductor manufacturing equipment in China. The research was supported by the Pinghu New Material Center Project of the Chinese Academy of Sciences, the Shanghai Excellent Technology Leader Project, the National Natural Science Foundation of China, and the key research and development plan of the Ministry of Science and Technology.

Link to this article: Preparation of large-size alumina grinding disc

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material