Secret deformation mechanism of nanocrystalline aluminum

Nanocrystalline metals with a grain size of less than 100 nm usually have unique properties, which are better than similar coarse-grained metals. Aluminum (Al) is a metal with a wide range of uses. It is considered an indispensable engineering material due to its high specific strength, light weight and corrosion resistance.

In order to improve its mechanical properties, some researchers have tried to produce Al with nano-scale grain sizes. Reducing the grain size to the nanometer level results in extremely high strength, which may trigger a unique plastic deformation mechanism not observed in coarse-grained materials. However, almost all reports are about ultra-fine crystalline aluminum with a grain size of 100 nm to 1 μm, and there are few reports on the mechanical properties of bulk nanocrystalline Al.

The University of Qatar and the University of Minnesota synthesized bulk nanocrystalline Al by in-situ consolidation in the process of liquid nitrogen and room temperature ball milling. Studies have shown that the tensile properties are caused by the dislocations of the larger nanocrystalline grains and the crystal grains. The partial dislocations of the smaller nanocrystalline grains and the deformation twins controlled by stacking faults are determined.

The researchers analyzed the tensile behavior of nanocrystalline Al and correlated it with the structural characteristics of the nanostructure. Compared with conventional coarse-grained commercial pure aluminum, nanocrystalline aluminum has extremely high tensile strength, strain hardening rate and ductility. The tensile strength of this bulk nanocrystalline Al is at least ten times higher than the strength of common commercial coarse-grained pure aluminum. The average yield strength of the nanocrystalline Al sample is as high as 375 MPa, the average tensile strength is 410 MPa, and the total elongation is Is 10%. Achieved ultra-high yield and tensile strength, while having good ductility and strain hardening properties.

The study found that the average elongation and total elongation of the nanocrystalline Al samples were 4.5% and 10%, respectively. The nanocrystalline Al after yielding shows a higher strain hardening index of 0.132 than that of the coarse-grained Al. Using HR-TEM to observe relatively small nanocrystal grains (10-25 nm), it is found that there are deformation twins in the nanocrystals. The partial dislocations and stacking faults emitted from the grain boundaries of the {111} slip plane can promote the generation of these deformation twins. The extremely high strength of nanocrystalline Al is attributed to the small grain size and deformation twins. The dislocation density in the large nano-particles formed during the tensile test is high, while the deformation twins in the small nano-crystalline grains are high, which may be the main reason for the high n value and good ductility.

In general, in this paper, nanocrystalline pure aluminum with high stacking fault energy was prepared, and TEM and mechanical properties were analyzed respectively. The focus was on the tensile strength of bulk nanocrystalline Al by grain size and different deformation mechanisms. Performance impact. The effects of deformation twins and other plastic deformation mechanisms on the tensile properties of nanocrystalline Al are described. This study provides a reference for the subsequent strengthening mechanism of aluminum alloy.

Link to this article: Secret deformation mechanism of nanocrystalline aluminum

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

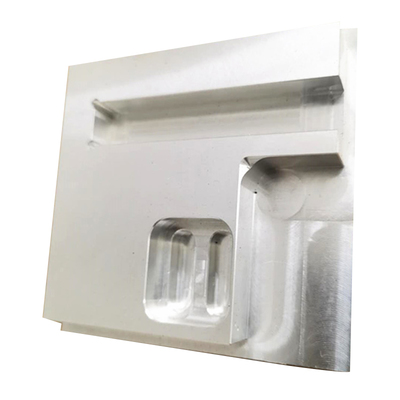

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material