Quartz glass micromachining 3D printing technology to achieve complex three-dimensional hollow microstructures

Quartz glass is a preferred material used in environments requiring long-term chemical and mechanical stability and excellent optical performance. Microfluidic chips are one of the application directions of this material. However, it is precisely because of the high thermal stability, chemical stability and mechanical hardness of quartz glass materials that it has been challenging to manufacture micro-complex three-dimensional structures in quartz glass.

3D printing disappearing template

The microstructures in fused silica glass are usually manufactured by wet chemical or dry etching processes. More complex structures can be manufactured by precision glass forming, sol-gel or replicated powder blasting. However, all these technologies can only manufacture open two-dimensional channel structures, and need to be combined with a flat substrate to manufacture simple suspended hollow microstructures (for example, microfluidic channels).

According to research papers, it is difficult to form a free-form hollow structure inside fused silica glass through common processes. Writing with a femtosecond laser and continuous etching of the irradiated area with aggressive chemicals such as hydrofluoric acid (HF) is one of the methods, but this method tends to produce long channel structures with few entrances. In the case of non-uniformity, when the tapered channel structure is manufactured, the size toward the entrance of the channel is likely to be wider. In addition, the channel length will also be limited by the etching process, because HF etching shows that the etching speed decreases with the channel length, and debris can quickly block the channel.

In order to overcome these problems, the scientific research field has explored different technologies, but these technologies are only suitable for manufacturing simple channel geometries. For example, in order to overcome the demand for aggressive etching solutions, some researchers have developed liquid-assisted ablation femtosecond laser writing. This technology produces components with significant surface roughness, so post-processing is required to achieve optical quality. s surface.

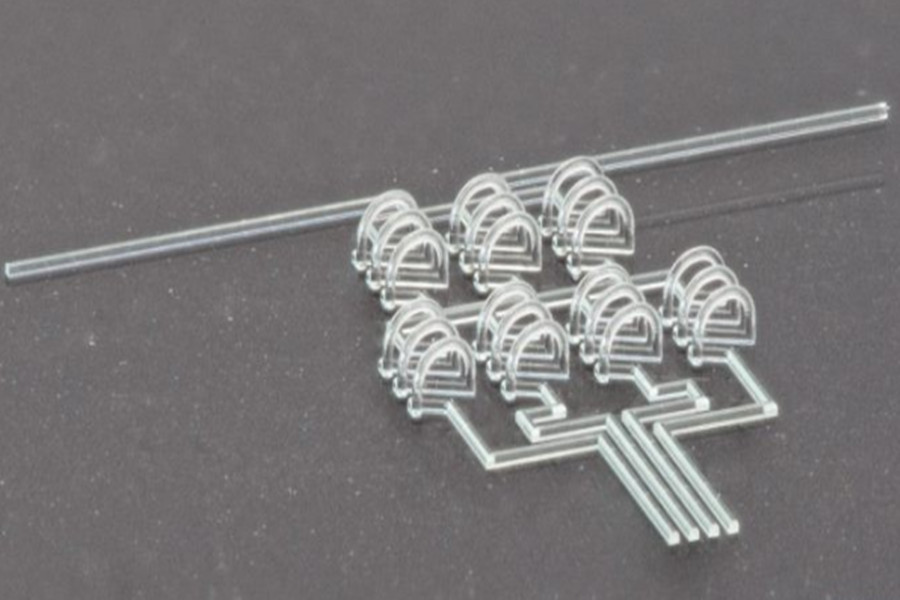

The research paper describes a process that can generate complex 3D microstructures of quartz glass. Specifically, researchers used Nanoscribe two-photon 3D printing technology to create a sacrificial template that generates quartz glass microfluidic channels. The micro 3D printed sacrificial template uses polymerization Material manufacturing.

Researchers cast the 3D printed microstructure in a liquid nanocomposite glass material, and then used UV light to cure it on top of the polymer template. Then the structure is heat-treated to convert the nanocomposite material into fused silica glass, and the 3D printing template is melted from the inside. In this process, the temperature is as high as 1,300 degrees Celsius, and finally a silica glass structure with hollow complex microchannels is manufactured.

In the process of researching this process, the research team successfully manufactured channels as small as 7 microns in diameter. Through precision test components such as quartz glass mixers, the research team demonstrated the feasibility of this combined micro 3D printing technology in the field of manufacturing complex glass products, and also provided feasibility for the micro processing of glass materials.

Link to this article:

Reprint Statement: If there are no special instructions, all articles on this site are original. Please indicate the source for reprinting:https://www.cncmachiningptj.com

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

PTJ® provides a full range of Custom Precision cnc machining china services.ISO 9001:2015 &AS-9100 certified.

Machining shop specializing in fabrication services for construction and transportation industries. Capabilities include plasma and oxy-fuel cutting, Tailored machining, MIG and Custom Aluminum Cnc Precision Milling Welding Jig Fixture, roll forming, assembly, Lathe machining stainless steel cnc machine shaft, shearing, and CNC Swiss Machining services. Materials handled include carbon and Passivation Stainless Steel Machining Cover Plate Parts.

Tell us a little about your project’s budget and expected delivery time. We will strategize with you to provide the most cost-effective services to help you reach your target,You are welcome to contact us directly ( [email protected] ) .

- 5 Axis Machining

- Cnc Milling

- Cnc Turning

- Machining Industries

- Machining Process

- Surface Treatment

- Metal Machining

- Plastic Machining

- Powder Metallurgy Mold

- Die Casting

- Parts Gallery

- Auto Metal Parts

- Machinery Parts

- LED Heatsink

- Building Parts

- Mobile Parts

- Medical Parts

- Electronic Parts

- Tailored Machining

- Bicycle Parts

- Aluminum Machining

- Titanium Machining

- Stainless Steel Machining

- Copper Machining

- Brass Machining

- Super Alloy Machining

- Peek Machining

- UHMW Machining

- Unilate Machining

- PA6 Machining

- PPS Machining

- Teflon Machining

- Inconel Machining

- Tool Steel Machining

- More Material