See how 3D printing and green casting are cleverly combined?

Green casting refers to energy-saving and environmentally-friendly casting. It is to create a green, energy-saving and environmentally-friendly casting production base on the basis of the traditional foundry industry. It starts with product design, raw and auxiliary materials, energy consumption, and clean technology. Equipment such as degassing and noise reduction can reduce the discharge of major pollutants, while increasing the green area of the plant and improving the natural environment of the plant.

Rapid casting technology

The casting process formed by the combination of 3D printing technology and traditional casting technology is called rapid casting technology. Rapid casting is the use of rapid prototyping technology to directly or indirectly print out casting molds (silicone, metal, plastic, nylon, photosensitive resin, carbon fiber), and disappear Mold (foam), wax sample, sand mold, core or shell, and then combined with traditional casting process to quickly cast metal castings.

The use of 3D printing technology for rapid casting and forming can significantly improve the traditional casting industry’s poor production environment, low energy utilization, serious environmental pollution, and more potential safety hazards. While ensuring quality, it effectively improves production efficiency. There is no workshop design. The crane and "zero emission" reduce the labor intensity of employees and improve the working environment of employees.

Application of rapid casting technology

SLS/SLM selective laser sintering/melting molding

Main materials: metal powder, nylon powder, coated sand, wax material;

main application:

a. Use metal powder to make metal products in the sample stage or single small batch products or make molds during mass production.

b. Use nylon powder to make sand casting molds instead of wooden molds in sample stage or single-piece small batch products;

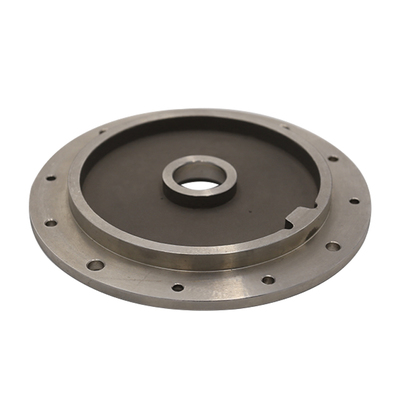

c. Use coated sand to make sand cores, such as impeller sand cores, in the sample stage or single-piece and small-batch product stage;

d. Use wax to make fusible molds at the sample stage or single-piece and small-batch product stage;

SLA laser three-dimensional curing molding

Main material: photosensitive resin

main application:

a. Make resin prototypes for precision casting, instead of traditional wax molds;

b. Make molds for casting instead of wooden molds.

3DP three-dimensional printing

Main materials: furan, phenolic binder; various sand materials (quartz sand, pearl sand, ceramic sand, etc.);

Main application: production of sand molds and sand cores for complex parts with various specifications in the sample stage or small batches in a single room;

3D carving;

Main material: foam/wood;

main application:

a. Use foam materials to make disposable molds for the disappearance method;

b. Making wooden molds for larger products;

Link to this article: See how 3D printing and green casting are cleverly combined?

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material