The Selection Requirements Of Lathe Mechanical Spindle

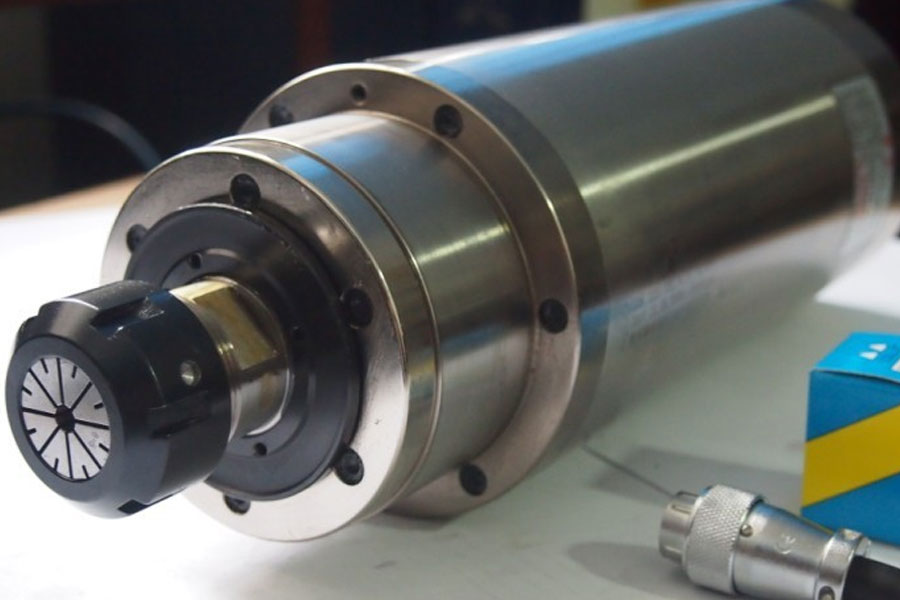

The machine tool spindle refers to the axis that drives the workpiece on the machine tool. The main shaft components are usually composed of main shaft, bearings and transmission parts (gears or pulleys). The main shaft is the most common part of the machine. It is mainly composed of inner and outer cylindrical threaded splines and transverse holes. The main shaft is the executive part of the machine tool. It mainly supports the transmission parts and transmission torque. It drives the workpiece to directly participate in the surface forming movement, and the spindle also ensures that the workpiece has the correct relative position to other parts of the machine tool.

Mechanical spindle refers to the axis that drives the workpiece to rotate on the machine tool. The main shaft components are usually composed of main shaft, bearings and transmission parts (gears or pulleys). In the machine, it is mainly used to support transmission parts such as gears and pulleys to transmit motion and torque, such as machine tool spindles; some are used to clamp workpieces, such as spindles. Except for machine tools whose main motion is linear motion, such as planers and broaching machines, most machine tools have spindle components.

The characteristics of mechanical spindles are three highs and one low (ie: high speed, high precision, high efficiency, low noise).

- 1. High speed: The mechanical spindle CNC engraving and milling machine adopts precision and high-speed matched bearings, elastic/rigid pre-tightening structure, which can reach higher speeds and achieve better cutting results.

- 2. High speed: 7:24 taper hole can ensure less than 0.005mm for installation and even radial runout. Because high-precision plus high-precision parts manufacturing can be ensured.

- 3. High efficiency: The continuous micro height can be used to change the speed, so that the cutting speed can be controlled at any time during the machining process, so that high machining efficiency can be achieved.

- 4. Low noise: The balance test shows that all those that have reached the G1/G0.4 (ISO1940-1 level) have the characteristics of low noise when the spindle is running at high speed.

The accuracy of the mechanical spindle

The movement accuracy and structural rigidity of the spindle components are important factors that determine the machining quality and cutting efficiency. The main indicators to measure the performance of spindle components are rotation accuracy, stiffness and speed adaptability.

- ①Rotation accuracy: The radial and axial runout (see form and position tolerances) in the direction that affects the machining accuracy when the spindle rotates is mainly determined by the manufacturing and assembly quality of the spindle and the bearing.

- ② Dynamic and static stiffness: Mainly determined by the bending stiffness of the spindle, the stiffness and damping of the bearing.

- ③Speed adaptability: Allowing a higher speed and speed range is mainly determined by the structure and lubrication of the bearing, as well as the heat dissipation conditions.

Link to this article:The Selection Requirements Of Lathe Mechanical Spindle

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material