Research and development of 3D printed tissue to repair damaged joints

Biological scientists are developing 3D printed tissues to help treat bone and cartilage damaged in sports injuries in the knees, ankles and elbows. Scientists at Rice University and the University of Maryland have designed a scaffold that can replicate the physical characteristics of osteochondral tissue, which is basically a hard bone under a compressible layer of cartilage, with a smooth surface at the end of the long bone.

These bone injuries, from small cracks to broken fragments, are painful and often hinder an athlete's career. Osteochondrial damage can also cause arthritis and disability.

The gradient nature of cartilage into bone and its porosity make it difficult to reproduce in the laboratory, but Rice University bioengineer and graduate student Sean Bittner used 3D printing technology to create a Implant materials that provide suitable materials.

"Athletes are particularly affected by these injuries, but they may affect everyone," said Bittner, who is also a researcher at the National Science Foundation and the lead author of the paper, which was published in Acta BioMaterialia) on. "I think this will be a powerful tool to help people with common sports injuries."

The key is to mimic the tissue gradually shifting from the cartilage on the surface (cartilage tissue) to the bone (bone) below. The researchers printed a custom polymer blend scaffold for the former, and a ceramic blend embedded in the pores for the latter, which allows the patient’s own cells and blood vessels to penetrate the implant, eventually turning it into natural bone and cartilage. a part of.

"In most cases, the composition of the 3D printed stent is the same for the patient and the patient," Bittner said. "Both contain porosity, so blood vessels can grow from native bone. We don't have to make blood vessels ourselves."

In the future, the project will include how to print an osteochondral implant to make it completely suitable for the patient and allow the porous implant to grow and bond with bone and cartilage.

Other collaborators are from Rice University, the University of Maryland, and Wake Forest School of Medicine. The National Institutes of Health and the Regenerative Medicine Development Organization supported this research.

Link to this article: Research and development of 3D printed tissue to repair damaged joints

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

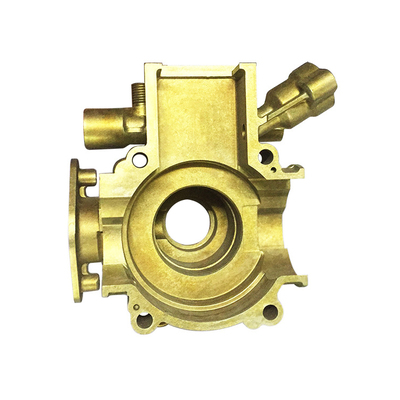

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material