Blockchain will bring new life to 3D printing!

Although many blockchain projects around the world are paying attention to the future development of technologies such as smart contracts, data sharing protocols and encryption tracking for trade financing, risk management, logistics tracking and other multi-party applications, there is no doubt that they are absolutely Most of them are still in the early stages of development, and it is still too early to predict their impact on world trade. When it comes to the impact of blockchain on the science and technology ecology, many people have already predicted that the first innovation will be the development of the once-suspended 3D printing industry.

How will this happen?

First, let's take a look at 3D printing. 3D printing is a technology that builds objects based on digital model files and builds them layer by layer. It has mature application cases in various fields such as industrial applications, construction industry, medical field, national defense and military industry, cultural creativity, etc. It is therefore known as the pillar industry of Industry 4.0.

However, affected by objective conditions such as high cost, limited data interoperability, and the inability to effectively and timely docking between supply and demand, despite the wide application of the 3D printing industry, the output value of the entire industry is still sluggish.

The development of blockchain technology can free the Internet of Things, 3D printing and other automation technologies from physical limitations in a timely manner, and adapt to a decentralized, on-demand production mode. This application scenario not only requires technological development, but also requires manufacturers to adjust to a more equal and open mindset, optimize competition, and achieve a balance of cooperation. Mipai MIP.AI is a digital distributed manufacturing chain (blockchain 3D printing).

Forward-looking solutions

So far, almost all large manufacturers and shipping trading companies still tend to look at the supply chain from the perspective of the owner. The supply relationship in the middle is often like a club. The supplier only needs to start follow-up cooperation after establishing trust with the buyer.

In layman's terms, the lack of trust among designers, users and manufacturers has created a bottleneck in the development of the industry. There are three hidden worries: designers are unwilling to disclose the results, and the lack of supervision and other issues will also make users not satisfied with the quality of the product. For manufacturers, the high cost and non-sharing of information are also a major obstacle.

Inevitably, these companies are inclined to the application system of the permission chain (permission chain: different from the typical shared blockchain such as Bitcoin and Ethereum. The permission chain refers to all the nodes participating in the blockchain, which are passed through Permitted, only permitted nodes can be added to the blockchain), which means that this distributed ledger must be centrally managed by major retailers or manufacturers. It is the emergence of these "permission chains" that have strengthened the "club"ization of these enterprise alliances.

To solve this situation, the first thing we need to break through is to open doors for many suppliers who have not yet established a trust relationship. Just imagine, if the 3D printer can uniquely identify the encryption protocol, if the data generated during the transaction is complete, without anyone's permission, and can be completely open to record on the blockchain registry. For users, how much unnecessary trouble is saved.

Obviously, all of this relies on more technological improvements to give the blockchain greater scalability-including the development of related payment channels and the realization of more interoperability agreements.

It also requires standardized certification of built-in chips. In this way, the technology and industrial information network connected by printing devices, sensors and other related devices can provide data for these decentralized systems more reliably. .

Although this scenario is still in the imaginary stage, this experimental and forward-looking vision has painted a completely different picture of the global economy and will trigger a series of new challenges.

Decentralized work form

Moog Inc., a precision parts manufacturer in the United States, realized that in the case where the integrity of the software shared by different printing devices cannot be confirmed, whether it is a manual operation error or a network hacker attack, the manufacturer cannot be in the process of specific operations. Ensure that there are no defects in 3D printed products. Therefore, their innovative R&D department once put forward the idea that as long as there is a distributed database based on blockchain technology, it can more effectively track the entire development process of software code transferred from one engineer to another. Can quickly realize point-to-point information exchange and resource sharing.

If blockchain technology can be used to change and break through the existing bottlenecks, it will significantly change the ownership structure of the entire manufacturing industry. Enable 3D printing manufacturers to achieve on-demand production, immediate production, and nearby production, reducing various costs to the greatest extent. Effectively avoid the increased cost due to intermediate links and transfer to the final product. Labor-intensive factories and product assembly lines are about to become a thing of the past. Many production steps from primary raw materials to finished products will gradually be simplified and efficiency will be greatly improved.

More importantly, the protection of intellectual property rights for personalized customized products will also receive more attention.

Today's production industry is about to gradually evolve from an orderly, overlapping and repeated redundant heterocyclic nodes to a more controllable supply chain. While the logistics link is constantly moving closer to the terminal, the payment method is also returning to the upstream accordingly, and the team-driven may be called the final work form.

Just like film and television production and music production, the entire manufacturing industry will also form a mode of collaboration and cooperation among multiple intellectual property parties.

Innovative labor concept

Regardless of whether this model can be truly realized or not, in terms of the vision it advocates, it is imperative to further liberate the labor force from the manufacturing industry and at the same time give full play to the creativity and innovation of science and technology. For a large number of service providers who rely on labor for their livelihoods, the bleak prospects can already be expected. For designers and brand operators, they will also have greater rights.

In order to create a fairer, more harmonious, and more innovative society, we urgently need a more driving creative model, allowing inventors to continuously get better designs from a large number of new "players". This means that industry barriers are broken, the dominant position of mainstream old players is challenged, and more and more new ideas can get opportunities.

Of course, under this trend, building a decentralized industrial structure has become a top priority. With the development of the global economy, people are paying more and more attention to the protection of personal data and intellectual assets. It has become a general necessity to select and trade personal data in a personalized way.

Link to this article: Blockchain will bring new life to 3D printing!

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

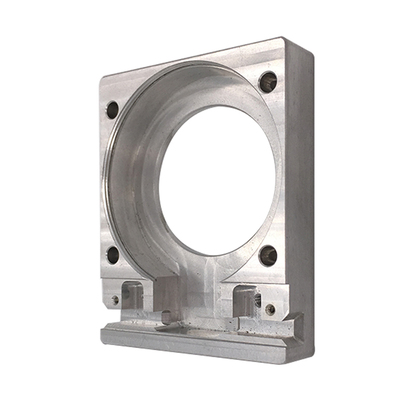

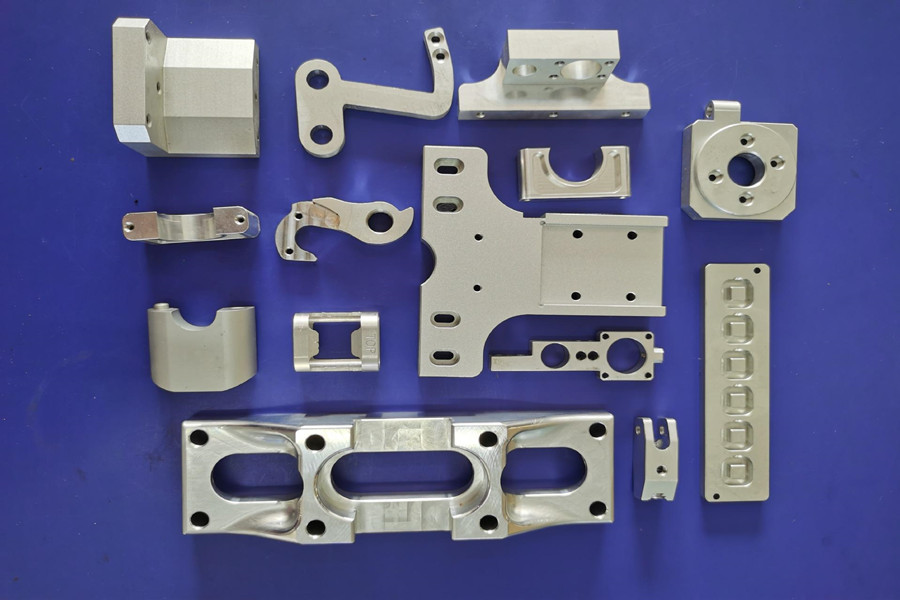

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

PTJ® is a customized manufacturer that provides a full range of copper bars, brass parts and copper parts. Common manufacturing processes include blanking, embossing, coppersmithing, wire edm services, etching, forming and bending, upsetting, hot forging and pressing, perforating and punching, thread rolling and knurling, shearing, multi spindle machining, extrusion and metal forging and stamping. Applications include bus bars, electrical conductors, coaxial cables, waveguides, transistor components, microwave tubes, blank mold tubes, and powder metallurgy extrusion tanks.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material