3D printing industry investment continues

On May 10, the reporter learned that the consulting agency Wallace released the 2019 3D printing industry annual report: The 3D printing industry scale in 2018 was 9.68 billion U.S. dollars, and it was predicted to reach 15.8 billion U.S. dollars by 2020, and it may be in 2022. Climbing to 23.9 billion U.S. dollars, it may reach 35.6 billion U.S. dollars in 2024.

Popularity climbs: the investment boom continues, and the players start to increase

A few days ago, the consulting agency Wallers released the 2019 3D printing industry annual report: The 3D printing industry scale in 2018 was 73.4 US dollars, and it is predicted that by 2020, the 3D printing industry scale is expected to reach 15.8 billion US dollars (approximately 106.1 billion yuan) ), it may climb to 23.9 billion U.S. dollars (approximately 160.5 billion yuan) in 2022, and it may reach 35.6 billion U.S. dollars (approximately 239.1 billion yuan) in 2024.

It is understood that the global additive manufacturing industry has achieved rapid growth. According to the "China 3D Printing Industry Market Demand and Investment Potential Analysis Report" released by the Foresight Industry Research Institute, the scale of the global 3D printing market has increased year by year from 2010 to 2018. The speed fluctuates downward. Among them, the global 3D printing market in 2012 was US$2.3 billion, a year-on-year increase of 35.29%, the largest growth rate in the past 9 years. As of 2017, the global 3D printing global market has grown to 7.34 billion U.S. dollars, a year-on-year increase of 21.12%. From 2016 to 2017, the growth momentum of the global 3D printing market has slowed down, but it is still at a high level. Entering the end of 2018, the global 3D printing market reached 9.795 billion US dollars, a year-on-year increase of 33.5%. From the perspective of three years, this growth rate has reached 24.4%. It is difficult for other industries to achieve such high growth when economic development is slowing down.

Companies from all walks of life are generally optimistic about the value of 3D printing technology to various industries. Currently, companies investing in 3D printing technology research and development include well-known companies such as Airbus, Adidas, Ford, and Toyota. According to public statistics, in 2016, there were 97 companies in the world capable of independently "researching and producing" 3D printers; in 2017, there were 135 companies; by 2018, it had increased to 177 companies. The number of systematic players in the industry has begun to increase, which means that printer-related R&D and manufacturing technologies are becoming more mature.

Multi-angle expansion and development of the industry: Customization capabilities enable technology to successfully penetrate into various fields

The vigorous development of the 3D printing industry is mainly due to the high customization capabilities of the industry, and the applicable scenarios are quite diverse. At present, the in-depth integration of various industries and scenarios is also relatively optimistic. In terms of industry, there have been certain application results in the clothing, traditional automobiles, aviation, construction, weapons, medicine, robotics and aerospace industries. Representative companies that currently use 3D printing in their manufacturing processes include Airbus, Boeing, and BMW.

1. The field of ready-to-wear

In 2012, Nike used 3D printing technology to design the shoe "Vapor Laser" for American football players. It adopts integrated molding technology to effectively improve the efficiency of player movement. In 2018, New Balance debuted its running shoes designed for athletes for the first time, which can use 3D. The printing technology is customized to fit the foot shape completely.

2. Traditional automobile field

In 2014, Swedish super sports car manufacturer Koenigsegg used 3D printing technology to produce parts for its One:1 model. The manufacturer also has its own parts 3D printing production line; American engineering companies Kor Ecologic and 3D The Urbee, co-manufactured by printer manufacturer Stratasys, is the world's first car to use 3D printing technology to print the body and windows of the car.

3, aviation field

As the aircraft not only has a long manufacturing cycle and a lot of consumables, 3D printing technology can effectively improve the utilization rate of materials and shorten the manufacturing time. In 2015, Airbus announced that more than 1,000 parts of its model A350 XWB were manufactured by 3D printing.

4, the field of construction

Nowadays, 3D printing technology is mainly used to build models in the field of architecture. In the past, most of the architectural models used for display were hand-made, which was time-consuming and difficult to meet the psychological expectations of customers. 3D printing can fully present the design drawing and effectively reduce the production time.

The University of Southern California has developed a technology that can directly print out houses. In the future, it is expected to "print out" a building within 24 hours and achieve the goal of zero consumables.

5. Weapons

In 2012, a civil organization in the United States designed a gun design that can be mass-produced through 3D printing; in 2014, a Japanese man was arrested for printing a gun that could fire by himself and spreading the design for looting, becoming the first in the world to print a gun design. A person sentenced for a weapon.

6, the field of medicine

3D printing has been successfully used in organ transplantation and medical device manufacturing. At present, in organ transplantation, the pelvis and lower jaw have been successfully replaced, and it has also been used in the reconstruction of patients with facial disfigurement. It is expected to help the development of orthopedics, hearing aids and dental related technologies in the future.

7, the field of robotics

Due to the complex parts and components of humanoid robots, most of them are assembled manually, and there are still challenges in mass production. 3D printing can effectively solve the assembly problem, making the humanoid robot realize the mass production plan. At present, companies around the world have developed humanoid robots that can be manufactured by 3D printing technology.

Rigid demand has not yet formed: C-end sales have grown amazingly, but the share is still small

Not only is the application in the industry beginning to spread, 3D printers are also gradually becoming C-end consumers.

The price of general consumer-grade 3D printers is generally below US$5,000 (about 33,580 yuan), and is mainly for general users, such as individual consumers, schools, and families.

1. Individual consumers/households

Consumer-grade 3D printers on the market are still used by individual consumers for entertainment rather than practicality. The consumer groups are mostly technology trend followers, but some furniture (such as coat hooks, door handles, etc.) have been independently produced through 3D printing.

2. School

STEAM education is currently the largest application field of 3D printers in schools. Through printing technology, the school no longer needs to purchase expensive programming training hardware equipment. Students can design, print and build models by themselves, which can train various abilities better than general STEAM education. In 2015, a total of 278,000 consumer-grade 3D printers were sold worldwide, and Wallace’s latest data shows that nearly 529,000 consumer-grade 3D printers were sold globally in 2018, and shipments have explosively grown by nearly 2 times. , But its share of overall scale is still small.

But overall, the development of the C-end market is still optimistic. As the technology of manufacturing machines and printing becomes more mature, it will drive down the cost and price of printers, and greatly expand the applicable scenarios for general consumers, which can play the same role as daily home appliances.

Future development trend: open up the use of stand-alone open source materials, faster printing speeds and lower prices

On the whole, the development prospects of 3D printing technology are still worth looking forward to.

Yiou think tank believes that the future development trend will mainly focus on three aspects: open up the free use of multiple materials in a single machine, increase the printing speed of 3D printers, and reduce the price of 3D printers.

Exploring the free use of a single machine in a variety of materials means that because most of the current 3D printers can only use a single material (such as silica gel or iron), the future will focus on the development of printers that can use multiple materials. Significantly broaden the application scenarios that a single machine can use.

The faster printing speed and lower price also help 3D printers penetrate into commercial and civilian scenes. 3D printing technology can make full use of materials and achieve a high degree of customization for users. As the technology matures, it can provide strong design and manufacturing support for various industries in a more environmentally friendly mode.

Link to this article: 3D printing industry investment continues

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

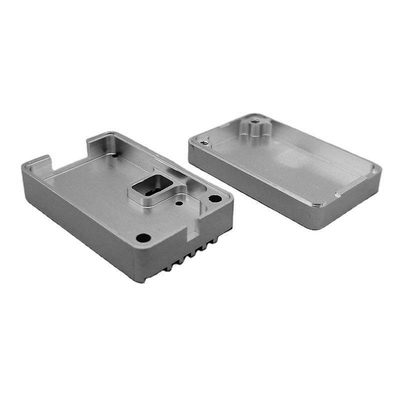

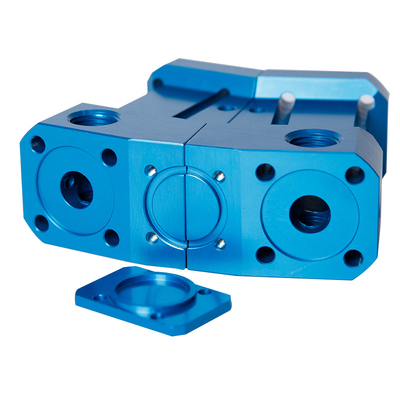

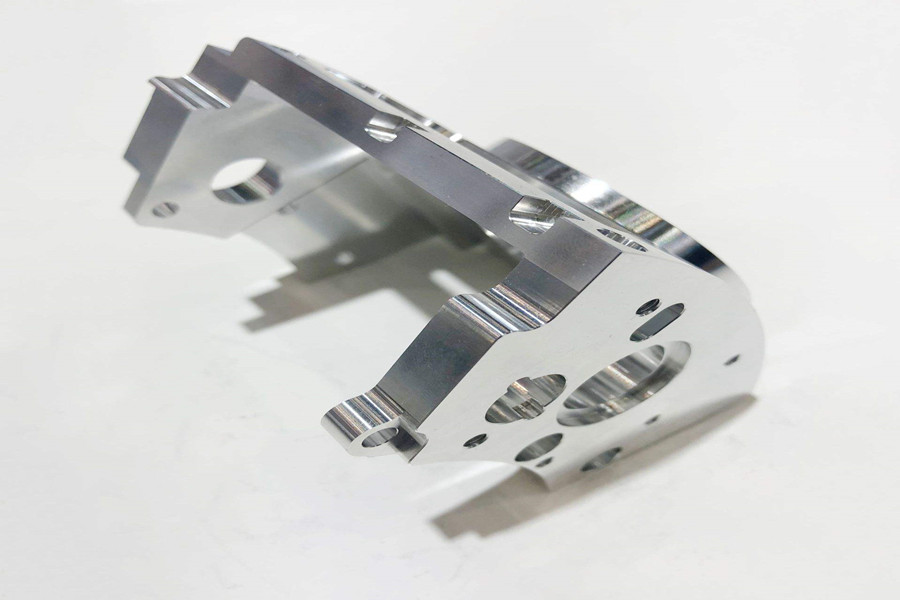

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material