What are the technological characteristics of screen cutting

The laser cutting principle of screen pipe cutting is to cut thousands of gaps in the alloy steel casing according to law. Commonly used gap specifications are: the gap width is 0.153mm, the gap length is 50mm, and the gap section is mainly rectangular and trapezoidal. Laser screen cutting is to irradiate the screen with a focused high-power density laser beam to assist coaxial oxygen blowing. The energy of the laser beam is absorbed by the material, causing the surface temperature of the material at the point where the laser beam is irradiated to rise sharply. After reaching the ignition temperature of the material, a strong oxidation reaction occurs in contact with oxygen, releasing a lot of heat. Under the combined action of laser beam energy and oxidation reaction heat, when the sleeve moves relative to the laser beam, the tube body will be damaged, and slits can be processed on the tube body.

The screen cutting gravel packing sand control technology is a new technology developed on the basis of the steel wire wound screen gravel packing sand control technology. The principle of screen cutting is to use oil pipes to lower the sand control string composed of sand control screens and sand filling tools to the oil zone, and then use sand pack trucks to fill the sand into the screen casing annulus and the formation near the well. The purpose of the cutting production enterprise is to realize the artificial sand gravel to form sand bridges and prevent fine silt sand in the oil layer.

The center tube of the screen tube uses standard oil and casing, and the center tube uses auger. On the basis of ensuring the total flow area of the tube body, the cross-sectional opening area of the tube body is reduced and the strength of the center tube is maintained.

The formation sand is blocked outside the screen, and the oil, gas or water in the formation passes through the filter section, and then enters the screen through the borehole. Ways to achieve sand control. The screen is suitable for various oil, gas, and water wells such as vertical wells, inclined wells, horizontal wells, etc. for casing completion and open hole completion. It can be used alone as a sand control pipe string, or it can be used in combination with packing. From the inside to the outside, it is composed of a mother pipe, a composite sand control filter sleeve and a stainless steel outer protective sleeve.

The slotted pipe is processed with J55 or N80 petroleum casing body, which has high strength and is not easy to deform. The cutting edge has good verticality, smooth cutting edge, no burrs, and even cutting. The gaps are evenly distributed along the axial direction of the pipe body, no external filter screen is needed, and the construction is convenient. It is an ideal choice for inclined wells and horizontal completion sand control wells. The entire anti-corrosion treatment forms a dense protective layer on each surface of the screen, which improves the anti-corrosion and wear resistance of the screen and can effectively extend its downhole service life.

Compared with the wire-wound screen, the slotted screen has the characteristics of high strength and large inner diameter; the squeeze filling technology greatly increases the amount of sand filling, changing the situation that the amount of sand filling is small in the past, and the formation sand is compared with artificial sand. The sand-gravel mixture reduces the permeability of the sand-gravel layer. Screen cutting manufacturers use the extrusion filling process instead of the cyclic sand filling process, which is beneficial to the sand control effect.

Link to this article: What are the technological characteristics of screen cutting

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

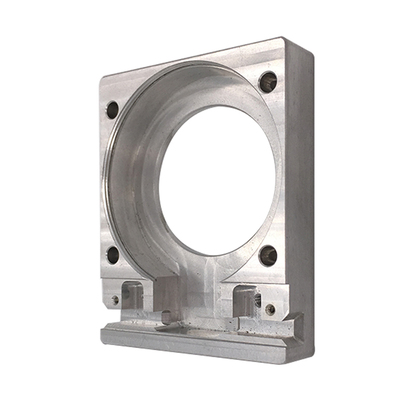

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material