3D printing complex titanium alloy inserts

During the space launch process, the cost of putting each kilogram into the satellite orbit is about US$20,000, and every gram saved will help improve the efficiency of space exploration. Materialise collaborated with the engineering department of Atos, a global digital services company, to redevelop a titanium alloy insert that is widely used in satellites.

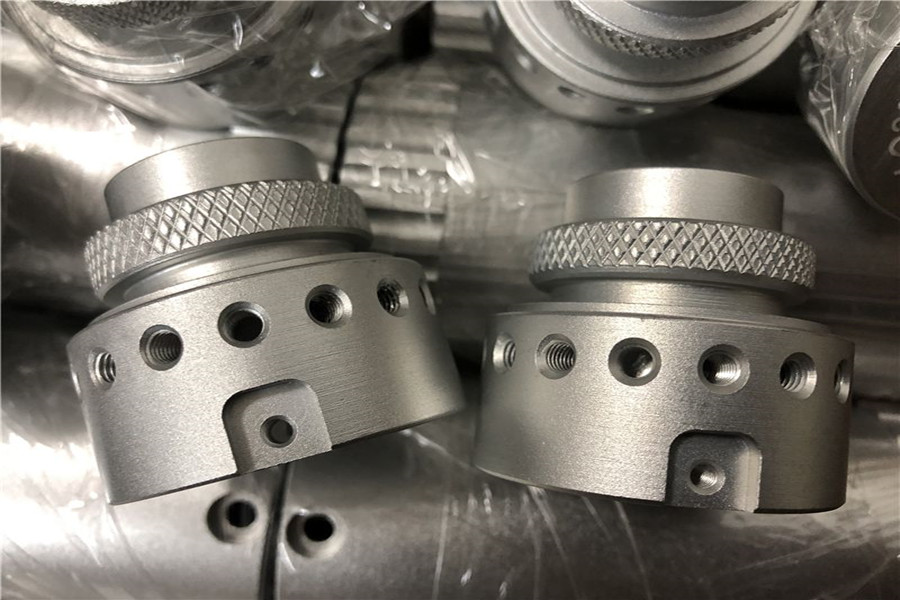

When designing or manufacturing spacecraft components, the biggest challenge is to optimize weight without sacrificing the strength or performance of the components. Titanium alloy inserts are widely used in the aerospace field, and are used to transfer high mechanical loads in structures such as satellites. With the exquisite optimized design and metal 3D printing, the weight of the new titanium alloy insert is only one-third of the original weight, and the performance has also been improved.

Inserts into sandwich panel structure

Titanium alloy inserts are usually used to connect other equipment with satellites. Such inserts bear high loads and require lifting of large and heavy structures. This means that they must have a high strength-to-weight ratio, high strength and rigidity, and at the same time they must be very light. These inserts are placed in the composite structure sandwich panel, which is very common in aerospace structures, and transfer the load through the combination with the sandwich panel.

Traditional inserts are usually made of aluminum alloy or titanium alloy by machining, and the inside of the brick shape is completely solid and high in quality. In addition to the high cost of materials, heavy components will increase the operating cost of the spacecraft each time it is launched. Metal 3D printing provides an opportunity to reduce the weight of aerospace structures.

Use 3D printing to optimize design

Engineers face the challenge of changing traditional thinking. This design aims to meet all requirements from the concept stage to the manufacturing stage. Relying on its expertise in aerospace engineering and structural simulation, Atos designed this new component from the inside out to improve its overall performance.

Through 3D printing, the internal space of the object can be designed with a hollow or lightweight structure. The engineers of Materialise and Atos started by reducing the amount of material used inside the components. The R&D team used advanced technologies such as topology optimization and lattice structure design to reduce the mass of inserts from 1454 grams to 500 grams.

In addition to reducing weight, the team also solved the problem of thermoelastic stress in the original design. Since these inserts have been installed during the curing process of the carbon fiber reinforced polymer plywood, they are subject to thermoelastic stress. The optimized design reduces the influence of these stresses and improves the load distribution, extending the service life of the insert.

The cross section of the insert shows the lightweight structure inside

The Materialise metal 3D printing plant in Bremen was responsible for the production of two newly designed titanium alloy (TiAl6V4) inserts. Metal 3D printing has proven its great potential in the aviation field, and there has never been any means to achieve such a fast delivery time.

Atos Spain’s Director of Mechanical Engineering commented: “Reducing weight will help increase the payload of satellite equipment and save a lot of cost per launch. It is precisely because of this in such a short period of time that this has been created in the field of metal additive manufacturing. This highly complex product has made Atos and Materialise the leading providers of metal 3D printing solutions."

From past cases, we can see that materialise has almost penetrated into various application fields, constantly challenging the status of traditional processing methods, constantly exploring the profound application of 3D printing in traditional manufacturing, advancing changes, and promoting the development of 3D printing. So far, there is only one materialise.

Link to this article: 3D printing complex titanium alloy inserts

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material