Three Advantages Of The "High-Strength Arc" Cover Of The Electrolytic Cell

PTJ Hardware 420kA electrolytic aluminum large-scale pre-baked tank cover is a "flat type" cover used in the initial construction. After 5 years of operation, its weaknesses have gradually emerged, with low strength, severe deformation, and poor airtight insulation, resulting in poor operational safety and low energy conservation and environmental protection effects in production. For this reason, in 2018, the company replaced all 296 electrolytic cell cover plates step by step with "high-strength thermal insulation and energy-saving arc" cover plates.

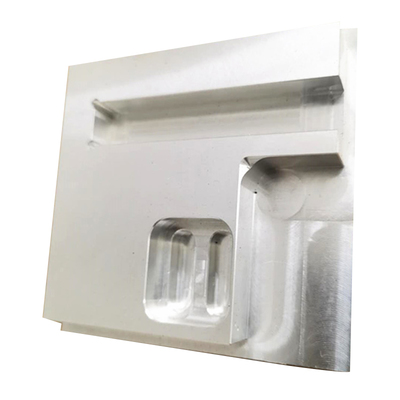

After replaced, it is effectively guaranteed in terms of safety. The movable side cover is a ladder and platform for the electrolysis production climbing tank upper maintenance tank upper equipment and replacement anode hooks and fixtures. The traditional "flat-type" mobile side cover has a large slope, and only the square tube with few contact surfaces is supported. It is difficult for the operator to stand, and it is easy to slide. During the operation, the operator must support the lower part of the slot cover to prevent safety accidents. . The "high-strength arc" cover plate adds two layers of pedal platforms, and there are anti-skid patterns on the platform, which can stand on the upper pedal platform steadily when the upper groove is operated, and the operation is safe and reliable. The curved design increases the strength of the cover plate itself, and it is not easy to be deformed after repeated use, which can further extend its service life.

"high-strength arc-shaped" cover plate also has obvious advantages in environmental protection. One of the important functions of the electrolytic cell cover is to seal the electrolytic cell, so that the generated flue gas and dust are kept in a relatively closed space, and the negative pressure formed by the purification fan is sucked away for recycling. Because the original "flat-type" cover plate is extremely easy to deform during repeated use, and the gap between each other is getting larger and larger, as time goes by, the electrolytic cell cannot be effectively sealed, and the negative pressure in the cell is not enough to remove all the flue gas. After being pumped away, a part of the flue gas generated is directly dispersed into the atmosphere through the gap of the cover plate, and the flue gas contains hydrogen fluoride gas, which will pollute the environment. The "high-strength arc" cover plate has the following two characteristics: First, the front and rear furnace doors use welded fixed door frames, and there is no side leakage after the furnace door is closed; A natural sealing state is formed. After the entire cover plate is replaced, a three-dimensional sealing effect can be achieved to ensure the negative pressure in the groove. The second is that the movable side cover uses an arc structure, which is improved in strength, and the force is more reasonable, and it is not easy to be deformed after repeated use, and the sealing performance is ensured. At the same time, the arc structure also increases the internal space of the entire electrolytic cell, which can make the aluminum oxide dust and aluminum fluoride dust flying in the cell automatically settle partly, which is more environmentally friendly than the "flat type", and appropriately reduces the flue gas purification system. load.

"High-strength arc" cover plate is also superior in energy saving and consumption reduction. Another important function of the electrolytic cell cover is to keep the electrolytic cell warm. According to measurement, 43% of the heat of the electrolytic cell is lost through the upper part of the cell, and the heat dissipation at the bottom and side of the electrolytic cell is basically constant. Reducing the heat loss from the upper part of the cell plays a very important role in energy saving in electrolysis production. The movable side cover plate covering the large area of the electrolytic cell is designed as a sandwich heat-insulating cover plate, which has a better heat preservation effect. According to the comparison before and after the replacement, the loss emitted by the cover plate after the replacement is reduced, the voltage can be reduced by 10mv, the electricity consumption per ton of aluminum can be reduced by 30kWh, and the annual electricity saving can reach 9 million kilowatt-hours. It can also reduce the insulation material on the pole by 5cm. A single tank can reduce the insulation material by about 3 tons in a cycle of pole change. Considering that the insulation material can be recycled, all 296 tanks can reduce the processing and transportation of the insulation material by more than 10,000 tons per year. It also saves a lot of costs for production. In addition, from the perspective of fluoride salt consumption indicators, after replacing the new cover plate, the unit consumption of aluminum fluoride can be reduced by 0.4kg/t-Al, and the annual consumption of aluminum fluoride can be saved by 132 tons.

After the replacement of the “high-strength arc-shaped” cover plate, the on-site environment has been significantly improved. As time goes by, the advantages in energy saving and consumption reduction will become more and more obvious.

Link to this article: Three Advantages Of The High-Strength Arc Cover Of The Electrolytic Cell

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material