Research on Dissolving Ultrasonic Cleaning Process

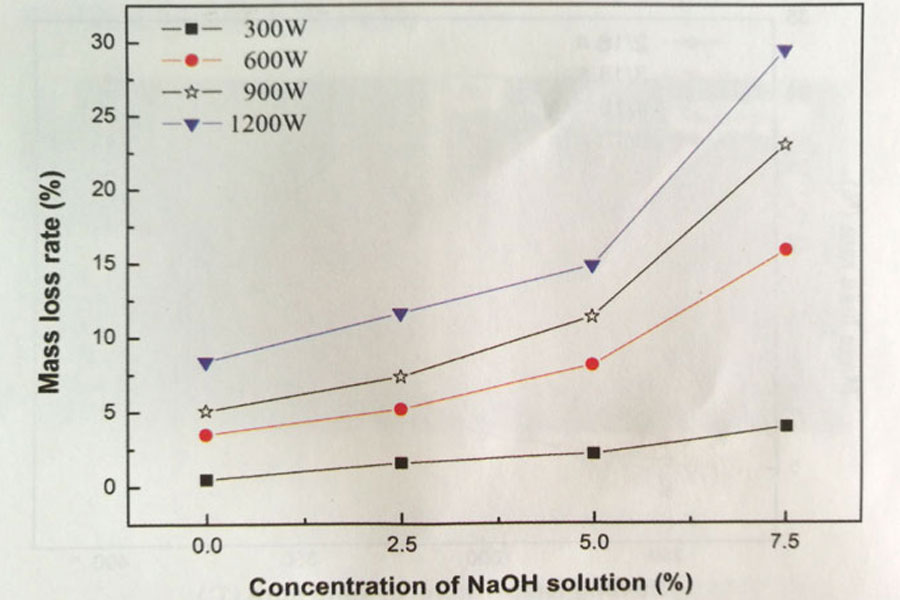

The core is cleaned by the cleaning process of dissolving ultrasonic wave, and the influence of different NaOH solution concentration, ultrasonic power and core heating temperature on the efficiency of dissolving ultrasonic cleaning is studied. When the heating temperature of the core is 300℃, the influence of different NaOH solution concentration and ultrasonic power on the efficiency of dissolving ultrasonic cleaning.

The falling sand rate of the core increases with the increase of the concentration of the NaOH solution, and its effect mechanism is the same as that of the dissolution vibration; the falling sand rate of the core increases with the increase of the ultrasonic power, which is different from the dissolution vibration cleaning process The point is: when the cleaning fluid is water, the increase of ultrasonic power will slightly increase the cleaning efficiency of the core, which shows that the clean water dissolution and ultrasonic cleaning process still have a certain cleaning effect. In the process of ultrasonic cleaning, with the increase of the ultrasonic action time and power, the temperature of the cleaning fluid increases slightly (about 35°C).

In the dissolving ultrasonic cleaning process, the main mechanism of ultrasonic cleaning is the "cavitation effect" of ultrasonic in the liquid. Ultrasonic "cavitation effect" means that when ultrasonic waves propagate in the cleaning liquid, the cavitation nuclei (microbubbles) in the liquid generate ultrasonic vibration under the action of the positive and negative sound pressure cycles of the ultrasonic waves. When the sound pressure (energy) reaches a certain value, The microbubbles expand rapidly and then suddenly close. When the microbubbles are closed, a shock wave will be generated, causing the liquid to generate local high pressure, local high temperature and overall temperature rise. This phenomenon is called the transient "cavitation effect" of ultrasound. The impact of high pressure will destroy the bonding bridge of the core, so as to achieve the purpose of cleaning the core; in addition, the local high temperature can also accelerate the chemical reaction rate of si0. and NaOH, which can quickly clean the core: when the ultrasonic power increases, the sound Strong increase and cavitation strength increase, which is conducive to the cleaning of the core.

In addition to the main effect of ultrasonic cavitation on core cleaning, ultrasonic vibration itself also plays a certain role in cleaning. Ultrasonic vibration causes a relatively large vibration speed and acceleration of the medium in the cleaning fluid, which causes frequent and intense impacts on castings and cores. In addition, the ultrasonic cavitation process will also cause other effects, such as thermal effects (local high temperature and high pressure or even overall temperature rise) and activation effects (hydroxyl radicals generated in the solution), etc. The activation effect provides thermodynamic conditions for chemical reactions to clean the core with clean water ultrasonic waves. This also verifies that the clean water dissolution and ultrasonic cleaning process described above still has a certain cleaning effect.

Link to this article:Research on Dissolving Ultrasonic Cleaning Process

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com/,thanks!

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

3, 4 and 5-axis precision CNC machining services for aluminum machining, beryllium, carbon steel, magnesium, titanium machining, Inconel, platinum, superalloy, acetal, polycarbonate, fiberglass, graphite and wood. Capable of machining parts up to 98 in. turning dia. and +/-0.001 in. straightness tolerance. Processes include milling, turning, drilling, boring, threading, tapping, forming, knurling, counterboring, countersinking, reaming and laser cutting. Secondary services such as assembly, centerless grinding, heat treating, plating and welding. Prototype and low to high volume production offered with maximum 50,000 units. Suitable for fluid power, pneumatics, hydraulics and valve applications. Serves the aerospace, aircraft, military, medical and defense industries.PTJ will strategize with you to provide the most cost-effective services to help you reach your target,Welcome to Contact us ( [email protected] ) directly for your new project.

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material