Motorcycle tires using 3D printing technology

Michelin recently launched a new generation of motorcycle tires MICHELIN Road 5, which is also the first motorcycle tire produced by Michelin made of metal 3D printed tire molds. According to official Michelin news, MICHELIN Road 5 tires can still maintain good braking performance after a mileage of more than 4,800 kilometers, which means that the tires can be used to the maximum level of wear. So, what technologies did Michelin use when designing and manufacturing this tire? What role does metal 3D printing play in tire mold manufacturing?

Break through the processing limitations of complex textures

A notable feature of MICHELIN Road 5 is that the tire pattern can be changed. When the mileage increases, the tire will have grooves and the tread pattern will increase, so as to maintain the best drainage effect. This technology is Michelin's XST Evo pattern technology.

Michelin used metal 3D printing technology when manufacturing this tire pattern. More precisely, Michelin used metal 3D printing technology when manufacturing the cavity pattern in the MICHELIN Road 5 tire mold.

In addition to metal 3D printing molds, the new technology applied in Michelin MICHELIN Road 5 also includes new rubber materials, and ACT + technology (adaptive casing technology) that can achieve progressive rigidity at the shoulder of the tire. These two are also the key to ensuring tire performance. technology.

The tire pattern is an important and complex processing difficulty. The precision of its processing directly affects the accuracy and quality of the tire, even the safety of the tire, the comfort of driving, and so on. The structure of the pattern often presents a three-dimensional distortion in space, and the tire pattern has the characteristics of many radians and many angles. It is difficult to accurately complete using traditional processing methods. Even if the EDM technology is used, there are some difficult problems to solve.

Michelin cooperated with Fives to develop and manufacture Michelin tire molds through metal 3D printing equipment, breaking through the complex texture manufacturing that is difficult to achieve with traditional casting and machining technologies. Traditionally, in the processing of tire patterns, the processing procedures are highly concentrated, mainly milling, but because the processing angles and corners are not uniform, some patterns have thin and tall small ribs or narrow and deep ribs. Small grooves, or even irregular surface pits and pits, so the requirements for the tool are relatively high.

Several processes for tire mold processing

Since the design and manufacture of the radial tire active mold is difficult to control, the mold’s working surface accuracy is not easy to control, the mold opening and closing mechanism is coordinated, and the parting surface processing requirements are higher. The working profile has a greater impact. In addition, any error in the tool path planning algorithm in machining will directly affect the quality of the tire. 3D printing technology can complete the complexity of shapes that are difficult to achieve by traditional machining. More complex, better grip and stable performance are undoubtedly the high ground for high value-added tires.

It is not only a problem of accuracy, but because many patterns of tire molds are too deep, interference will also occur during the processing of the tool, which brings a lot of restrictions on the design of the pattern. The replacement cycle of tires has become shorter and shorter, which has brought considerable pressure on design, machine tool programming, tool configuration and procurement, etc. Metal 3D printing has solved the problem of tool interference very well. When complexity and manufacturability are no longer the biggest factors that plague tire mold manufacturing, 3D printing has released the convenience of tire product design iteration. It gave birth to new types of tire manufacturing capabilities.

Michelin has used metal 3D printing technology to manufacture tire molds for the travel and heavy-duty truck tire series, and through these molds have produced MICHELIN Premier A/S, MICHELIN Premier LTX, MICHELIN CrossClimate, MICHELIN X Line Energy, MICHELIN X-Multi Series of tires. Michelin once again used metal 3D printed tire molds in the manufacture of MICHELIN Road 5 motorcycle tires. From this, it can be felt that Michelin is firmly grasping metal additive manufacturing technology to strengthen its core competitiveness of high-performance tire products.

Link to this article: Motorcycle tires using 3D printing technology

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

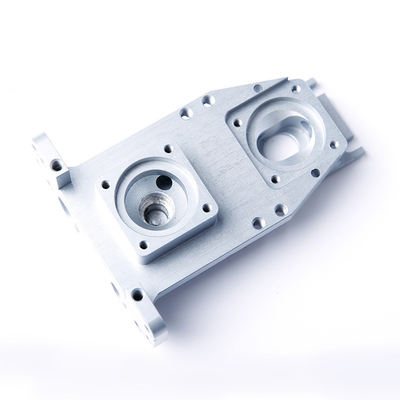

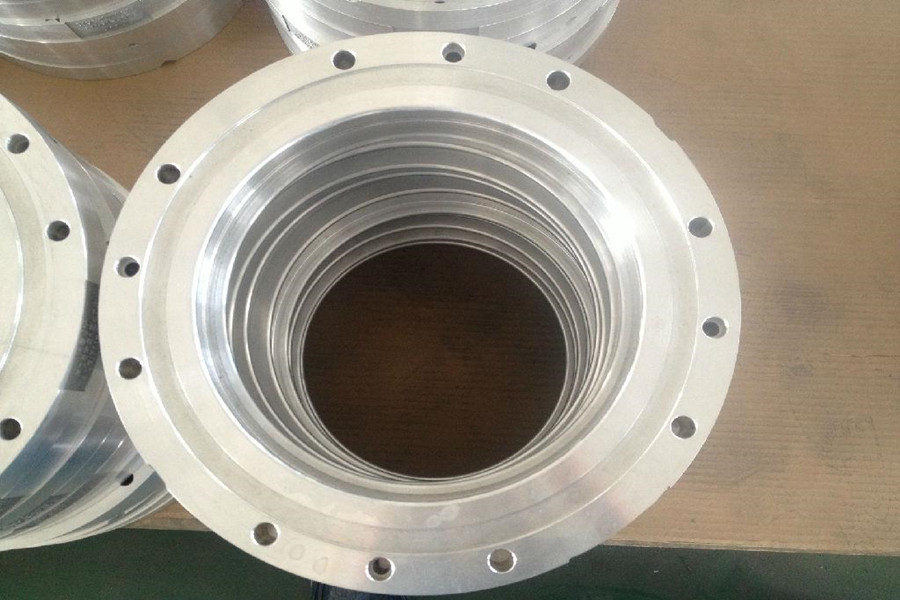

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom manufacturer of precision fabricated parts made from aluminum parts, brass parts, bronze, copper parts, high yield alloy, low carbon steel investment casting, high carbon steel and stainless steel alloy. Capable of handling parts up to +/-0.0002 in. tolerance. Processes include cnc turning, cnc milling, laser cutting,.ISO 9001:2015 &AS-9100 certified.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material