Add AI and machine vision to 3D printing

A bioengineer from the Queensland University of Technology (QUT) Bioengineering Transformation Center for Bionics, and Professor Paul Dalton of the University of Oregon, conducted an interdisciplinary study that outlined the integration of artificial intelligence (AI) and machine vision into 3D printers to make customized medical treatments Implants.

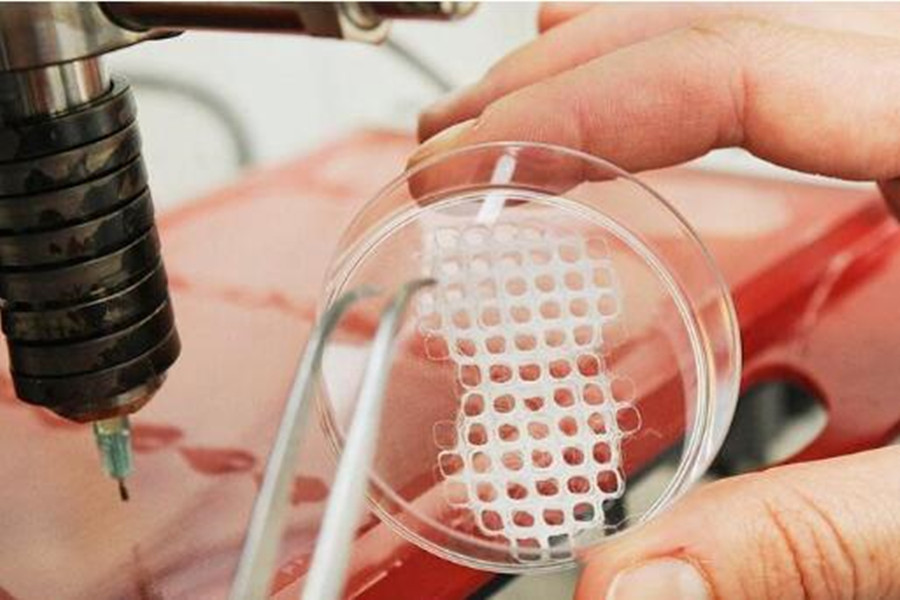

Providing this “eye and brain” for its Melting Electro-Writing (MEW) 3D printer can basically see and learn the will, so that customized tissue implants can meet the needs of individual patients. The integration of artificial intelligence and machine learning will also contribute to the system's ability to print heart valves and soft robots.

Implants and devices produced by traditional manufacturing methods usually adopt standard sizes, before 3D printing changed the advanced manufacturing of implants and medical devices.

The team is working hard to bring the benefits of 3D printing to a series of biodegradable medical device designs that are said to have never been printed before, such as heart valves, bone scaffolds, membranes for dental tissue engineering, and for minimal use Soft robotic invasive surgery.

Commercially available 3D printers usually only provide high-speed, high-precision or medical-grade biological materials, and rarely provide these three materials at the same time. This limits their applicability as medical device manufacturing platforms, such as biodegradable scaffolds for tissue engineering. The addition of AI and machine vision to 3D printing has changed this paradigm.

MEW is a high-resolution additive manufacturing technology that can accurately write small diameter fibers directly into the collector. The difference between MEW and other 3D printing technologies based on melt extrusion is the stable melt jet with electrohydrodynamic dynamics, which can achieve fiber micro-scale resolution of 0.8 to 50 microns.

Compared with other 3D printing technologies, the nozzle of the printer is deliberately raised above the collector to provide an ideal visual access point for process monitoring during the printing process.

To provide MEW printers with "eyes and brains that have been missing so far," the team is pairing its MEW 3D printer with machine vision and machine learning systems.

The machine vision system comprehensively images the flight path of the extruded fiber to correct errors in real time, while the machine learning system uses this information to predict the fiber diameter of the stent and manufacture a more accurate final product.

The processing of high-performance materials such as medical-grade biomaterials for implants is very complex and requires fine-tuning of all process parameters. This is why we closely monitor the 3D printing process, using artificial intelligence to evaluate this data stream and identify humans Unrecognized hidden print parameter relationship.

Looking at the progress of metal additive manufacturing from prototyping to production, engineers realized that a key factor in this transition is the implementation of machine vision, a method of monitoring and analysis in the process that provides real-time data during the printing process.

For metal 3D printing, this significantly improves the quality and repeatability of manufactured parts and enables the process to pass the technology readiness level (TRL). Therefore, they hope that the introduction of machine vision into their MEW system will enable the technology to reach a level of process control that can provide repeatable results and final industrial applications.

The team demonstrated how machine vision can capture and analyze important and subtle visual information to improve and expand the accuracy capabilities of the Ministry of Water and Power. Four different electric field environments were used to analyze the MEW jet stability, thereby improving the control protocol of the printer's electric field to create a thicker layer structure.

The study also emphasizes the importance of real-time monitoring of Taylor cone volume, which refers to the cone shape observed in a conductive liquid when exposed to an electric field, in order to better understand, control and predict the printing instability of MEW L .

The researchers said that the integration of machine vision and artificial intelligence also brings the technology closer to closed-loop control, significantly accelerating its TRL.

This is the advantage of artificial intelligence: it can process large amounts of data quickly, and this distribution is too monotonous, so it is difficult for the human brain. These new advances may change the MEW printer. It will now be able to use additive manufacturing. Medical devices and implants that have never been printed.

The predictive power of machine learning is increasingly used in many aspects of 3D printing. This technology has previously been deployed to improve the quality control of 3D printing, design new 3D printing alloys, and better understand the compressive strength of 3D printed building materials.

Researchers at NYU Tandon School of Engineering used machine learning tools to reverse engineer glass and carbon fiber 3D printed components, while a team from Argonne National Laboratory and Texas A&M University used machine learning to predict defects in LPBF -Printed parts.

Link to this article: Add AI and machine vision to 3D printing

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified. Large scale machining Manufacturer of medical bags, providing 3D design, prototype and global delivery services. Also offering hard cases, semi-hard EVA, soft-sewn cases, pouches and more for OEMs. All cases are made custom according to specifications with infinite combinations of materials, molds, pockets, loops, zippers, handles, logos and accessories. Shockproof, water-resistant and eco-friendly options. Medical parts, emergency response, Electronic parts, corporate, education, military, security, sports, outdoors and construction industries. Services include case concept consultation, 3D design, prototyping,rototyping,CNC Drilling Services and manufacturing.Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material