What are the advantages of 3D printing tools in the production of jigs and fixtures over traditional manufacturing methods?

In the automotive development process, engineers need a large number of customized production tools, which are often designed for specific tasks and models. Ford Focus's series production alone requires more than 50 different assembly tools. These tools are initially developed in pilot plants and then 3D printed on-site in all European plants.

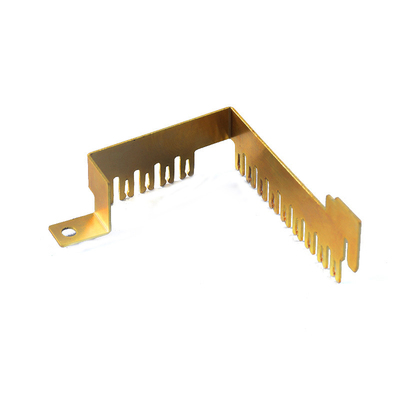

Procuring these tools through external manufacturers requires a lot of time, is costly, and slows down the development schedule. In order to optimize the workflow, Ford's additive manufacturing team integrates Ultimaker, BigRep and other brand printers into the workflow to design and manufacture assembly tools such as fixtures, jigs and measuring tools. Generally speaking, these tools are complex in design, cost-effective, fast in production, and can be produced directly on site.

In the past few years, the production methods of these tool auxiliary tools have undergone a fundamental change: from Volkswagen to Boeing, robots, etc., leading manufacturers have seen the benefits of 3D printing as a tool manufacturing method.

The importance of clamps and fixtures

Maximizing production efficiency and productivity is the main concern of manufacturers. Jigs and fixtures are manufacturing auxiliary tools used to improve the reliability, accuracy and quality of the manufacturing process, while minimizing the production cycle time and improving the safety of workers. Fundamentally, the purpose of fixtures, fixtures and manufacturing aids is to provide accurate, repeatable and interchangeable manufacturing processes while reducing production time and human error.

1. Fixture

A jig is a tool that is used to support and support a work piece, and at the same time guide a cutting or processing tool for a specific operation. The most common type of fixture is the drill fixture, which guides the drill bit to the desired position.

2. Tooling

The fixture holds, supports and positions the work piece during processing or assembly (but does not guide the cutting tool). The clamps are usually connected to the machine, and each clamp must be constructed to fit a specific part or shape.

Fixtures and fixtures are essential for optimizing the manufacturing process, and their benefits include:

1.Reduce waste

2.Improve process accuracy and repeatability

3.Reduce required skill level (operating fixtures and fixtures)

4.Improve productivity

3D printing tools: breaking tradition

Traditional manufacturing methods require the fixtures and fixtures to be numerically controlled or manually welded and assembled. This process can take days (or weeks, if outsourced), especially because machining parts requires intensive planning and skilled machine operators.

Not surprisingly, using traditional manufacturing methods will result in long delivery times and high production costs, with little flexibility in new design changes.

However, 3D printing is ideal. With a 3D printer, you can produce fixtures and fixtures on demand, the price is only a small part of the material cost, and the processing can be repeated as needed.

Why 3D printing?

1. Faster lead time

One of the main benefits of 3D printing is the speed of part production. Since 3D printing is a digital manufacturing process using 3D CAD models, all that is needed is the legendary CAD model, and your part may be printed within a few hours.

This is of great benefit to making jigs and fixtures. In traditional manufacturing, mold production may take days or even weeks, and involves multiple processing steps. However, with 3D printing, most of the manufacturing process is automated, requiring less human intervention and speeding up the production process.

There are many real-life cases: Volkswagen Autoeuropa, the largest car factory in Portugal, reported that it saved 89% of time by 3D printing jigs and fixtures. Research conducted by Stratasys tells a similar story: According to the manufacturer, 3D printing jigs and fixtures can lead to a reduction in preparation time of up to 90%.

The speed at which jigs and fixtures are produced by 3D printing means that it is also ideal for multiple iterations of equipment-promoting innovation and new design changes.

Generally, multiple iterations can be designed and printed on the same day. In contrast, the cost of using external suppliers is high, the use time is long, and the benefits of additive manufacturing are obvious.

These benefits mean that engineers do not have to experience extended development cycles and long lead times between receiving iterations from the machine shop. They have the freedom and flexibility to make design changes before production.

2. Reduce costs

In addition to saving time, 3D printing also greatly reduces production costs. Usually, the production of puzzles, fixtures and other mold equipment is outsourced to external suppliers.

In contrast, 3D printing challenges this approach by allowing manufacturers to bring technology inside. This new strategy-low volume, in-house tool manufacturing-means that manufacturers can cut outsourcing expenditures.

For example, Liberty Electronics, a Pennsylvania contract manufacturing plant that produces high-end assemblies for the military and aerospace industries, saves 85% of the cost of custom tools through internal 3D printing rather than outsourcing.

Inventory is another area where manufacturers can drastically reduce 3D printing expenses. Additive manufacturing does not need to store tools and equipment, but achieves on-demand manufacturing, so tools can be produced when needed.

Finally, because 3D printing is an additive process, not a subtractive process, manufacturers can easily minimize material waste, thereby reducing material costs.

3. Improve ergonomics

Since jigs and fixtures require physical handling by workers on the production floor, making lightweight parts that are easy to handle should be the manufacturer’s top priority.

Here, 3D printing can greatly help by losing weight. For example, high-performance materials are excellent alternatives to metal cutting processes and provide lighter options. Lighter tools also mean that workers on the production floor are easier to use.

Additive manufacturing enables engineers to create improved tools to meet the exact requirements of workers.

Bob Heath, an AM application engineer at Eckhart, one of the leaders in advanced industrial solutions, said that the harsh assembly environment and repetitive tasks can cause incredible harm to employees. Designing customized ergonomic tools that are much lighter than traditionally designed tools is a benefit of Eckhardt's additive process.

The company continues to enhance the ergonomics of 3D printing tools by integrating end-user feedback, while making the tasks of workers on the assembly line lighter, safer, more repeatable, and more accurate.

For example, for an assembler who must install wiper blades on new cars entering the station every 45 seconds, this is an ergonomic nightmare.

Therefore, Eckhart cooperated with Wuhan Yicheng 3D to develop a 3D printing jig, which is located outside the motor body of the wiper and assists the operator by sucking the tool onto the windshield of the vehicle.

The fixed position created by the new fixture allows assemblers to install wiper blades consistently and eliminate any rework or quality issues downstream.

4. More types of materials

From plastic and metal to rubber and wax, 3D printing offers a variety of materials. Multi-material 3D printing is a rapidly growing area of interest, combining materials to create new materials with enhanced mechanical properties. For example, 3D printed parts can be chemically and heat resistant, or have UV stability.

One of the most important effects of fixtures and fixtures is the development of high-performance materials such as PEKK or ULTEM and composite materials, which can create strong and lightweight mold parts with enhanced mechanical properties.

5. Improve performance

3D printing can help improve the performance of fixtures and fixtures by providing a simpler way to create new and improved designs. In the past, achieving this goal would be a daunting task due to the effort and expense required to produce new manufacturing devices using traditional methods.

AM can add functions such as serial numbers, manufacturing dates, and other key data to enhance inventory management and tracking.

Components separated during processing can be combined together during 3D printing. This will minimize interstitial space and unnecessary accumulation of dust and debris (such as machining tools).

6. Customization

Finally, 3D printing facilitates the creation of customized products. Coupled with the ability to create complex geometries, this technology can easily be used to produce complex custom tools that would otherwise be impossible with traditional manufacturing methods.

Ford uses a large format (1m³) 3D printer to manufacture jigs and fixtures

If the number of workpieces is small, the cost of 3D printing manufacturing is relatively low; the tools are lighter than traditional methods and can adapt to additional needs faster. Compared with the cost of traditional tools in conventional production, each tool can save 1,000 euros for printing and assembly auxiliary tools, such as jigs and jigs. From the original external contract, including design and manufacturing, which averaged 10 weeks, to now even complex assembly fixtures can be completed within 10 days at the latest. The Bigrep pro3D printer used by Ford today has a molding size of 1 cubic meter, which can be used to print large industrial parts.

The advantage of FDM 3D printing lies in the material. A large number of consumables and a wide range of material characteristics provide the correct solution for practical applications. With only one additive manufacturing process, the production equipment can meet the requirements of the most diverse applications and operating environments.

The range of consumables and their material properties is almost endless: strength, elasticity, heat resistance, strength, resilience, and durability are all within the scope of predictable changes. For 3D printing technology, the most important thing is to be able to print with quality and quantity without losing material properties.

Another key factor in the use of FDM 3D printers is the open consumable system. 3D printing production tools can be individually adapted to consumables with different material properties from different material manufacturers to achieve their respective applications and manufacturing. This feature of 3D printers is particularly prominent in production equipment, tools and assembly aids, showing the disruptive potential of the additive manufacturing process and has already brought about exemplary changes. Especially in terms of assembly tools, the application program is not only very diverse in form, but also has a wide range of applications.

Link to this article:What are the advantages of 3D printing tools in the production of jigs and fixtures over traditional manufacturing methods?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material