Ultra-light, pressure-resistant tensile metamaterials, deformability increased by 25 times

The catastrophic collapse of materials and structures is an inevitable result of a chain reaction of local restricted damage, from solid ceramics that produce small cracks to metal space trusses, which quickly disintegrate after small cracks are formed.

In a study published this week in Advanced Materials, engineers at the University of California, Irvine and Georgia Institute of Technology described the creation of new mechanical metamaterials that can non-localize deformation to prevent failure. They did this by using Tensegrity (a century-old design principle) in which isolated rigid rods were integrated into a flexible rope net to produce a very lightweight, self-tensioning truss structure.

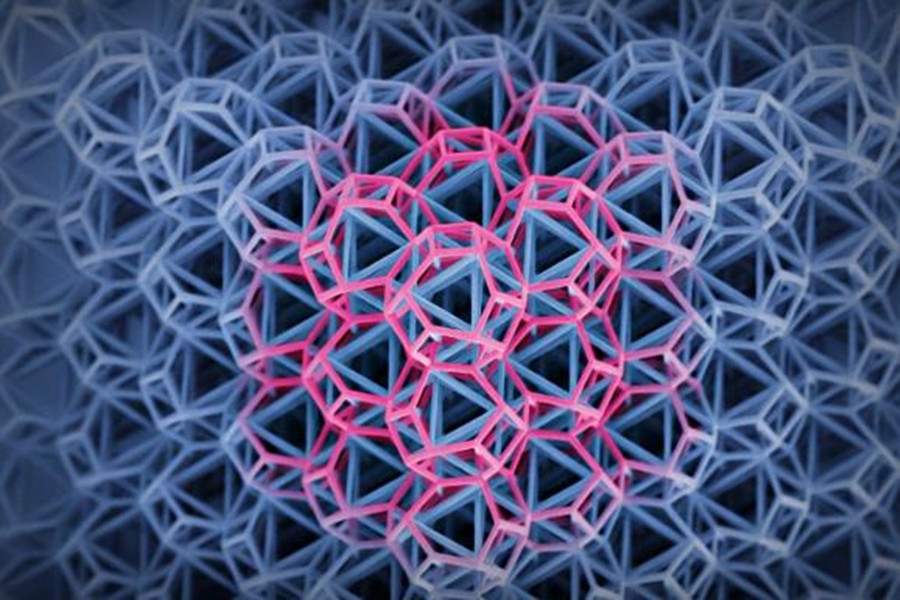

The new tension metamaterial developed by researchers at UCI and Georgia Institute of Technology uses isolated compression ring elements that are only connected by a continuous network of tensile members (highlighted in magenta).

The team started with a diameter of 950 nanometers and used advanced direct laser writing technology to generate basic cells with sizes between 10 and 20 microns. They are assembled into eight-cell super cells, which can be assembled with other cells to form a continuous structure. Then, the researchers conducted computational modeling and laboratory experiments, and observed that these structures exhibited unique uniform deformation behavior without local overstress or underuse.

The research team showed that the deformability of the new metamaterial is increased by 25 times, and the energy absorption rate is several orders of magnitude higher than the latest lattice arrangement.

Lorenzo Valdevit, senior co-author of Uren, a professor of materials science and engineering at UCI, said that tension structures have been studied for decades, especially in the context of architectural design. Tension structures have recently been discovered in many biological systems. A few years ago, our co-author, Julian Rimoli of Georgia Institute of Technology, conceptualized only proper periodic tension lattices in theory, but through this project, we realized these metamaterials The first physical realization and performance demonstration of.

Compared with the other two latest nanoscale structures, the tension lattice created by UCI and Georgia Institute of Technology researchers (center) showed a 25-fold increase in deformability and an order of magnitude increase in energy absorption.

When developing a structural configuration for a planetary lander, the Georgia Institute of Technology research team discovered that a tension-based vehicle can withstand severe deformation or buckling of its individual components without collapsing, which has never been found in other structures. .

Georgia Institute of Technology Aeronautical Engineering Professor Rimoli explained: This gave us the idea of creating metamaterials using the same principles, which led us to discover the first ever 3D tension metamaterial.

This is made possible by novel additive manufacturing techniques. The extremely light and strong rigid traditional structures based on micron-sized trusses and lattices have attracted a lot of interest from engineers because they can replace heavier objects in airplanes, wind turbine blades, and many other objects. The potential of solid matter. Although these advanced materials have many desirable qualities, they can, like any load-bearing structure, still suffer catastrophic damage under overload conditions.

UCI mechanical and aerospace engineering research scientist lead author Jens Bauer explained that in familiar nanostructured materials, failure usually begins with highly localized deformation. Shear bands, surface cracks and buckling of walls and pillars in one area can cause a chain reaction, which leads to the collapse of the entire structure.

He explained that when the compression member buckled, the lattice of the truss began to collapse because the truss under tension could not bear it. Usually, these parts are interconnected at common nodes, which means that in the event of a failure, the damage will quickly spread throughout the structure.

In contrast, the compression members of the tension structure form a closed loop that is isolated from each other and connected only by the tension member. Therefore, the instability of compression members can only be propagated through the tensile load path, and if they do not break, they will not experience instability. Push and pull the tension system downwards, and the entire structure is evenly compressed to prevent local damage, otherwise it will cause catastrophic damage.

According to Valdevit, who is also a professor of mechanical and aeronautical engineering at UCI, tensile metamaterials show unprecedented resistance to destruction, extremely high energy absorption, deformability and strength, and outperform all other types. The latest light construction.

This research provides an important foundation for the design of advanced engineering systems, from reusable impact protection systems to adaptive load-bearing structures.

Link to this article:Ultra-light, pressure-resistant tensile metamaterials, deformability increased by 25 times

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material