New low-cost thermoelectric materials can cool summer auto parts

On August 8th, according to foreign media reports, in the summer, the steering wheel of the car became hot and hard to handle, but the new thermoelectric material can solve this problem. Due to the lack of materials that can maintain high efficiency at room temperature and at the same time are inexpensive, the popularization of thermoelectric devices that can directly convert electrical energy into heat energy to achieve cooling and heating functions has been hindered.

but now,

Researchers from the University of Houston and the Massachusetts Institute of Technology report that they have discovered a new material that works very efficiently at room temperature and hardly requires expensive tellurium (tellurium is currently the most advanced material. The main ingredient).

Researchers in the study said the material can help prevent electronic equipment, vehicles and other components from overheating. In addition, the material is very cheap, but its performance is as good as traditional and more expensive materials. In the future, researchers will work to narrow the subtle performance gap between this material and traditional materials (bismuth-tellurium alloy).

The working principle of thermoelectric materials is to use the heat flow from the hotter area to the colder area, and the thermoelectric cooling module will work according to the Peltier effect, which describes the direction of the current at the junction of two different conductors. Different, there will be heat absorption and heat release.

In addition, thermoelectric materials can also be used to convert waste heat from power plants, automobile exhaust pipes and other sources into electrical energy. And it is reported that many new materials are used in such applications, and such applications require materials to be able to work at higher temperatures.

Because the thermoelectric cooling module must work in a lower temperature environment, in such an environment, the thermoelectric conversion figure of merit coefficient ZT value of the thermoelectric module is relatively low (the coefficient depends on the temperature), so the thermoelectric cooling module causes a huge challenge. The figure of merit ZT value is an index to measure the working efficiency of thermoelectric materials. The higher the ZT value of thermoelectric materials, the better.

Despite the challenges, at least so far, such thermoelectric cooling modules still have great commercial potential, partly because they can work at lower temperatures for long periods of time, while thermoelectrics generate electricity due to high temperatures (oxidation and thermal instability). Sex) will become very complicated.

The thermoelectric cooling market is growing. According to researchers, the global thermoelectric module market value was approximately US$600 million in 2018 and is expected to reach approximately US$1.7 billion by 2027.

For decades, bismuth-tellurium alloy has been regarded as the best thermal cooling material, but researchers say that the high cost of tellurium has limited the wide application of this material. Although the cost of tellurium has dropped recently, it is still around US$50 per kilogram. In contrast, the main component of the new material developed by the researchers is magnesium, and the price of magnesium is about $6 per kilogram.

The researchers said that this new material is made of magnesium and bismuth, created in a negatively charged (n-type) form, and has the same efficiency as traditional bismuth-tellurium materials. In addition, the material's lower cost may expand thermoelectric modules for cooling applications.

In order to use the new material to make a thermoelectric module, the researchers combined it with the positive charge carriers in the traditional bismuth-tellurium alloy, so only half of the tellurium in most current modules is used, because the cost of the material is about the equipment One-third of the cost, which can save a lot of cost. In addition, the new material has better electrical contact capabilities when compared with most nanostructured materials.

Link to this article: New low-cost thermoelectric materials can cool summer auto parts

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

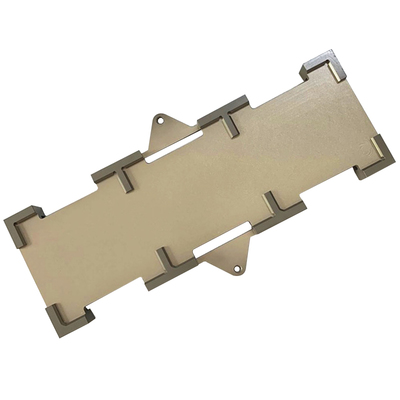

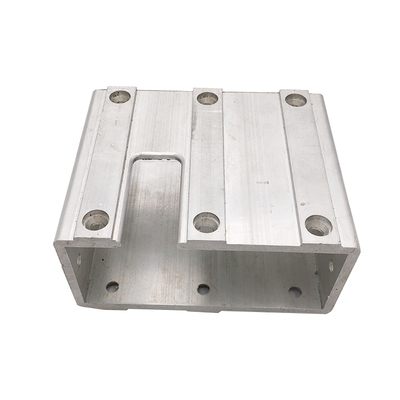

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material