Highly functional graphene 3D printing material was born

Recently, a research team from Zhejiang University used the solvation effect of glycerol molecules on graphene oxide to design a graphene oxide/glycerin 3D printing ink. This research has opened up the scope of new three-dimensional graphene frame materials and laid the foundation for the application of graphene materials in the fields of energy storage, composite materials, catalysis and other fields.

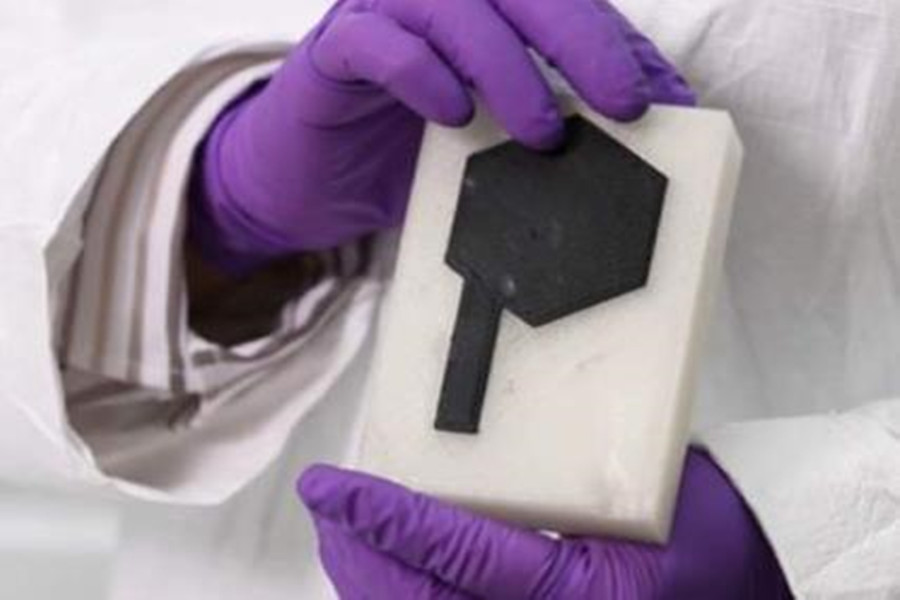

The research team designed a high-concentration homogeneous graphene oxide/glycerin dispersion as a 3D printing ink, and explored the influence of graphene oxide concentration on the rheological behavior of the dispersion. They used ink direct writing technology to prepare graphene microlattice materials. The obtained graphene microlattice material exhibits the characteristics of high density, high strength, high compressibility and high conductivity, and has good application prospects.

Solvated graphene-based materials are an important topic in the field of preparation of graphene macroscopic assemblies. Using the liquid crystal behavior and colloidal properties of graphene oxide aqueous dispersions, scientists have previously developed a series of routes to prepare graphene fibers, membranes, aerogels and other macroscopic assemblies using graphene oxide as a precursor. However, these routes present new challenges when adapting to 3D printing technology. 3D printing technology has stringent rheological requirements for printing inks such as high viscosity, high modulus, and rapid shear thinning, which are difficult to achieve with traditional graphene oxide dispersions.

The development of 3D printing technology is inseparable from the development of its printing materials. At present, the more mature 3D printing technologies include SLS, SLA, FDM, etc. The printing materials corresponding to different printing technologies are also different. For example, the commonly used printing materials for SLS are Metal powder, while SLA usually uses photosensitive resin, FDM uses a wide range of materials, such as ABS plastic, PLA plastic and so on.

Graphene is called black gold, the king of new materials, and scientists even predict that graphene will "completely change the 21st century." It is currently the thinnest material known, only one carbon atom thick, and it is also the strongest material, about 200 times stronger than structural steel. Graphene’s electrical conductivity is better than copper, and its thermal conductivity is better than all other materials. Graphene is almost completely transparent, but its structure is so tight that even the smallest atomic helium cannot pass through it. As a new type of nanomaterial with the thinnest, strongest, and strongest electrical and thermal conductivity discovered so far, graphene is very likely to set off a disruptive new technology and new industrial revolution sweeping the world.

As early as 2016, HCS, a well-known graphene company and a wholly-owned subsidiary of HGI, a London-listed company, announced that it would cooperate with thermoplastic 3D printing wire manufacturers Filamentprint and Fullerex to promote and sell graphene-enhanced polylactic acid (PLA) wires. For 3D printing applications.

It is reported that this graphene-enhanced PLA wire is available in two specifications of 1.75 mm and 2.85 mm wire diameter. The wire has excellent first-layer adhesion and Z-axis strength retention, faster processing speed, and improved Strength and performance, excellent surface effect and improved dimensional accuracy and other characteristics.

It is not difficult to imagine that if graphene can be successfully used as a 3D printing material, the performance of the parts that can be constructed by 3D printers in terms of strength, lightness, flexibility and conductivity will be greatly improved.

Link to this article: Highly functional graphene 3D printing material was born

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

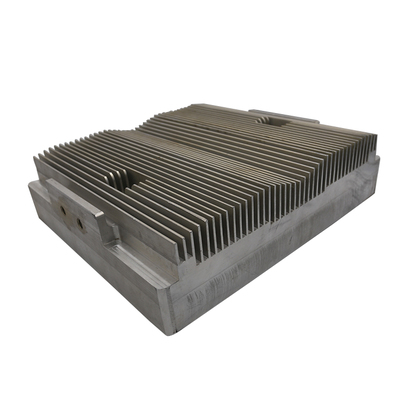

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

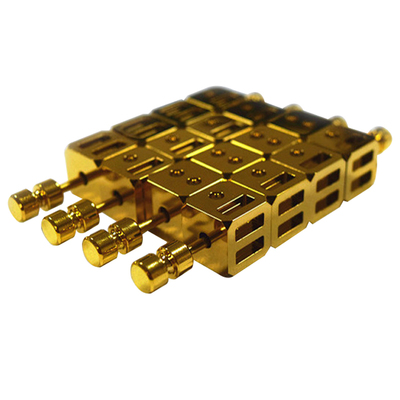

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material